Box-type hangar

A hangar and box-type technology, applied in the field of construction engineering, can solve the problems of increasing construction costs, increasing the height of the roof section and large span requirements, and the effect is not obvious, so as to improve the seismic performance, enhance the structural rigidity and stability, reduce the height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present application will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

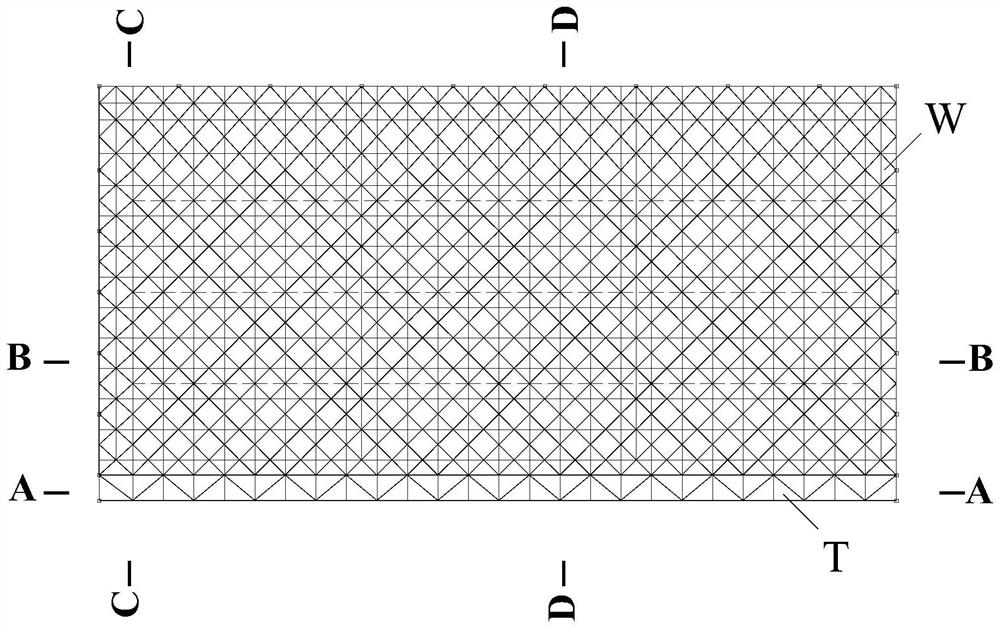

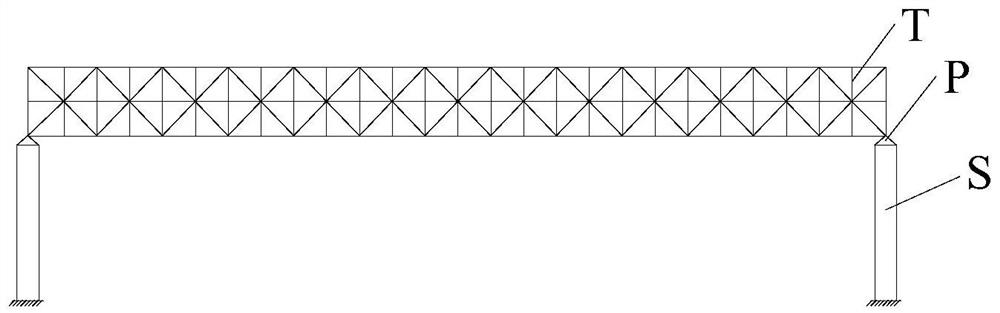

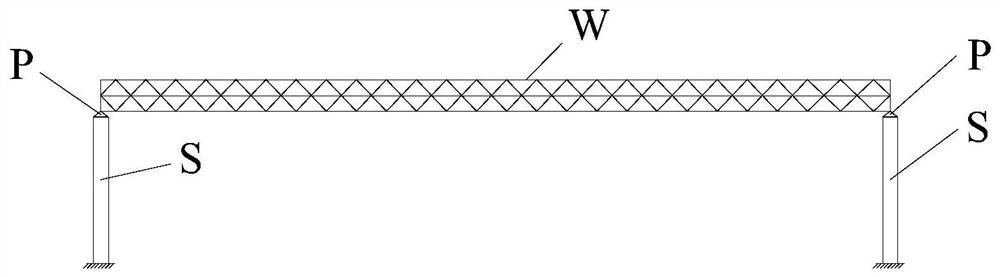

[0039] The present application provides a hangar, wherein the hangar includes a roof structure 10 and a support structure 20, and the roof structure 10 is rigidly connected to the support structure 20 as a whole, so that the roof structure 10 is connected to the support structure 20. The structure 20 forms a folded plate, and the support structure 20 supports both sides of the roof structure 10 in the length direction and one side of the roof structure 10 in the width direction, so that the hangar forms a box-type structure.

[0040] The roof structure 10 is just connected to the support structure 20, so that the roof structure 10 and the support structure 20 form a folded plate, so that the support structure 20 can be used to effectively reduce the internal force peak of the roof structure and reduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com