Automatic extraction equipment for cosmetics

A technology for extraction equipment and cosmetics, applied in the field of automatic extraction equipment for cosmetics, can solve the problems of insufficient extraction adequacy of ingredients and insufficient refinement of raw materials for extracted ingredients, and achieve the effect of improving extraction effect and sufficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

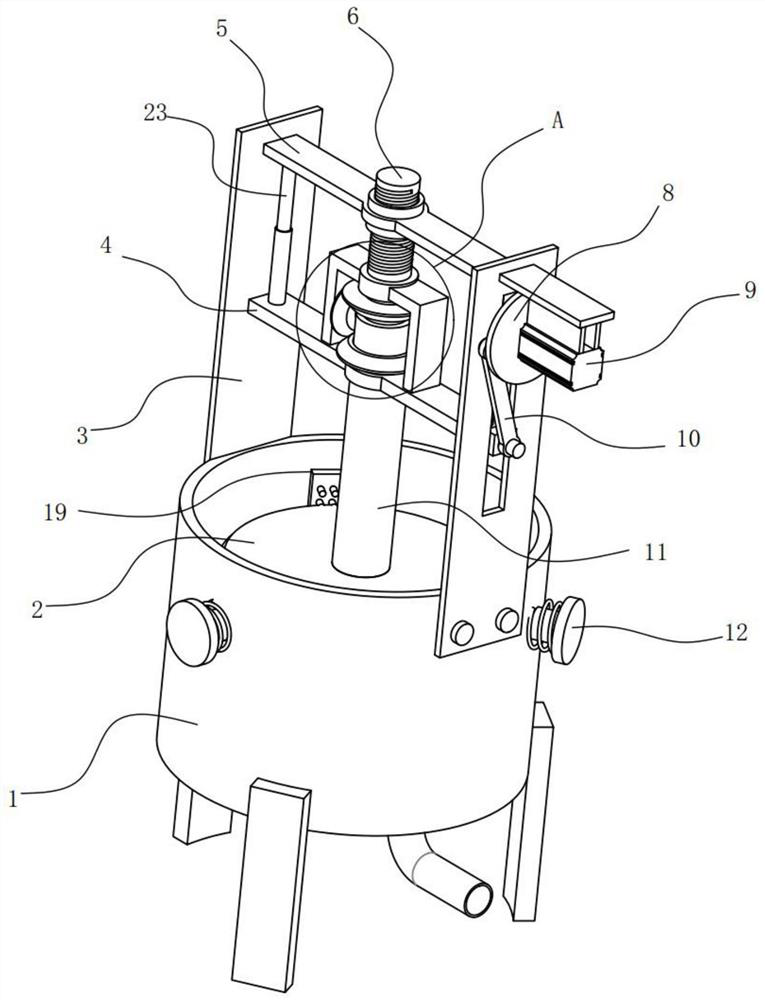

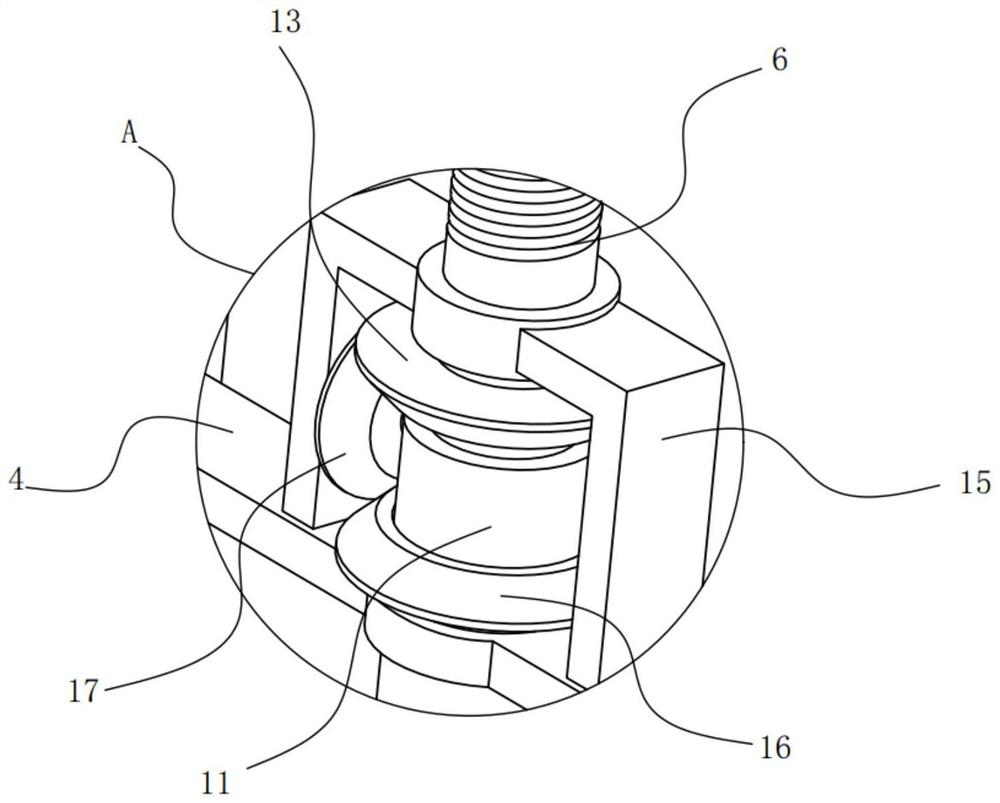

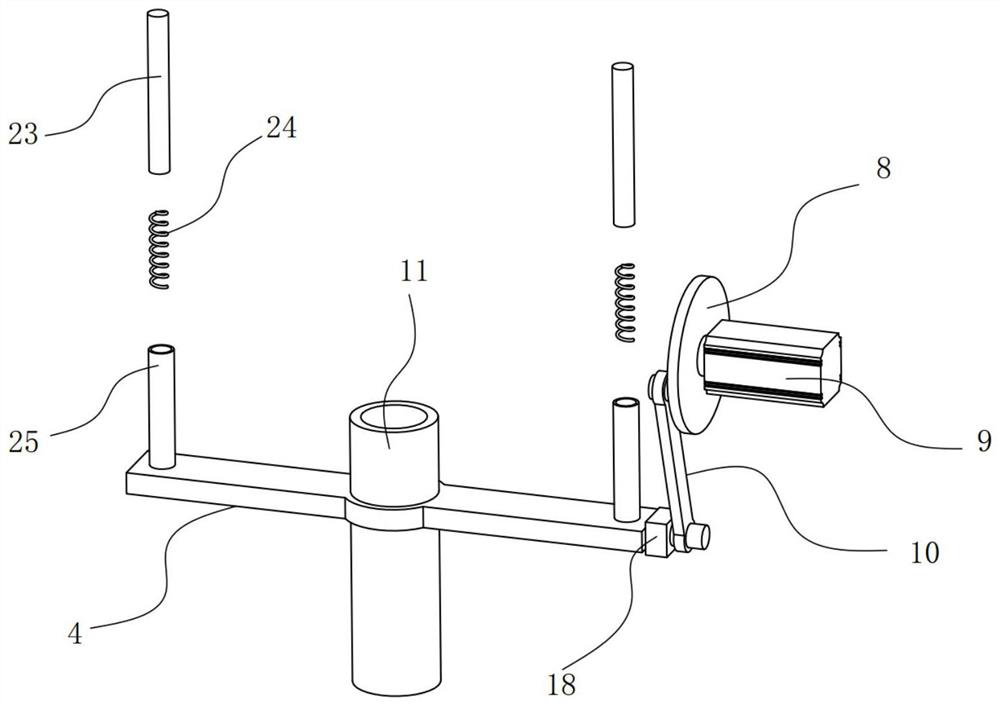

[0024] see Figure 1-5 , an automatic extraction equipment for cosmetics, including an extraction cylinder 1, an extraction mesh bucket 2 is arranged in the extraction cylinder 1, a support frame 3 is fixed on the extraction cylinder 1, a horizontal plate 5 is installed on the top of the support frame 3, and the support frame 3 is vertical A sliding frame 4 is installed in a straight slide, a rotating sleeve 11 is rotatably installed on the sliding frame 4, a rotating shaft 6 is vertically penetrated in the rotating sleeve 11, a connecting frame 15 is fixed on the sliding frame 4, and the rotating shaft 6 is rotatably installed on the rotating sleeve 11. On the connecting frame 15, a rotating assembly for driving the rotating shaft 6 and the rotating sleeve 11 to reversely rotate is installed on the connecting frame 15;

[0025] The extraction mesh bucket 2 includes a top plate 14 , which is coaxially fixed with the rotating sleeve 11 , and a rotating shaft 6 extends into the ...

Embodiment 2

[0033] see Figure 1-5 , On the basis of Embodiment 1, in addition, a vertical brush plate 19 is installed on the inner wall of the extraction cylinder 1, and the brush plate 19 is arranged in close contact with the outer wall of the extraction mesh bucket 2, and between the brush plate 19 and the extraction cylinder 1 An elastic push component is connected.

[0034] The elastic pushing assembly includes a sliding column 21 slidably installed on the extraction cylinder 1 , one end of the sliding column 21 is fixedly connected with the brush plate 19 , and the other end of the sliding column 21 is fixed with a limit plate 12 , which is connected to the extraction cylinder 1 . A spring coil 20 is fixed therebetween.

[0035] Under the elastic action of the spring ring 20, the limiting plate 12 drives the sliding column 21 to elastically push the brush plate 19, so that the brush plate 19 is pressed against the outer side wall of the extraction mesh bucket 2, and the extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com