Nodular cast iron platform surface polishing treatment system

A platform surface and treatment system technology, applied in the field of ductile iron platform surface polishing treatment system, can solve the problems of reducing polishing agent, residual iron filings, affecting polishing effect, etc., and achieve the effect of reducing wear and reducing contact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

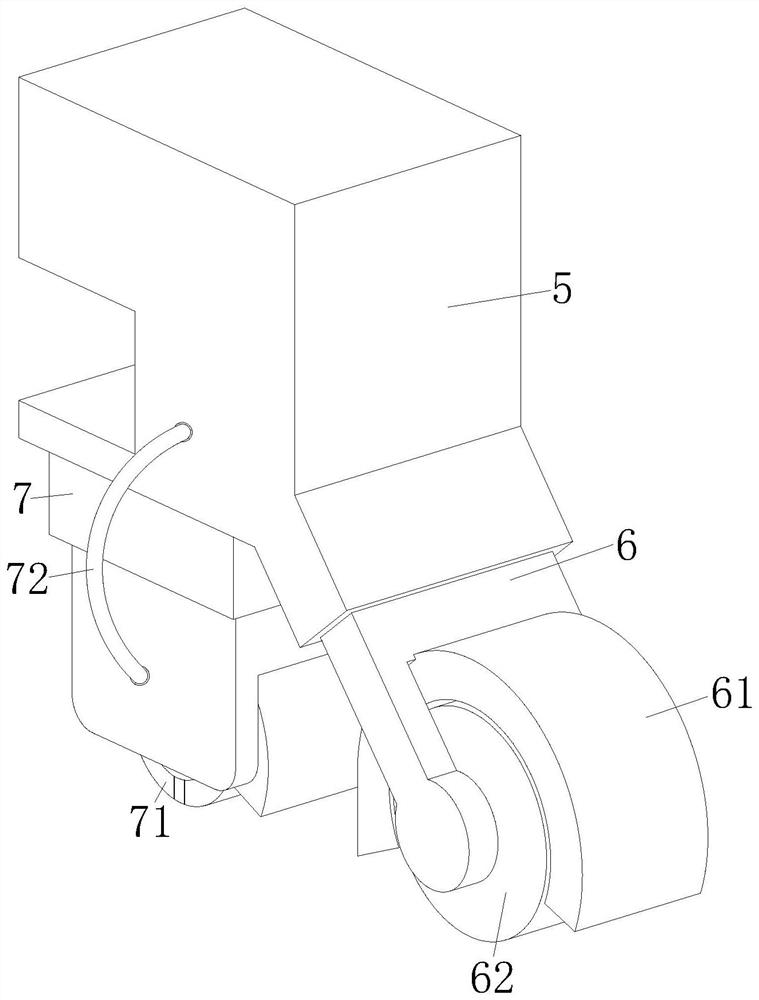

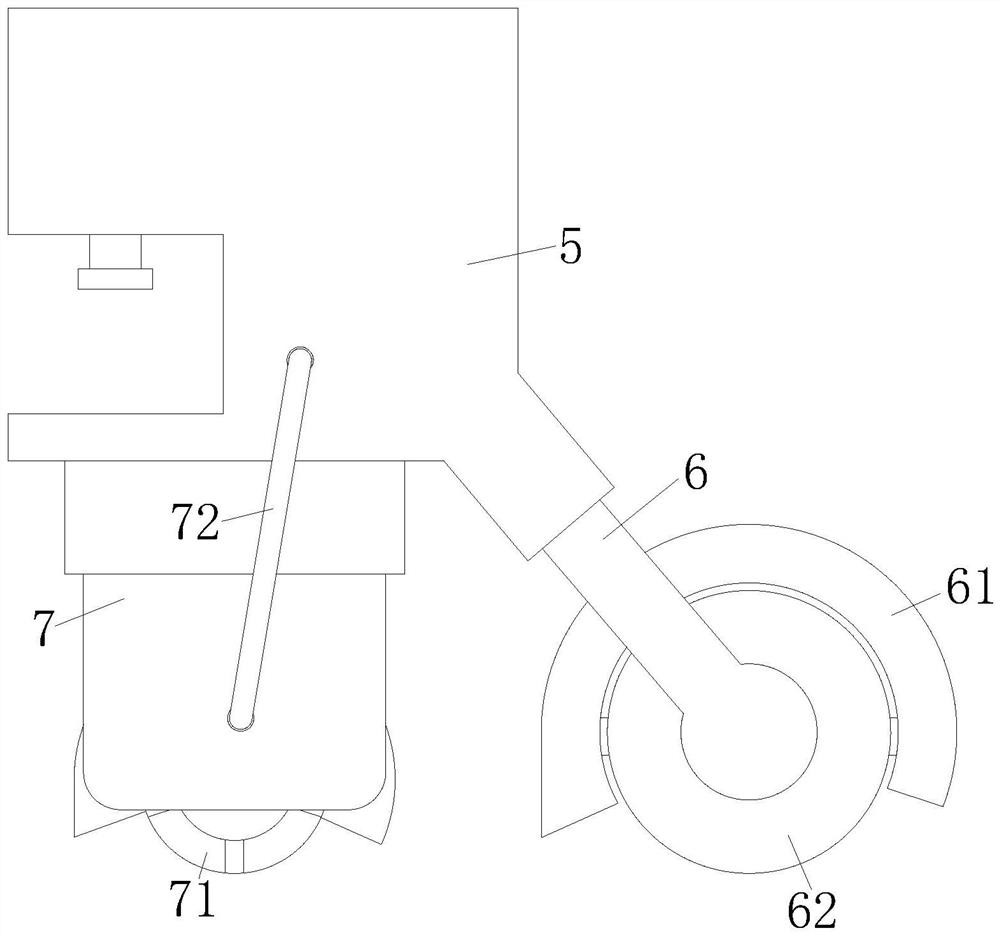

[0058] As an embodiment of the present invention, the feeding assembly includes:

[0059] A guide pipe 713, the guide pipe 713 is arranged on the inner side of the installation groove 711, and a gap is formed at the adjacent end of the guide pipe 713 and the polishing groove 712;

[0060] A telescopic hose 72, the upper end of the telescopic hose 72 is fixedly connected with the storage box 51, and the telescopic hose 72 is communicated with the storage box 51, and a cavity is opened inside the polishing wheel 71, The conduit 713 communicates with the telescopic hose 72 through a cavity.

[0061] Further, because the conduit 713 communicates with the telescopic hose 72 through the inner cavity of the polishing wheel 71, the cavity is located at the central axis of the polishing wheel 71, and the connection between the cavity and the telescopic hose 72 is a rotational connection, so when polishing When the wheel 71 rotates, the connecting part of the telescopic hose 72 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com