Method for regulating internal force of overhanging steel structure root member

A technology for steel structures and components, applied in special structures, building components, etc., can solve problems such as stress concentration, achieve the effect of reducing the peak value of internal force, reducing internal force, and increasing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0044] Take a central multi-storey cantilevered steel structure as an example:

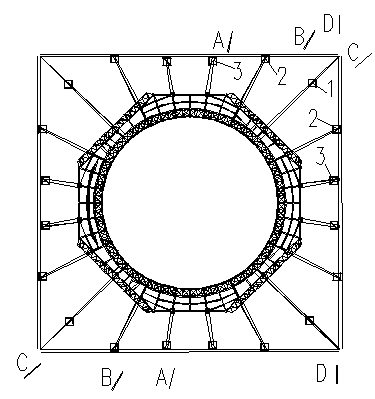

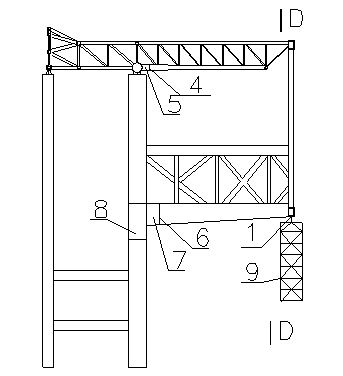

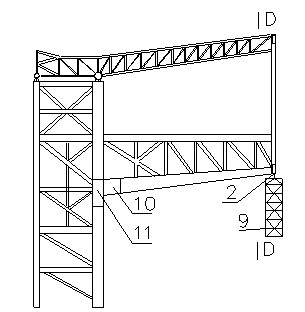

[0045] (1) The engineering example involved in the present invention has 3 types of cantilevered trusses with a total of 20 trusses, including 8 trusses in total for truss A, 8 trusses in total for truss B, and 4 trusses in total for truss C. Each truss cantilever has different lengths and vertical The load-bearing stiffness is different. Truss A has the highest stiffness and shares the most internal force. The stress at the bottom chord root of the cantilever truss cannot meet the design requirements only by the conventional method of increasing the section. The rods 5 and 7 in the truss A are selected as the post-installed rods of the present invention.

[0046] (2) Carry out construction simulation analysis on engineering examples, temporary support unloading devices 1, 2, and 3 are unloaded year-on-year, and the unloading is carried out in 4 steps.

[0047] (3) The installation timing of memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com