Hydraulic engineering desilting device and desilting method

A dredging device and water conservancy engineering technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as low work efficiency, large environmental secondary pollution, and environmental pollution around roads, so as to improve work efficiency, The effect of preventing secondary pollution and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

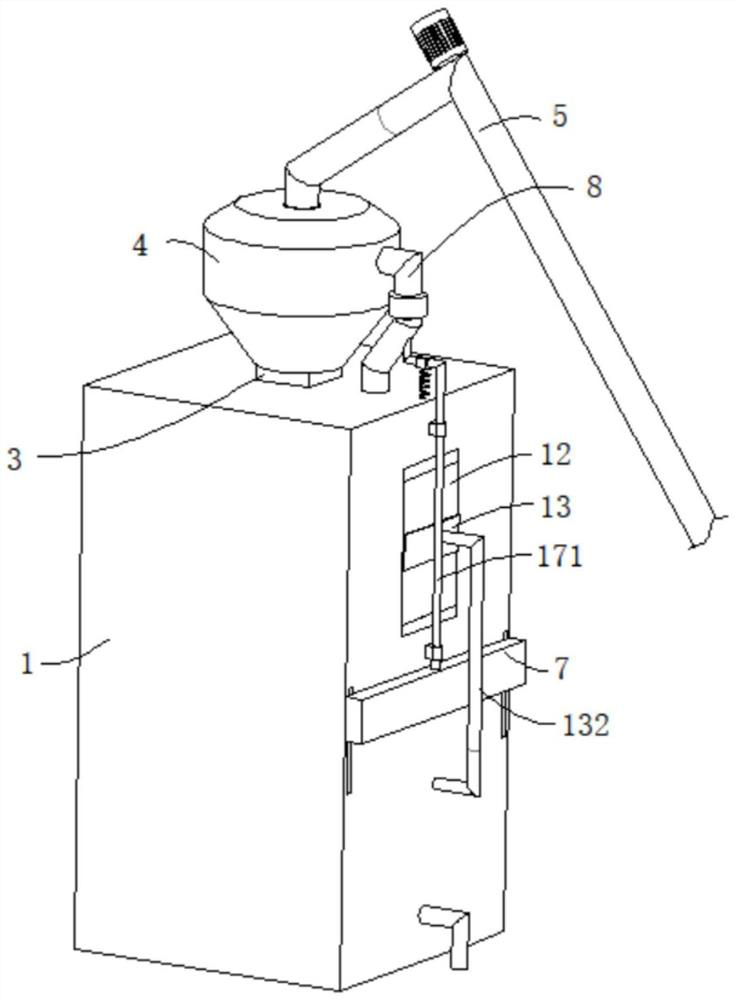

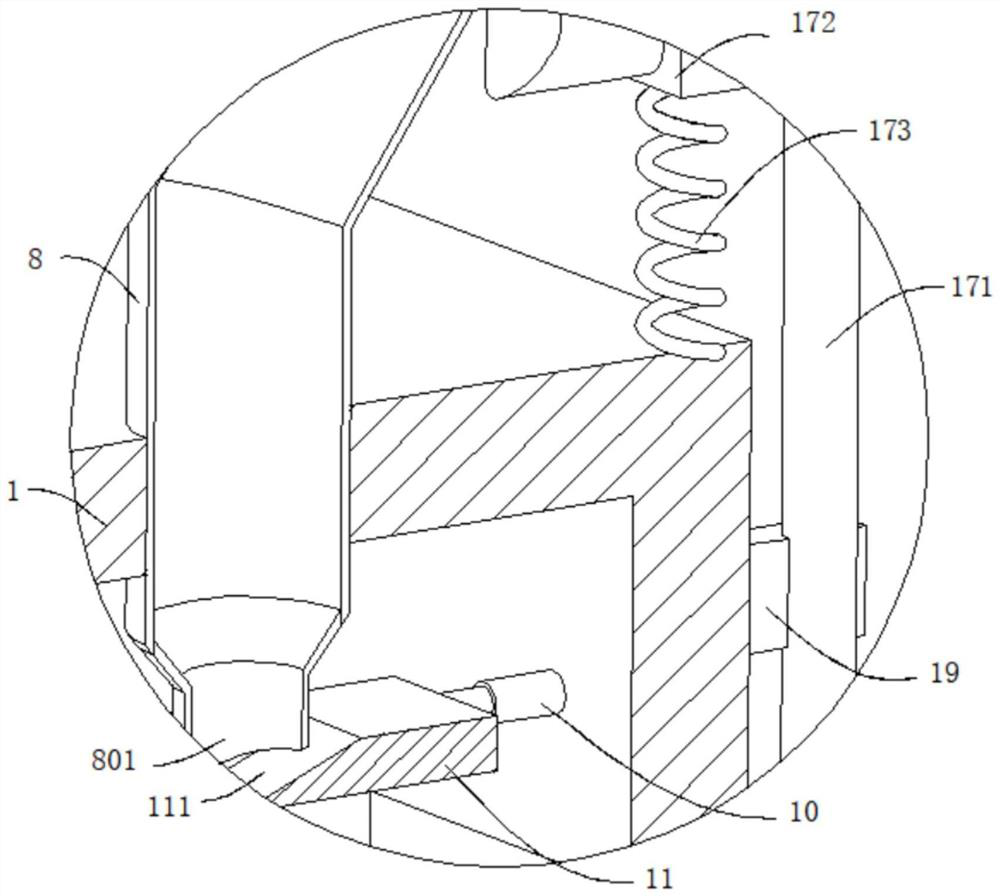

[0039] refer to figure 1 , figure 2 and Figure 4 , a water conservancy project dredging device, comprising a filter box 1, the filter box 1 is provided with an inclined filter screen plate 2, the top of the filter box 1 is connected with a connecting pipe 3, and the connecting pipe 3 is connected with a buffer shell 4, One end of the buffer casing 4 away from the connecting pipe 3 is connected with a sludge suction pipe 5, a pump body is arranged on the sludge suction pipe 5, a sludge outlet 301 is opened at the bottom of the connection pipe 3, and a sludge discharge port 301 is provided in the filter box 1 for plugging and discharging sludge. The floating component of the port 301, the filter box 1 is provided with a clamping component for restricting the movement of the floating component, the filter box 1 is provided with a silt discharge port 6, and the silt discharge port 6 is placed at the bottom end of the screen plate 2, and the silt discharge port A baffle plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com