Air cannon heavy piston quick reset system and method for aircraft high-speed impact test

A high-speed impact and air cannon technology, applied in the field of air cannon heavy piston quick reset system, can solve the problems of air cannon safety, waste of manpower and material resources, low efficiency, etc., to improve the effect of high-speed impact test of aircraft and reduce workload , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

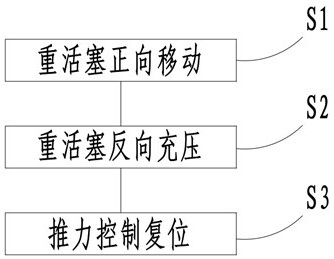

Method used

Image

Examples

Embodiment 1

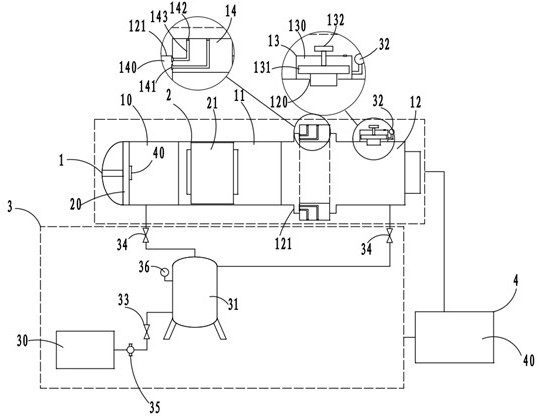

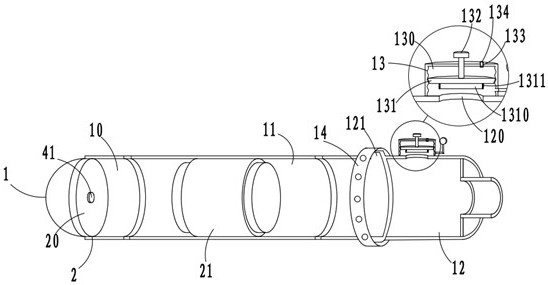

[0038] like figure 1 , 2 , 3, the air cannon heavy piston quick reset system for the aircraft high-speed impact test includes a compression tube 1, a piston assembly 2, an air pressure detection assembly 3 connected to the compression tube 1, and an electrical monitoring assembly 4. The inside of the compression tube 1 is from left to The right is the energy storage cavity 10, the sliding cavity 11 and the energy releasing cavity 12 in sequence, and the energy storage cavity 10, the sliding cavity 11 and the energy releasing cavity 12 are connected with each other;

[0039] like Image 6 As shown, the piston assembly 2 includes a balance piston 20 which is arranged in the energy storage chamber 10 and acts as a seal, and a heavy piston 21 that can slide left and right in the energy storage chamber 10, the sliding chamber 11 and the energy releasing chamber 12; the heavy piston 21 includes The support body 210 is provided with an extrusion notch 2100 on the outer wall, and th...

Embodiment 2

[0047] This embodiment differs from Embodiment 1 in that:

[0048] like Image 6 As shown, two locking blocks 2101 are symmetrically distributed at the opening of the extrusion recess 2100, and the outer wall of the elastic extrusion block 2110 is provided with a card slot 2111 corresponding to the locking blocks 2101 one-to-one. The locking blocks 2101 It can be snapped into the corresponding card slot 2111 .

Embodiment 3

[0050] This embodiment differs from Embodiment 2 in that:

[0051] like figure 2 , 3 , 4, the side wall of the energy release cavity 12 is provided with an expansion section 121 with an increased radius, and the expansion section 121 is provided with a jet pressure release ring 14, the jet pressure release ring 14 is a hollow cylindrical structure, and the jet pressure release ring 14 The radius of the inner circle is equal to the radius of the energy releasing cavity 12 , and the jet pressure releasing ring 14 is provided with an interface 140 between the side close to the sliding cavity 11 and the expansion section 121 . There are 6 inner energy releasing holes 141, and the outer circular side wall of the jet pressure releasing ring 14 is provided with 6 outer energy releasing holes 142 corresponding to the inner energy releasing holes 141 one-to-one, and the outer energy releasing hole 142 and the inner energy releasing hole 141 are connected with each other. are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com