Preparation method of high-sweetness compound stevioside microcapsule capable of increasing lactation ability of livestock and poultry

A technology of compound stevia and stevia, which is applied in the fields of animal husbandry, additional food elements, and the molding or processing of animal feed, can solve the problems that affect the attractiveness and palatability of stevia, stevia is easy to absorb moisture and agglomerate, and cannot be mixed well. and other problems, to achieve the effect of promoting rapid recovery of animals, rapid recovery of anti-stress animals, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

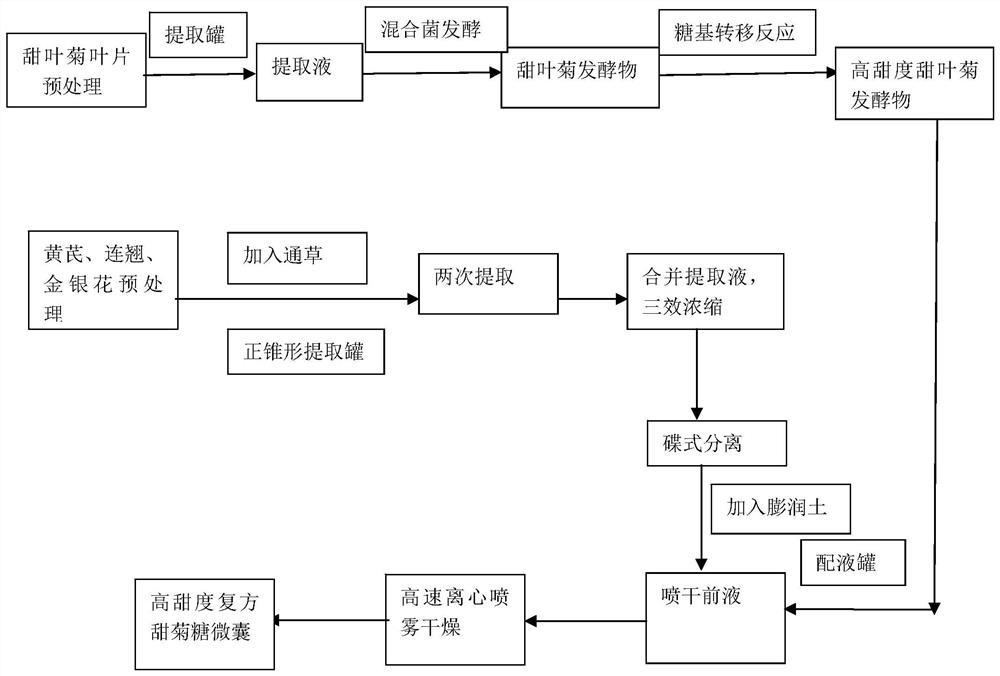

Method used

Image

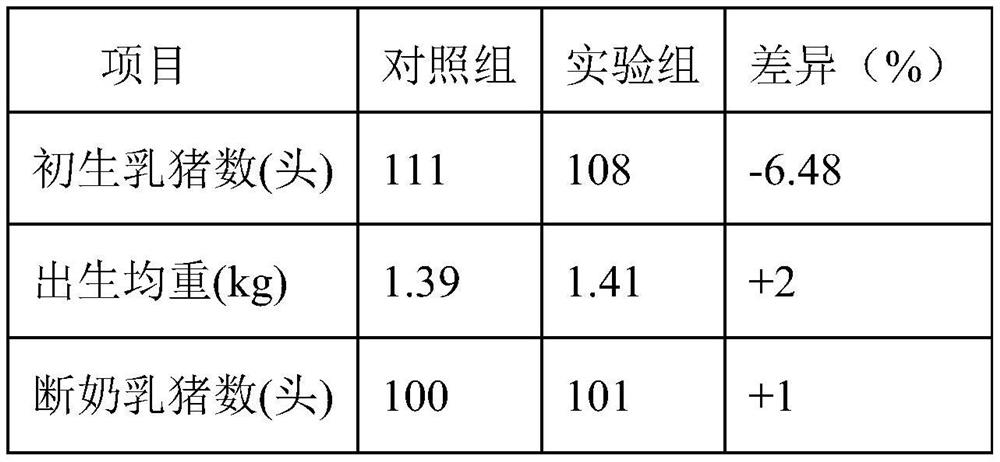

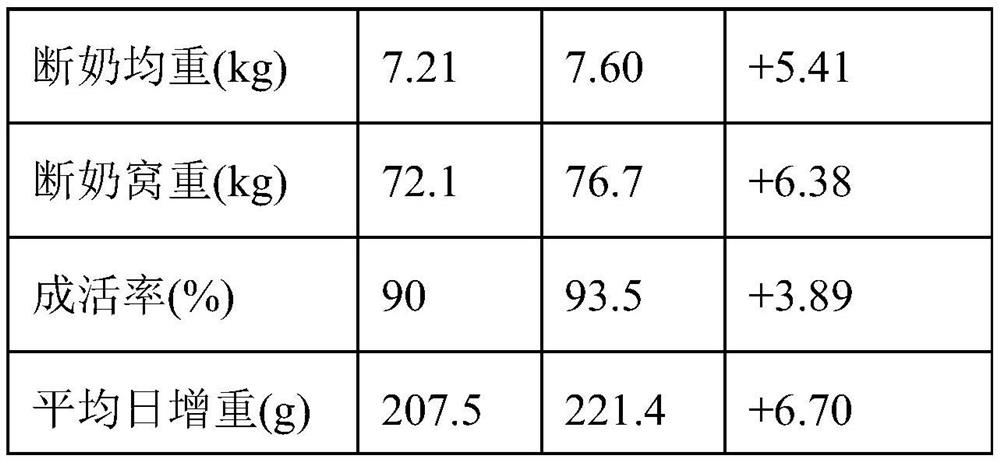

Examples

Embodiment 1

[0039] A slow-release high-sweetness compound stevia microcapsule for increasing the lactation power of livestock and poultry, the method comprising the steps of:

[0040] (1) Add 100 kilograms of stevia leaves into the extraction tank, add 800 kilograms of water, extract at 85°C for 3 hours, filter and collect the extract, add 800 kilograms of water to the filter residue, and extract at 90°C. 2h, the extract was collected by filtration, and the two extracts were combined;

[0041] Collect the extract and put it into the liquid fermenter, add compound bacteria, based on 1 kg of stevioside extract, the addition of Saccharomyces cerevisiae is 0.2g10 billion CFU / g, the addition of Bacillus is 0.2g100 million CFU / g, lactic acid is 0.2g100 million CFU / g The addition amount of Bacillus was 0.2g 10 billion CFU / g, the addition amount of Clostridium aerogenes was 0.2g 10 billion CFU / g, the fermentation time was 80h, the fermentation pH was 3.6, and the temperature was 55℃. 50kg of uri...

Embodiment 2

[0049] A slow-release high-sweetness compound stevia microcapsule for increasing the lactation power of livestock and poultry, the method comprising the steps of:

