Method and device for testing vibration durability of multi-axial rack

A durability test, multi-axial technology, applied in vibration test, measuring device, vehicle test, etc., can solve the problems of shortening the development and verification cycle, low accuracy of bench vibration durability test results, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

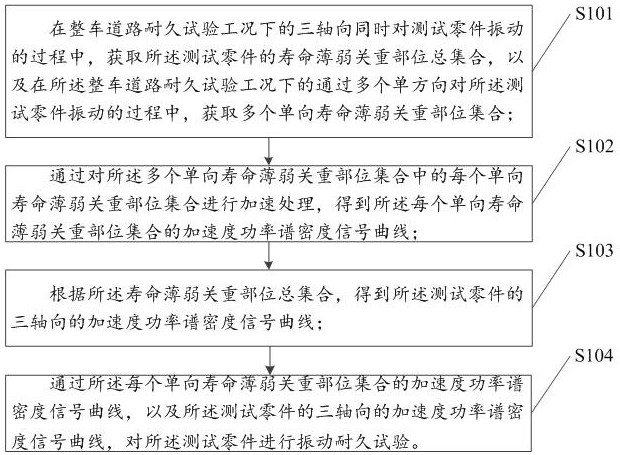

[0044] The first embodiment of the present invention provides a test method for vibration durability of a multi-axial bench, such as figure 1 shown, including:

[0045]S101, in the process of simultaneously vibrating the test parts in three axes under the vehicle road durability test condition, obtain the total set of the life weak critical parts of the test part, and obtain the test parts under the vehicle road durability test condition During the process of vibrating the test part in multiple unidirectional directions, multiple sets of unidirectional weak and critical parts of life are obtained;

[0046] S102, by performing acceleration processing on each one-way weak and critical part set in the plurality of one-way weak and critical parts sets, obtain the acceleration power spectral density of each one-way weak and critical part set signal curve;

[0047] S103, obtaining a triaxial acceleration power spectral density signal curve of the test part according to the total s...

Embodiment 2

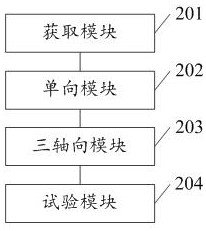

[0285] Based on the same inventive concept, the second embodiment of the present invention also provides a multi-axial bench vibration durability test device, such as figure 2 shown, including:

[0286] The obtaining module 201 is used to obtain the total set of the life weak critical parts of the test part during the process of simultaneously vibrating the test part in three axes under the vehicle road durability test condition, and the durability on the vehicle road In the process of vibrating the test part in multiple unidirectional directions under the test condition, multiple sets of unidirectional weak and critical parts of life are obtained;

[0287] The one-way module 202 is configured to perform accelerated processing on each one-way weak and critical part set in the plurality of one-way weak and critical parts sets to obtain the each one-way weak and critical part set The acceleration power spectral density signal curve of ;

[0288] The triaxial module 203 is use...

Embodiment 3

[0309] Based on the same inventive concept, a third embodiment of the present invention also provides a computer device, including a memory, a processor, and a computer program stored in the memory and running on the processor, when the processor executes the program The steps for implementing any of the above-described test methods for multiaxial gantry vibration durability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com