Hysteresis type yarn tension adjusting device

A yarn tension and adjusting device technology, which is applied in the textile field, can solve problems such as increased hairiness, yarn extrusion damage, and yarn strength decrease, and achieves high operation selectivity and matching, stable tension control, and reduced bad friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical solutions of the present invention clearer, the present invention will be further described below with reference to the specific embodiments of the accompanying drawings.

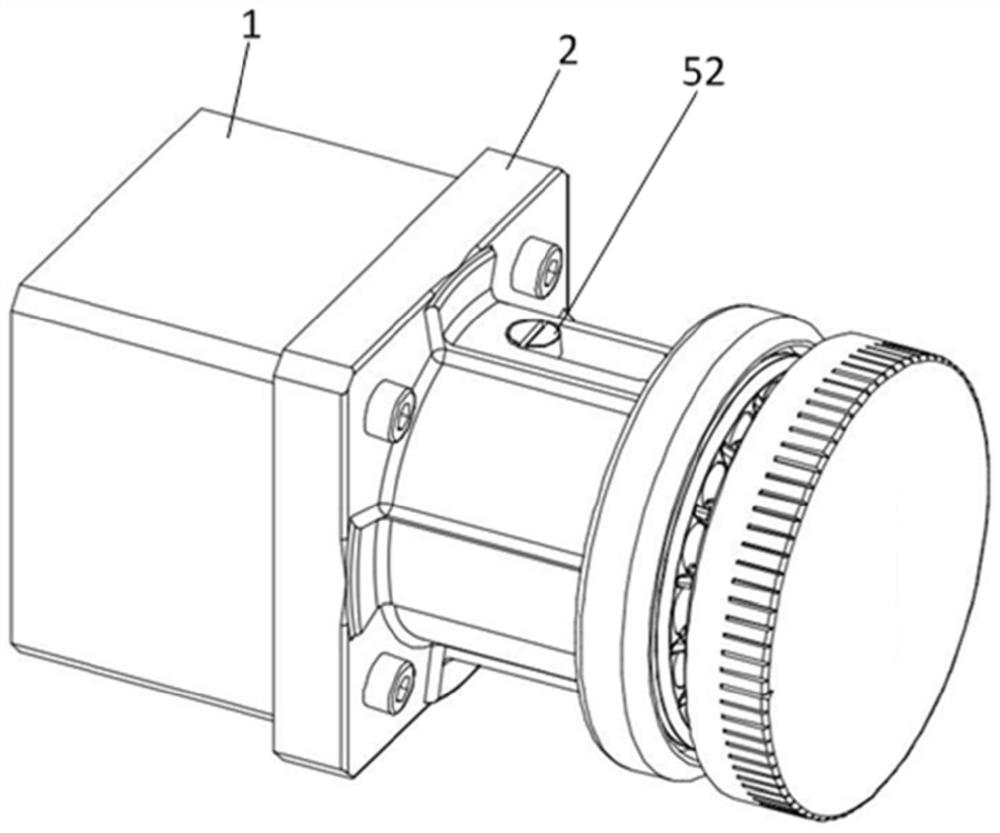

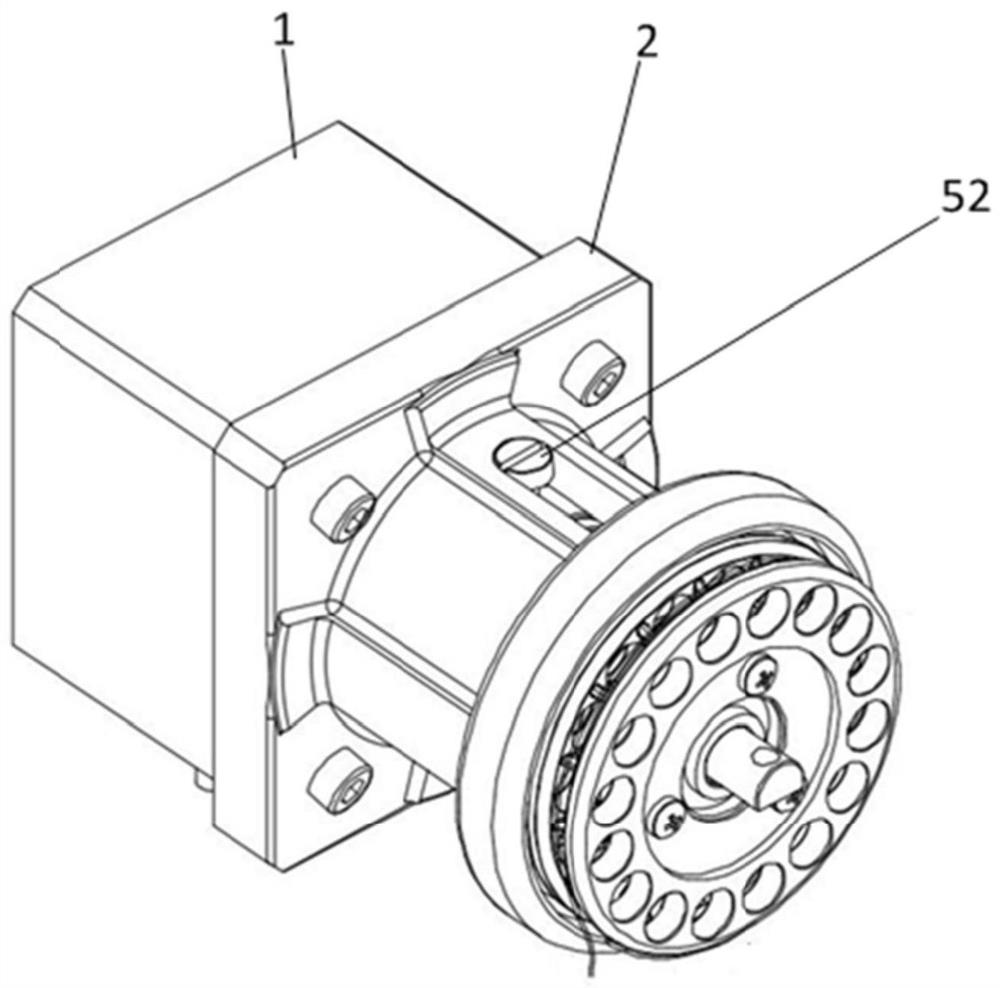

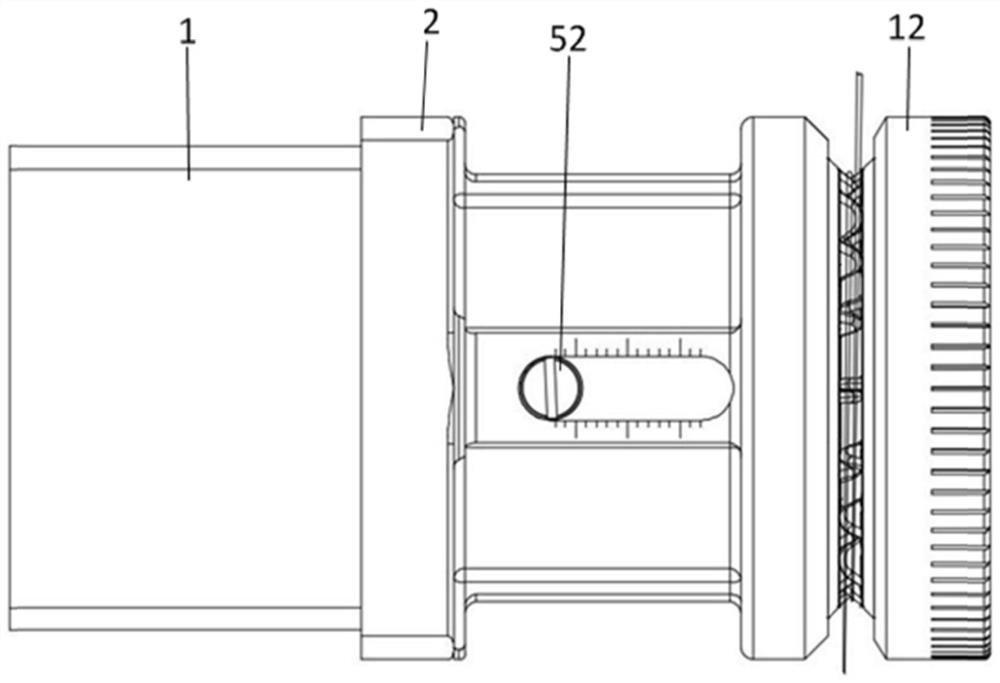

[0018] like Figure 1-6 As shown, a hysteresis yarn tension adjusting device according to an embodiment of the present invention includes a motor 1, and a cover 2 is provided on the outer surface of the motor 1 in the direction of the motor shaft 13, and is fixedly connected to each other by bolts 22, The outer surface of the casing 2 is provided with a long opening 21, and the rotating shaft 4 is a hollow structure as a whole. , the bottom of the motor shaft 13 is spliced with a gasket 3, the side of the gasket 3 is located on the outer surface of the motor shaft 13 is spliced with a rotating shaft 4, and is fixedly connected to each other through the positioning pin 41 and the positioning hole 44, so that the rotation The shaft 4 and the motor shaft 13 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com