Air leakage silencing method and device for air compressor

A technology of air compressor and muffler, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problem of high noise of air compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

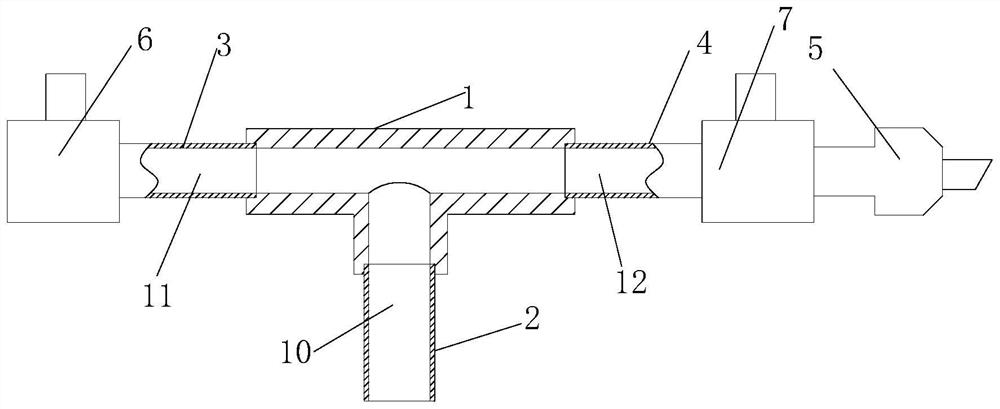

[0033] like figure 1 An air compressor exhaust muffler device shown, the device includes a three-way joint 1, a general communication pipe 2, a first branch pipe 3, a second branch pipe 4, a muffler 5, a first valve 6 and a second valve 7 ,

[0034] The first branch pipe 3, the second branch pipe 4 and the general communication pipe 2 are all communicated through the three-way joint 1, and the first valve 6 and the second valve 7 are respectively arranged on the first branch pipe 3 and the second branch pipe 4, and the noise is eliminated. The device 5 is installed on the second branch pipe 4, the first valve 6 and the second valve 7 can be valves in the prior art, and the general communication pipe 2 is communicated with the air inlet of the air compressor;

[0035] The muffler 5 is the muffler 5 installed on the tail pipe of the automobile or the tail pipe of the motorcycle in the prior art;

[0036] The general communication pipe 2 has a general passage 10 , the first bra...

Embodiment 2

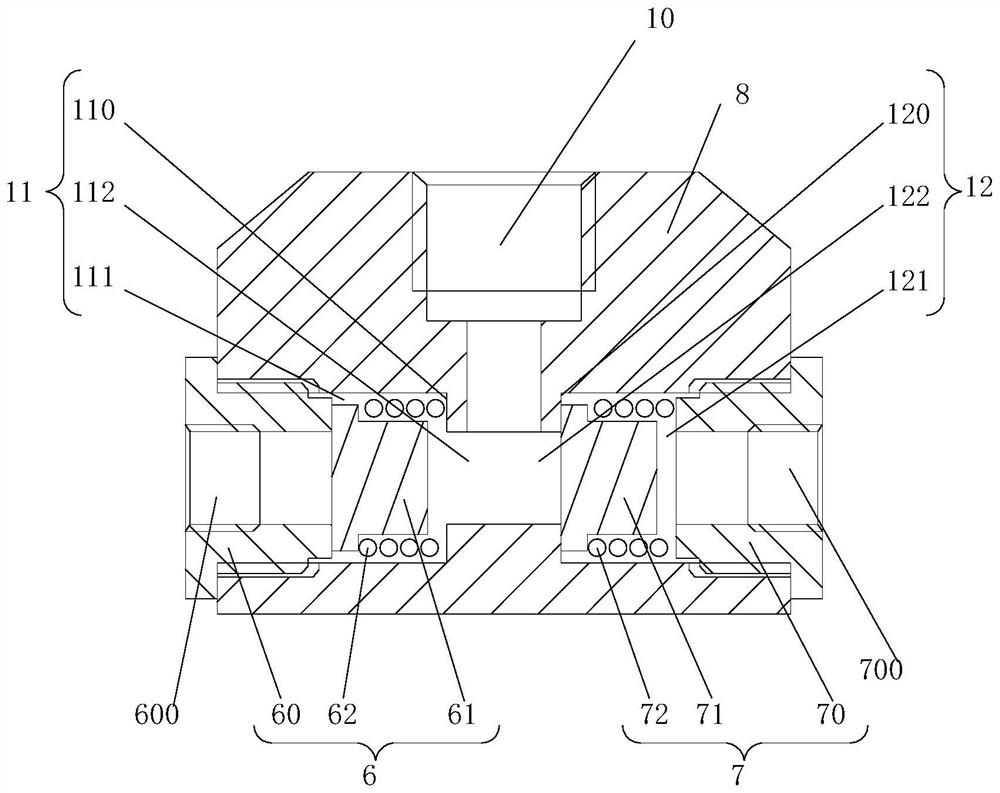

[0041] like figure 2As shown, the difference between this embodiment and the above-mentioned embodiment is that the main body 8 is included, and the total passage 10, the air inlet passage 11 and the air outlet passage 12 of the device are all opened on the main body 8, and the first valve 6 and the second The valves 7 are all integrated on the body 8, so that the device has a simple structure and a small footprint, and the general passage 10 communicates with the air inlet of the air compressor;

[0042] Specifically, the intake passage 11 has an intake stepped ring 110, and the intake stepped ring 110 divides the intake passage 11 into a first intake passage 111 and a second intake passage 112, and the first intake passage 111 and the second intake passage 112. The intake passages 112 are coaxial and have different apertures. The inner diameter of the first intake passage 111 is larger than the inner diameter of the second intake passage 112 . The first intake passage 111 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com