Sleeving packaging machine with precise counting and material arranging functions

A packaging machine and material-arranging technology, applied in the field of food packaging, can solve the problems of difficulty in further improving processing efficiency, manual labor for inner and outer bags, and multiple inner bags, and achieves continuous and rapid feeding operation, good economical Benefit, accurate and efficient counting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further illustrated by the following examples.

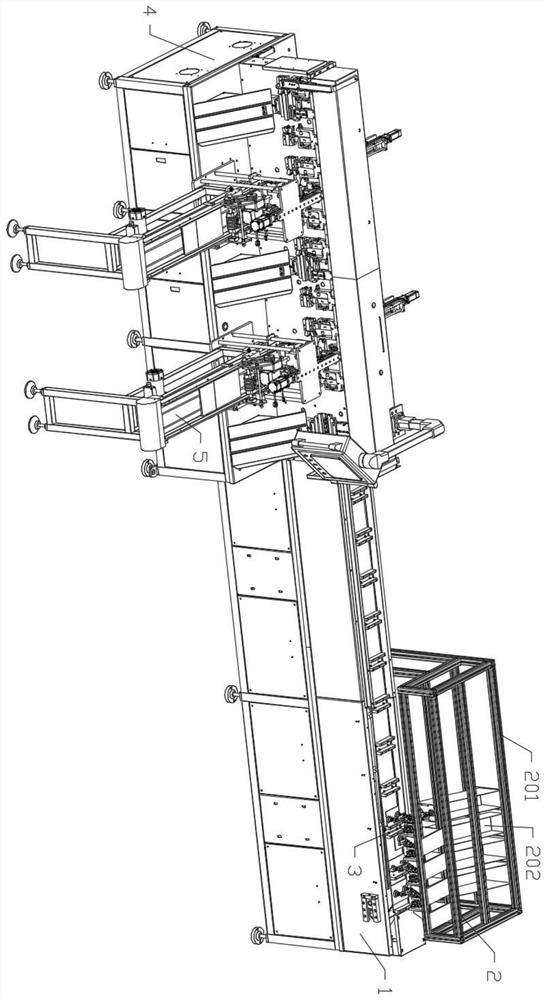

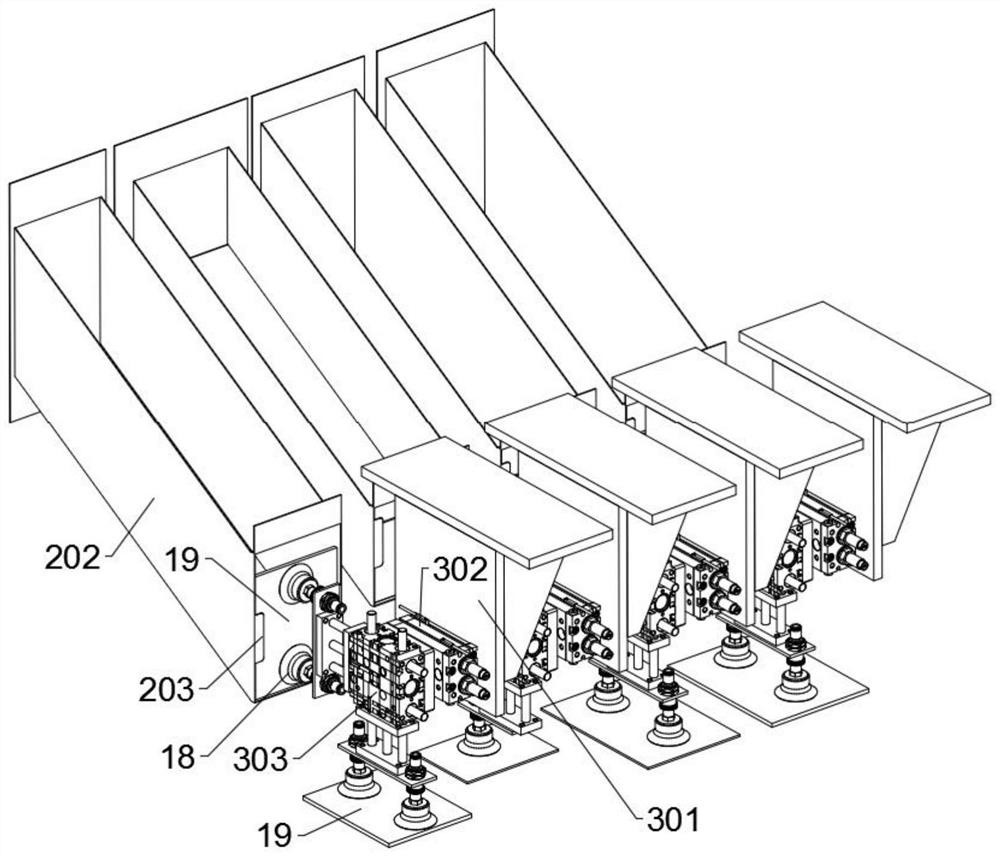

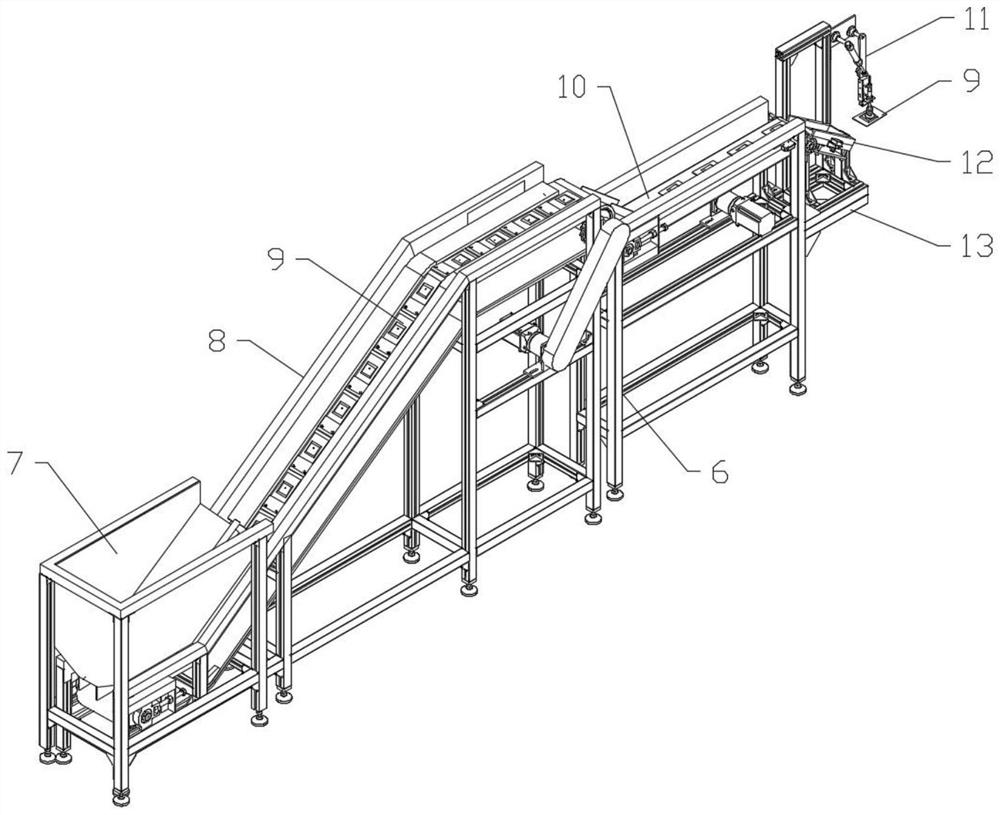

[0034] The packaged packaging machine with the function of accurate counting and material sorting includes a filling machine. One side of the frame 4 of the filling machine is connected to the feeding mechanism 1 of the chain structure. The front end of the frame 4 is provided with an outer bag conveyor belt 5. The said The feeding mechanism 1 is connected to the feeding assembly 2, and the feeding assembly 2 includes inclined feeding boxes 202 arranged in an array. The bottom end of the feeding box 202 is provided with an inner bag suction assembly 3 to pack the inner packaging of the feeding box 202. The bag 19 is transferred into the material box of the feeding mechanism 1; the outer bag conveyor belt 5 is connected to the outer bag material sorting and feeding mechanism, and the outer bag material sorting and feeding mechanism includes a hopper 7, and the hopper 7 is followed by a chain elevato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com