Device and method for brushing paint by using magnetic paint

A technology of magnetic paint and brushing, applied in the field of paint, to achieve the effect of enhancing strength and colloidal rate, simple implementation and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

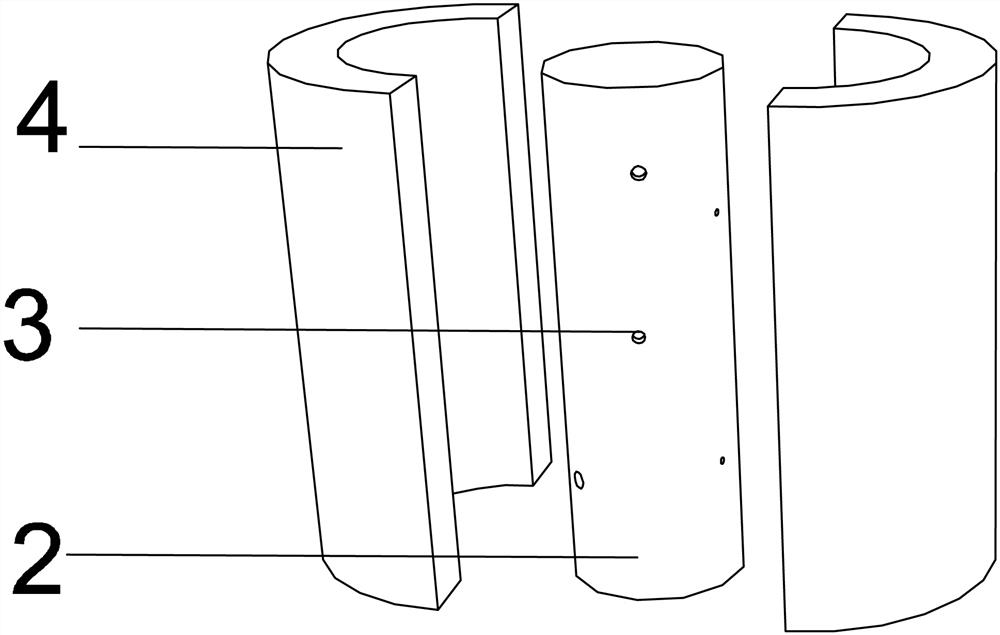

[0065] see Figure 1-6 , a device for painting with magnetic paint, which includes a solid cylindrical object painting system for painting a solid cylindrical object 2 to be painted, the solid cylindrical object painting system includes an adjustable clamp 4, an adjustable The clamp 4 is used to hold the solid cylindrical object 2 to be painted; when painting, the solid cylindrical object 2 to be painted is immersed as a whole into the interior of the magnetic paint carrier 1, and a magnet block 18 is arranged above it. By using the above-mentioned solid cylindrical object painting system, the painting of the solid cylindrical object 2 to be painted can be fully realized, thereby ensuring the bonding reliability and painting effect after painting.

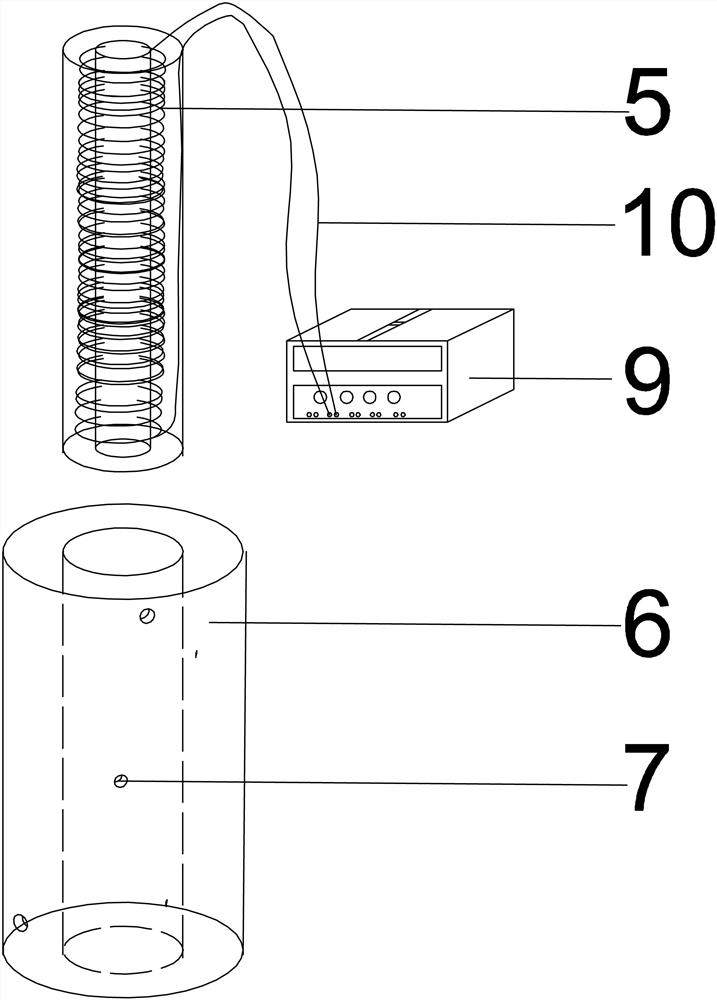

[0066] Further, it includes a hollow cylindrical object painting system for painting the hollow cylindrical object 6 to be painted, the hollow cylindrical object painting system includes a support arm 8, and an electromagnetic coil...

Embodiment 2

[0076] A method for painting a solid cylindrical member by using a magnetic paint painting device, comprising the following steps:

[0077] Step1.1, prepare materials: prepare a magnetic paint carrier 1, a solid cylindrical object to be brushed 2, an adjustable clamp 4 and a magnet block 18.

[0078] Step1.2, add magnetic paint to the magnetic paint carrier 1;

[0079] Step1.3, adjust the angle of the adjustable clamp 4, so that the solid cylindrical object 2 to be brushed can just be clamped by the adjustable clamp 4;

[0080] Step1.4, move the solid cylindrical object 2 to be brushed that has been fixed with the adjustable clamp 4 into the magnetic paint carrier 1, and let the magnetic paint immerse the solid cylindrical object to be brushed 2, so that the magnetic paint and the solid cylindrical object to be brushed can be Object 2 is in large area contact;

[0081] Step1.5, place the magnet block 18 above the adjustable clamp 4 for fixing the solid cylindrical object to ...

Embodiment 3

[0083] A method for painting a hollow cylindrical member by using a magnetic paint painting device, comprising the following steps:

[0084] Step2.1, prepare materials: electromagnetic coil 5, hollow cylindrical object to be brushed 6, support arm 8, DC power supply 9, wire 10 and magnetic paint carrier 1;

[0085] Step2.2, the electromagnetic coil 5 is connected with the DC power supply 9 through the wire 10, so that the electromagnetic coil 5 generates a magnetic force;

[0086] Step2.3, then pass the electromagnetic coil 5 through the hollow cylindrical object 6 to be brushed, and the hollow cylindrical object 6 to be brushed can rotate freely;

[0087] Step2.4, link the two support arms 8 and the electromagnetic coil 5 by nesting;

[0088] Step2.5, let the magnetic paint immerse the hollow cylindrical object to be brushed 6, let the magnetic paint contact the hollow cylindrical object to be brushed 6 in a large area, and then provide magnetic force, so that the magnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com