Freezing chamber and refrigerator with same

A freezer and freezer technology, which is applied to household refrigerators, coolers, household appliances, etc., can solve the problems of uneven temperature in the freezer, increased energy consumption, and reduced storage space, so as to achieve enhanced process operation feasibility, The effect of reducing storage and manufacturing costs and increasing the rate of blister molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

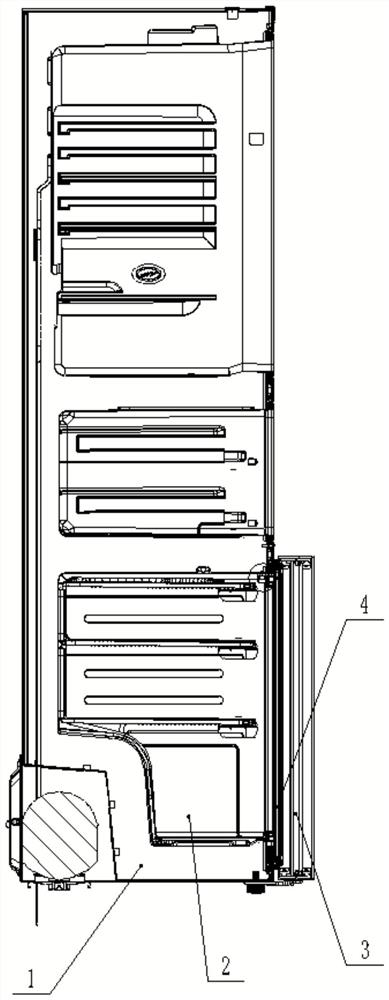

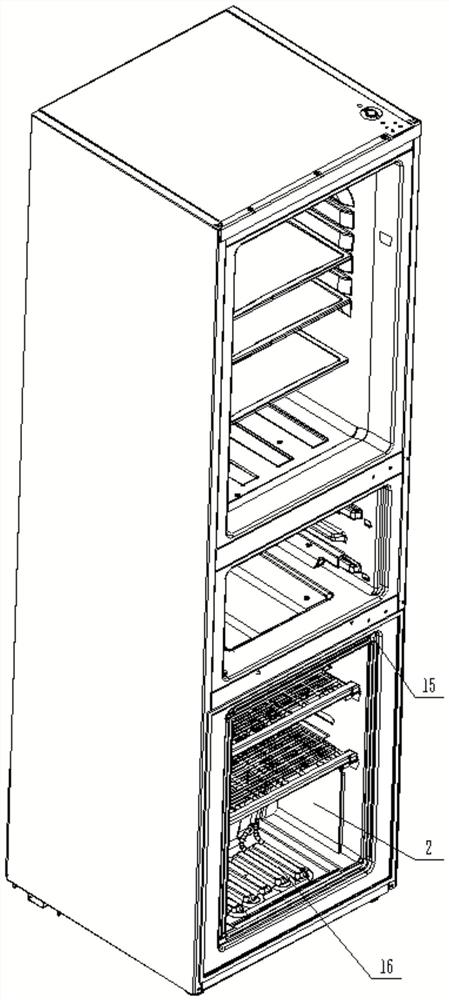

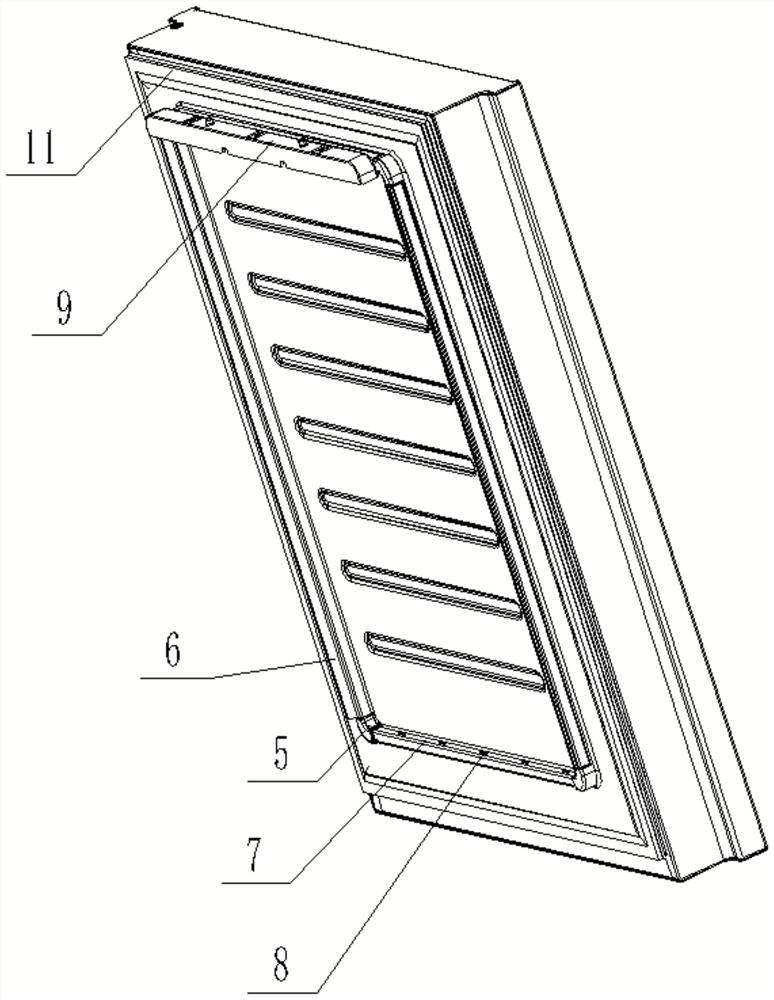

[0029] like Figure 1-5 As shown, a freezer includes a freezer body 1, a freezer door body 3 hinged on the freezer box body 1, a freezer box inner bladder 2 inside the freezer box body, a freezer door bladder 4 inside the freezer door body, and the freezer door There are an outer door seal 11 and an inner door seal at the upper edge of the bladder, the inner door seal includes a hard main body 12, a soft blade 13 on one side of the hard main body, a mounting groove 10 on the periphery of the freezer door, and an outer door. The seal 11 is embedded in the re-installation slot 10, the outer door seal has a magnetic strip, and the freezer box body has a multi-layer refrigeration pipeline 16, and the medium flow direction between the two adjacent layers of refrigeration pipelines is opposite; Optimize the cooling medium pipeline to improve the cooling effect. There is a circle of protruding ribs 5 on the inner side wall of the freezer door corresponding to the inner door seal. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com