Touch screen production equipment and processing method thereof

A technology of production equipment and processing method, which is applied to touch screen production equipment and its processing field, can solve the problems of broken glass and weak adsorption of adsorbents, and achieves the advantages of improving production efficiency, reducing manual material reclaiming operation steps, and improving material reclaiming efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

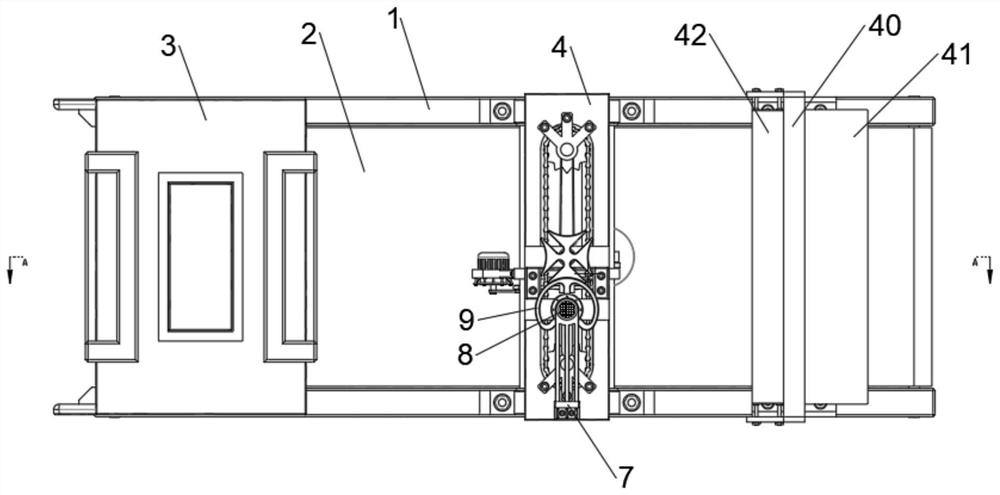

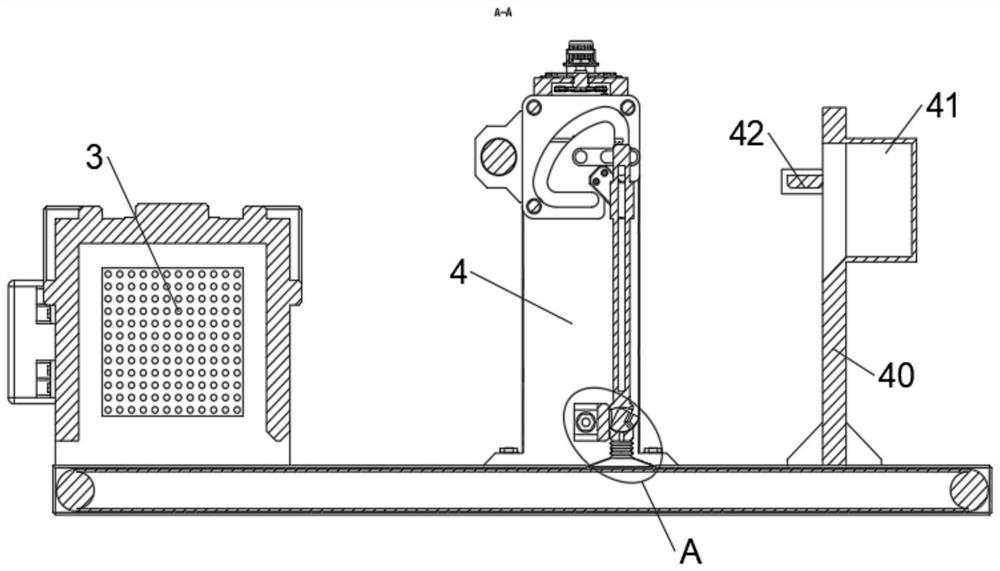

[0040] Please refer to figure 1 and Figure 10 As shown, a touch screen production equipment includes a work frame 1, the inner side of the work frame 1 is provided with a transmission device 2 for driving the screen glass, the work frame 1 is fixedly installed with a cutting device 3 for cutting the screen glass, and the transmission device 2 and The cutting device 3 is electrically connected with the equipment control device. The work frame 1 is fixedly connected with a support frame 4 through bolts. The support frame 4 is provided with a transmission slot 5 for intermittent transmission. The transmission assembly, the support frame 4 is fixedly connected with a first fixing bracket 7 for supporting by bolts, the inner side of the first fixing bracket 7 is provided with an intermittent component, and the inside of the support frame 4 is provided with a collection mechanism for collecting screen glass, the collection mechanism Including movable components, driving components...

Embodiment 2

[0043] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 9 As shown, the intermittent assembly includes a fixed plate 6, a first motor 8, a rotating ring 9, a push rod 10, a first rotating shaft 11 and a sheave 12, the fixed plate 6 is fixedly installed on the top of the support frame 4, and the first motor 8 is fixed Installed on the inner side of the first fixing bracket 7, the first motor 8 is electrically connected to the equipment using the power supply, the output end of the bottom of the first motor 8 is fixedly connected with a rotating ring 9 for stopping rotation, and the rotating ring 9 is fixedly connected with a rotating ring 9 for pushing. The rotating push rod 10, the first rotating shaft 11 is rotatably connected to the fixed plate 6, the sheave 12 is fixedly connected to the top of the first rotating shaft 11, and the outer wall of the sheave 12 and the outer wall of the rotating ring 9 abut each other.

[0044] The trans...

Embodiment 3

[0048] Please refer to Figure 4 , Figure 7 and Figure 8 As shown, the drive assembly includes a second motor 22, a first rotating rod 23, a toothed rod 24, a third rotating shaft 25, a second gear 26 and a fitting block 27, and the outer wall of the movable plate 20 is fixedly connected with a second drive for driving. The motor 22 and the second motor 22 are electrically connected with the equipment using a power supply, one end of the first rotating rod 23 is fixedly connected to the output end of the second motor 22, and the other end of the first rotating rod 23 is fixedly connected with a toothed rod for reciprocating transmission 24. The third rotating shaft 25 is rotatably connected to the middle of the movable plate 20, the second gear 26 is fixedly connected to the outer side of the third rotating shaft 25, the top of the second gear 26 meshes with the bottom of the gear rod 24, and the fitting block 27 It is rotatably connected to the outer wall of the third rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com