Equipment for full-automatic mechanical sampling and rapid online ash measurement

A mechanical sampling and fully automatic technology, applied in the field of sampling ash measurement, can solve the problems that the speed cannot meet the actual needs, affect the accuracy of ash measurement results, and detection lag, etc., to improve measurement accuracy and accuracy, increase speed, Reduce the effect of the detection path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional transformations made by those of ordinary skill in the art based on these embodiments are all included in the protection scope of the present invention.

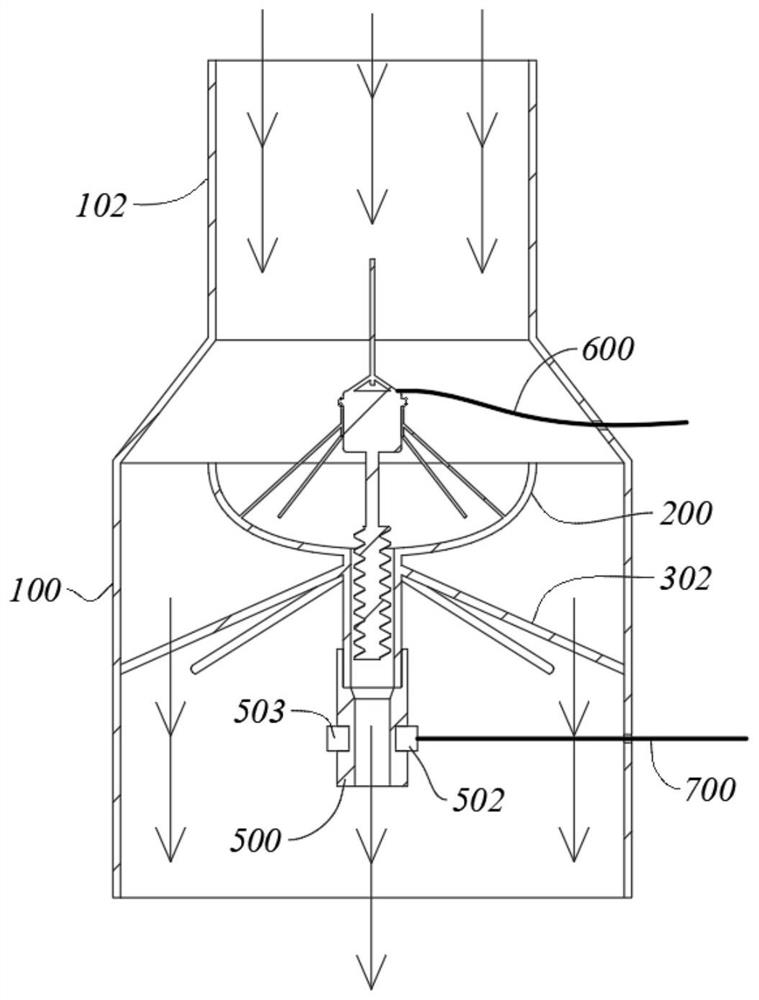

[0030] An embodiment of the present invention discloses a device for automatic mechanical sampling and rapid on-line ash measurement, including a chute 100 , a collection frame 200 , a guide tube 300 and a measurement tube 500 .

[0031] ginseng Figure 1 to Figure 3 As shown, the upper end of the chute 100 is provided with a connecting pipe 102, the inner diameter of the connecting pipe 102 is smaller than the inner diameter of the chute 100, and the inner diameter of the connecting pipe 102 is the same as the maximum inner diameter of the collection frame 200, which can largely ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com