Brewing device testing device and control method thereof

A test device and brewer technology, which is applied in the field of brewers, can solve the problems of not fully meeting the test requirements, inaccurate test results, and high test costs, and achieve the effects of saving test equipment costs, saving verification cycles, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

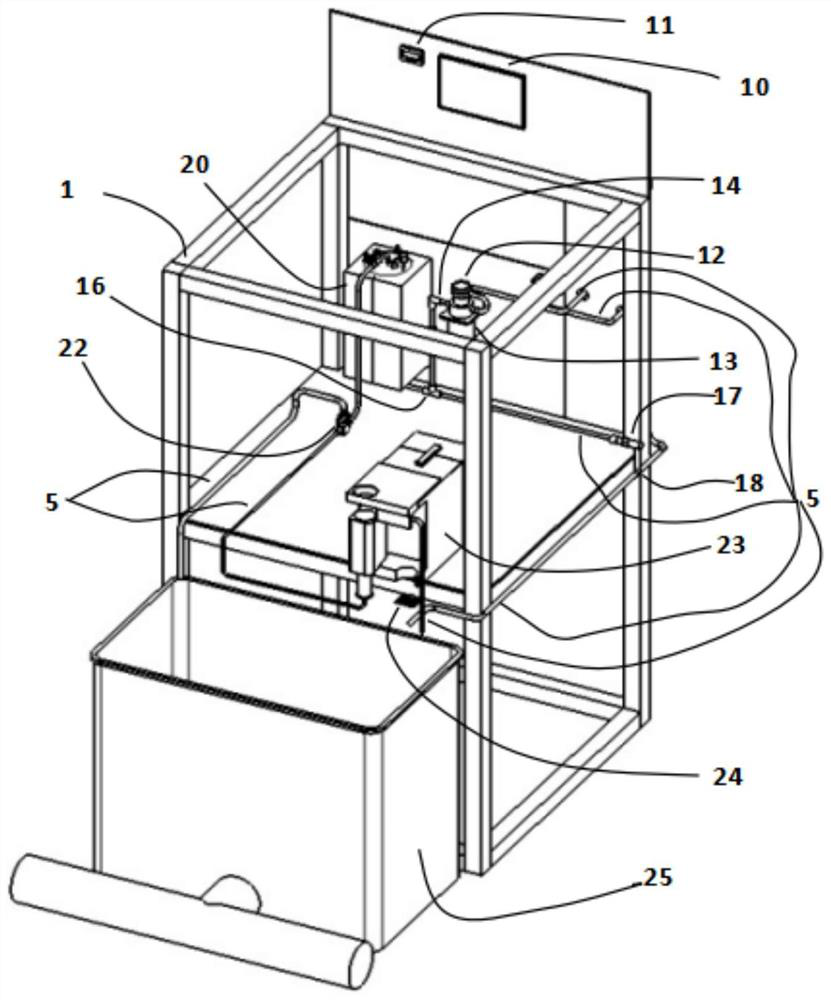

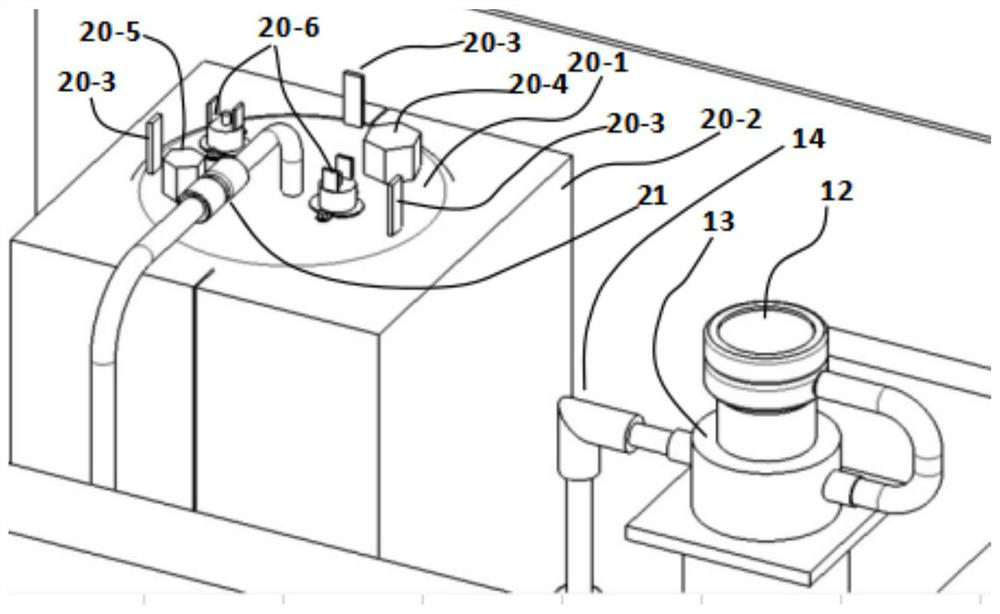

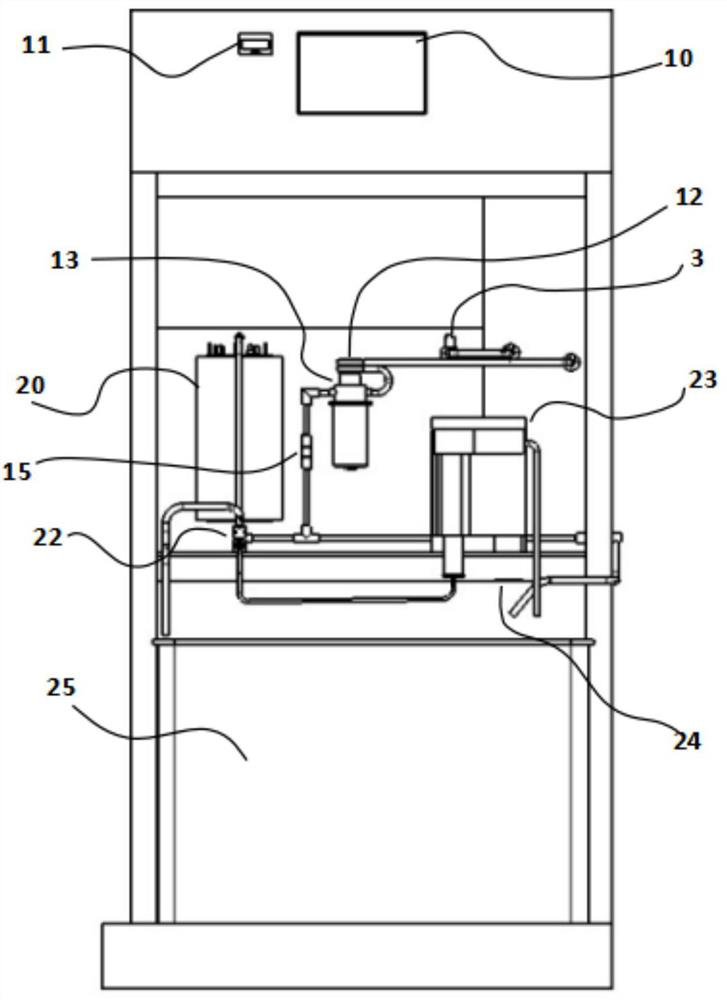

[0044] Such as Figure 1-5As shown, a brewer test device includes a main body support 1, a power supply module, a control module, a waterway module, a display module, a monitoring module, and a water boiling module. The main body support is provided with a display module, and the display module includes a touch A display screen 10, a voltage counter 11 and a power board 9, a water boiling module 20 is arranged below the display module, and the water boiling module 20 is connected to the water pipe 5 through a second L-shaped joint 19 below the water boiling module. 20 is connected to a brewing solenoid valve 22 through a straight-through joint 21, and the brewing solenoid valve 22 is connected to the waste bucket and the brewer 23 through a water pipe, and a water leakage sensor 24 is installed below the brewer. Connect the flow meter 12, the gear pump 13 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com