Chitosan plant essential oil microcapsule composite coating preservative as well as preparation method and application thereof

A technology of coating preservatives and plant essential oils, which is applied in the fields of application, preservation of fruits and vegetables, and protection of fruits/vegetables with a coating protective layer. It can solve the problems of short storage time, stratification of phases, safety pollution of chemical preservatives, etc. problems, to achieve the effect of simple treatment, mild reaction conditions, and prolonging the fresh-keeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

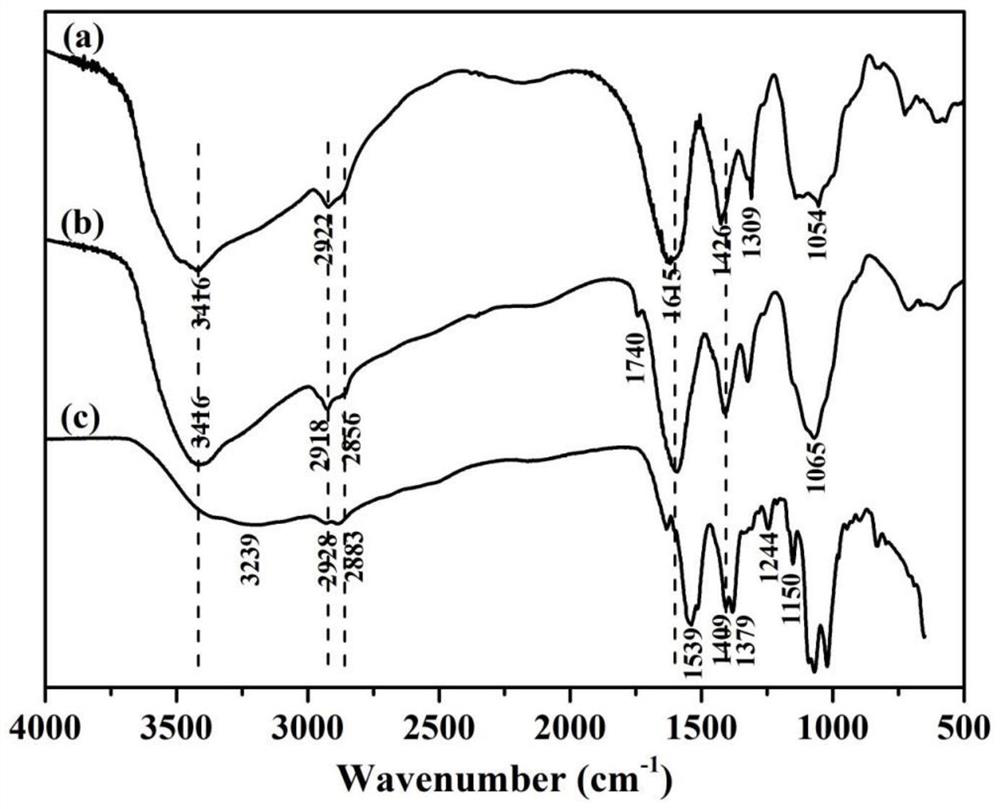

[0045] 2. The present invention discloses a preparation method of the above-mentioned chitosan-polyphenol derivative, comprising the following steps:

[0046] (1) Dissolve carboxymethyl chitosan in deionized water to form a carboxymethyl chitosan solution, add a phase transfer catalyst, stir and mix with epoxy vegetable oil and photocatalyst dissolved in an organic solvent under UV light , dialysis, freeze-drying to obtain UV photocatalyzed carboxymethyl chitosan vegetable oil-based copolymer;

[0047] Among them, the viscosity average molecular weight of carboxymethyl chitosan is 3.0×10 3 ~2.5×10 5 , the degree of deacetylation is greater than or equal to 90%, the degree of carboxylation is greater than or equal to 80%, and the concentration of the carboxymethyl chitosan solution is 1.0-10.0 mg / mL. The mass ratio of the phase transfer catalyst to carboxymethyl chitosan is 1:5 to 1:20, the mass ratio of epoxy vegetable oil to carboxymethyl chitosan is 1:1 to 5:1, and the epo...

Embodiment 1

[0073] (1) Set the viscosity average molecular weight to 3.0×10 3 , 1.0 g of carboxymethyl chitosan with a degree of deacetylation of 90% and carboxymethylation of 80% was dissolved in 100 mL of deionized water, and 0.2 g of tetrabutylammonium bromide (TBAB) was added as a phase transfer catalyst, mixed evenly. Then, 1.0 g of epoxidized soybean oil with an epoxy value of 6.6 was dissolved in 10 mL of acetone, and 0.1 g of a cationic photoinitiator triarylsulfonium salt was added. The above solution was stirred and mixed evenly, placed under 1000W UV light, and reacted with magnetic stirring at a speed of 1000r / min for 1h, dialyzed in a 5% ethanol aqueous solution for 48h (the molecular weight of the dialysis bag was 2000), freeze-dried for 24h, That is, the carboxymethyl chitosan epoxy soybean oil-based copolymer is obtained.

[0074] (2) 0.322 g of carboxymethyl chitosan epoxidized soybean oil-based copolymer and 0.161 g of 1-hydroxybenzotriazole (HOBt) were stirred in 100 ...

Embodiment 2

[0081] (1) Set the viscosity average molecular weight to 2.5×10 5 , 0.8 g of carboxymethyl chitosan with a degree of deacetylation of 90% and carboxymethylation of 85% was dissolved in 100 mL of deionized water, and 0.04 g of benzyltriethylammonium chloride (TEBA) was added as a phase transfer catalyst ,well mixed. Then, 1.0 g of epoxidized tung oil with an epoxy value of 5.8 was dissolved in 10 mL of acetone, and 0.036 g of acidic ionic liquid N-(4-sulfonic acid)butyltrimethylamine hydrogen sulfate was added. The above solution was stirred and mixed evenly, placed under 100W UV light, and reacted with magnetic stirring at a speed of 1000r / min for 5h, dialyzed in an aqueous solution of 5% ethanol for 24h (the molecular weight of the dialysis bag was 15000), freeze-dried for 48h, That is, the carboxymethyl chitosan epoxy tung oil-based copolymer is obtained.

[0082] (2) Mix 0.322g carboxymethyl chitosan epoxy tung oil-based copolymer with 1.610g benzotriazole-N,N,N',N'-tetra...

PUM

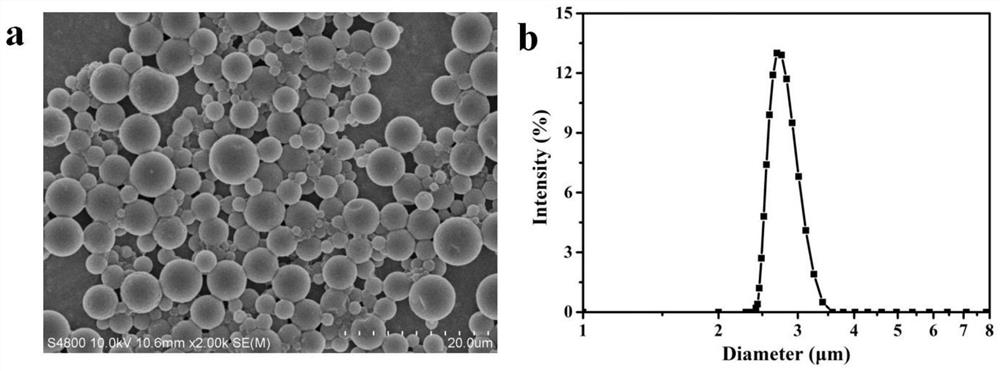

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com