[0050] (1) Add 150 kilograms of stevia leaves into the extraction tank, add 1300 kilograms of water, extract for 4 hours at 88°C, filter and collect the extract, add 1200 kilograms of water to the filter residue, and extract at 95°C 3h, the extract was collected by filtration, and the two extracts were combined;

[0051] Collect the extract and put it into the liquid fermenter, add compound bacteria, based on 1 kg of stevia extract, the addition of Saccharomyces cerevisiae is 0.25g 10 billion CFU / g, the addition of Bacillus is 0.25g 10 billion CFU / g, lactic acid is 0.25g 10 billion CFU / g The addition amount of Bacillus is 0.25g 10 billion CFU / g, the addition amount of Clostridium aerogenes is 0.25g 10 billion CFU / g, the fermentation time is 100h, the fermentation pH value is 3.5, and the temperature is 58℃. 80kg o...

Embodiment 3

[0059] A slow-release high-sweetness compound stevia microcapsule for increasing the lactation power of livestock and poultry, the method comprising the steps of:

[0060] (1) Add 200 kilograms of stevia leaves into the extraction tank, add 1800 kilograms of water, extract at 90°C for 5 hours, filter and collect the extract, add 1,600 kilograms of water to the filter residue, and extract at 93°C 2h, the extract was collected by filtration, and the two extracts were combined;

[0061] Collect the extract and put it into the liquid fermenter, add compound bacteria, based on 1 kg of stevia extract, the addition of Saccharomyces cerevisiae is 0.3g10 billion CFU / g, the addition of Bacillus is 0.3g100 million CFU / g, lactic acid is 0.3g10 billion CFU / g The addition amount of Bacillus is 0.3g 10 billion CFU / g, the addition amount of Clostridium aerogenes is 0.3g 10 billion CFU / g, the fermentation time is 95h, the fermentation pH value is 3.8, and the temperature is 60℃. 70kg of uridi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com