Solar cell packaging body and use method thereof

A solar cell and solar encapsulation technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of poor splicing flatness of solar panels, low splicing efficiency, inability to adjust the inclination angle of solar encapsulation panels, etc., so as to improve lighting efficiency and lighting. effect, high splicing efficiency, high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

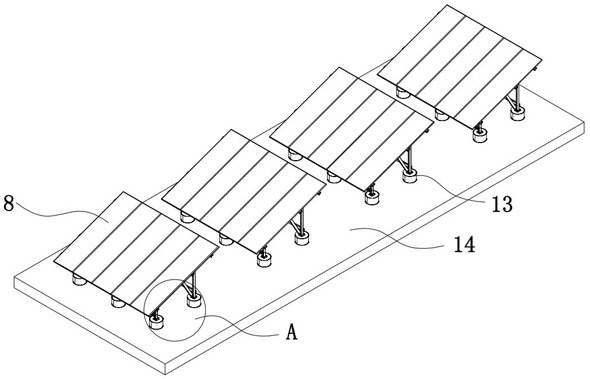

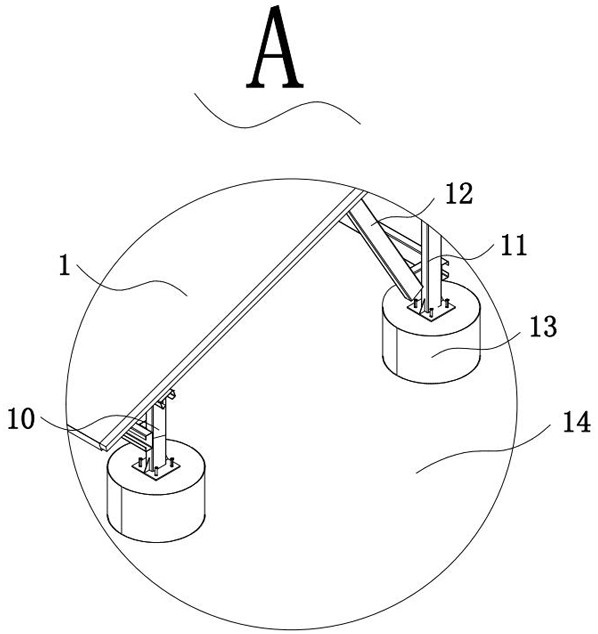

[0031] like Figure 1-4As shown, a solar cell package includes a solar panel 1, the solar panel 1 is in a single-plate mode, the solar panel 1 includes a battery slice 2, and an encapsulation layer 3 is provided on both sides of the battery slice 2, and the encapsulation layer 3 encapsulates the battery slice. The upper and lower ends of the 2 are encapsulated. The commonly used encapsulation layer 3 is an EVA film, which can encapsulate and protect the battery sheet 2 without causing damage to the performance of the battery sheet 2. The top of the top encapsulation layer 3 is provided with a cover plate 4. , the bottom of the bottom encapsulation layer 3 is provided with a back plate 5, the material of the cover plate 4 and the back plate 5 is tempered glass, the shape, volume and light transmission efficiency of the cover plate 4 and the back plate 5 are the same, and the cover plate 4 is in the vertical direction. The projection on it is staggered from the back plate 5, so ...

no. 2 example

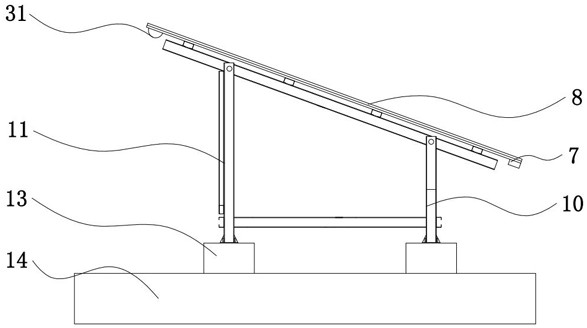

[0039] like Figure 5-8 As can be seen from the first embodiment, when the solar cell package is actually used, multiple groups of solar panels 1 are spliced together. Since both the cover plate 4 and the back plate 5 are in rigid pressing contact with the adjacent solar panels 1, Therefore, when a certain solar panel 1 is processed unevenly, it will affect the flatness of the overall solar encapsulation panel 8; at the same time, because there is no sunlight at night, power generation cannot be performed, so it can only work during the day, and the power generation time is short. The power generation efficiency is low and is easily affected by the environment, and with the continuous movement of the sun during the day, the lighting efficiency of the solar encapsulation panel 8 also changes accordingly; especially at night, the power generation efficiency of the wind power generation components 27 corresponding to different wind power is also different. The above problems im...

no. 3 example

[0062] A method of using a solar cell package for operating a solar cell package, comprising the following steps:

[0063] S1. An encapsulation layer 3 is arranged on the outer surface of the battery sheet 2, a cover plate 4 is arranged on the top of the top encapsulation layer 3, and a back plate 5 is arranged at the bottom of the bottom encapsulation layer 3. The cover plate 4 and the back plate 5 are arranged alternately, and the battery A side adhesive layer 6 is provided on the peripheral side of the sheet 2;

[0064] S2. When multiple sets of solar panels 1 are spliced to form a solar encapsulation panel 8, the airbag 17 is squeezed to drive the piston block 19 to match the communication pipe 16, the air inlet hole 15 is connected with the air outlet hole 22, and the solar energy packaging panel is 8 weeks. The airbag 17 on the side is not squeezed, the air inlet hole 15 and the air outlet hole 22 are staggered, and the fixing hoop 9 is clamped with the side surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com