Reinforcing component for fabricated wall

A prefabricated, wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of weak strength, single structure, unable to meet the needs of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be described in further detail with reference to the accompanying drawings. The accompanying drawings are simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, and thus only show the structures related to the present invention.

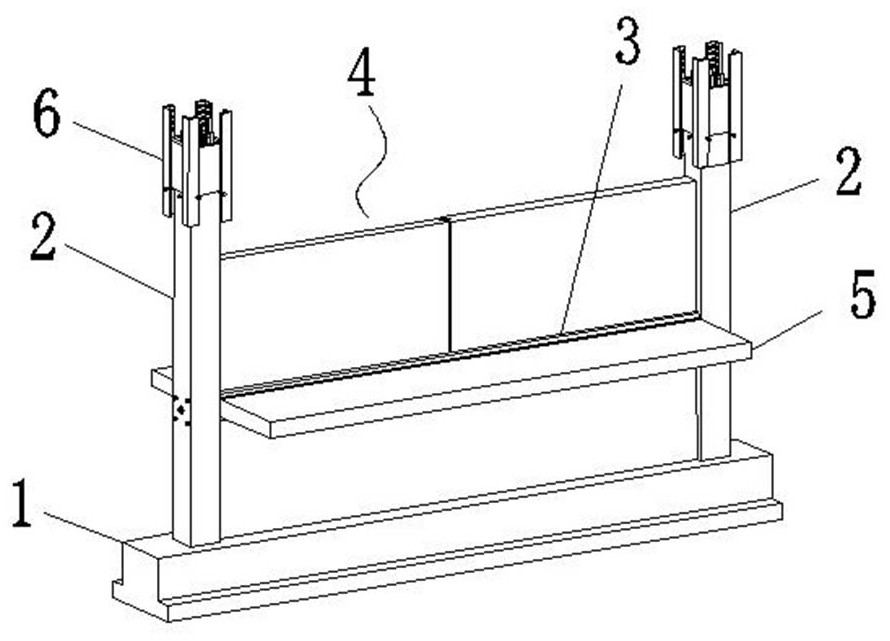

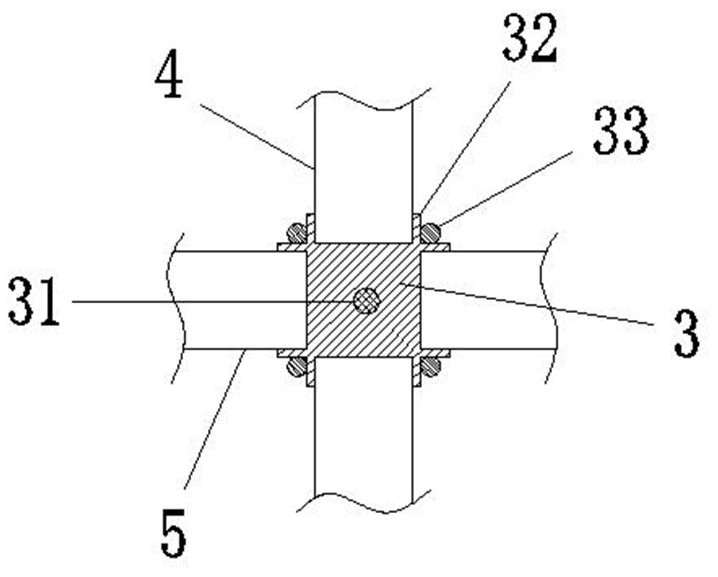

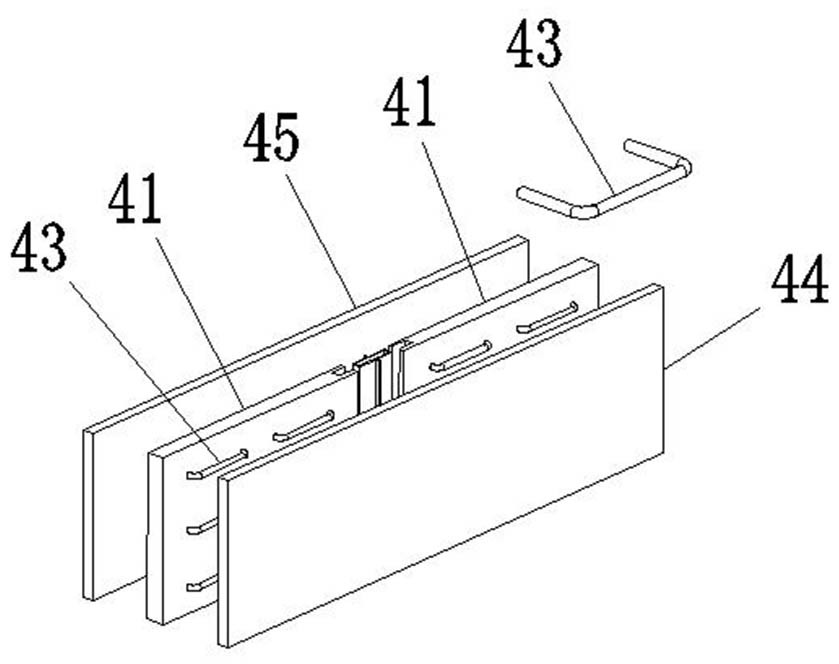

[0025] Please refer to figure 1 , the technical scheme of the present invention is: a reinforcement component for an assembled wall body, comprising a base 1 and two vertical beams 2 fixed on the base 1, a beam 3 is arranged between the two vertical beams 2, and the said The beam 3 is rectangular and is provided with a limit angle steel 32 on the four horizontal edges. The upper and lower sides of the beam 3 are provided with a wall 4 between the two limit angle steels 32, and the surface of the base 1 is provided with a fixed The groove, the vertical beam 2 and the wall 4 below are arranged in the fixing groove on the surface of the base 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com