Surface treatment device for alloy material

A surface treatment device and alloy material technology, which is applied in the field of alloy material surface treatment devices, can solve the problems of uneven distribution of projectiles, inability to projectile, and uncleaning of the bottom of the workpiece, and achieve the goal of simplifying the overall structure, simplifying the structure, and shortening the stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

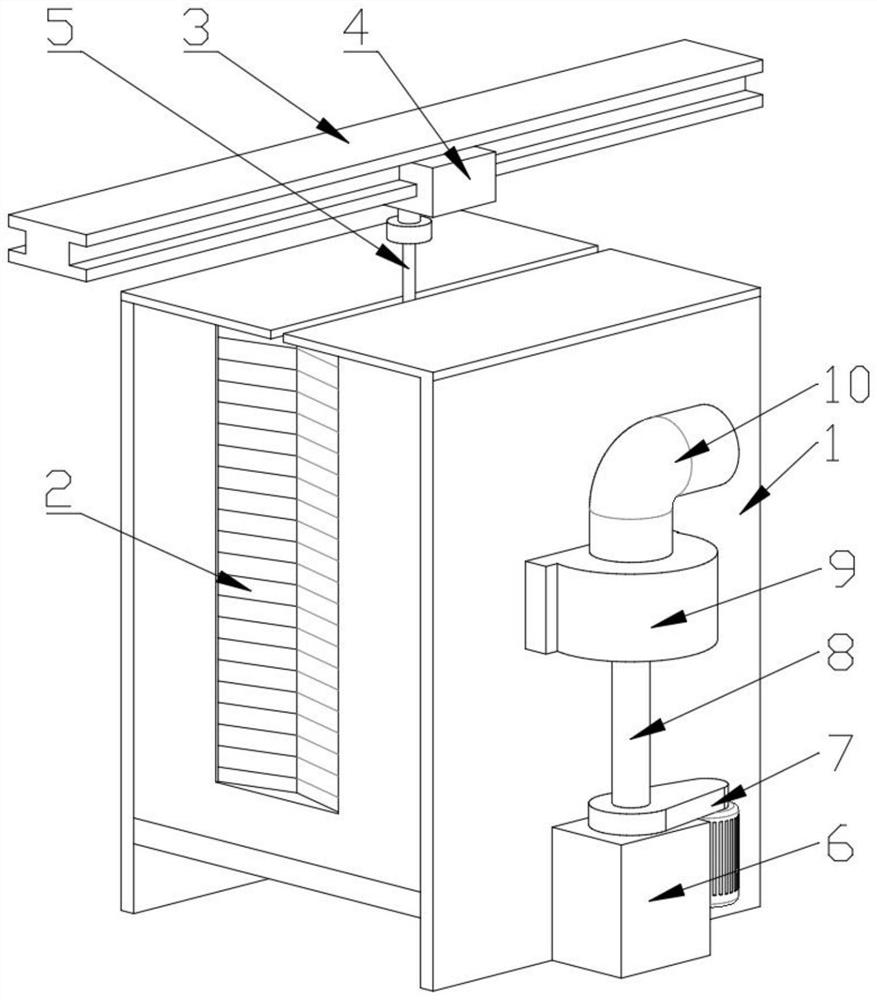

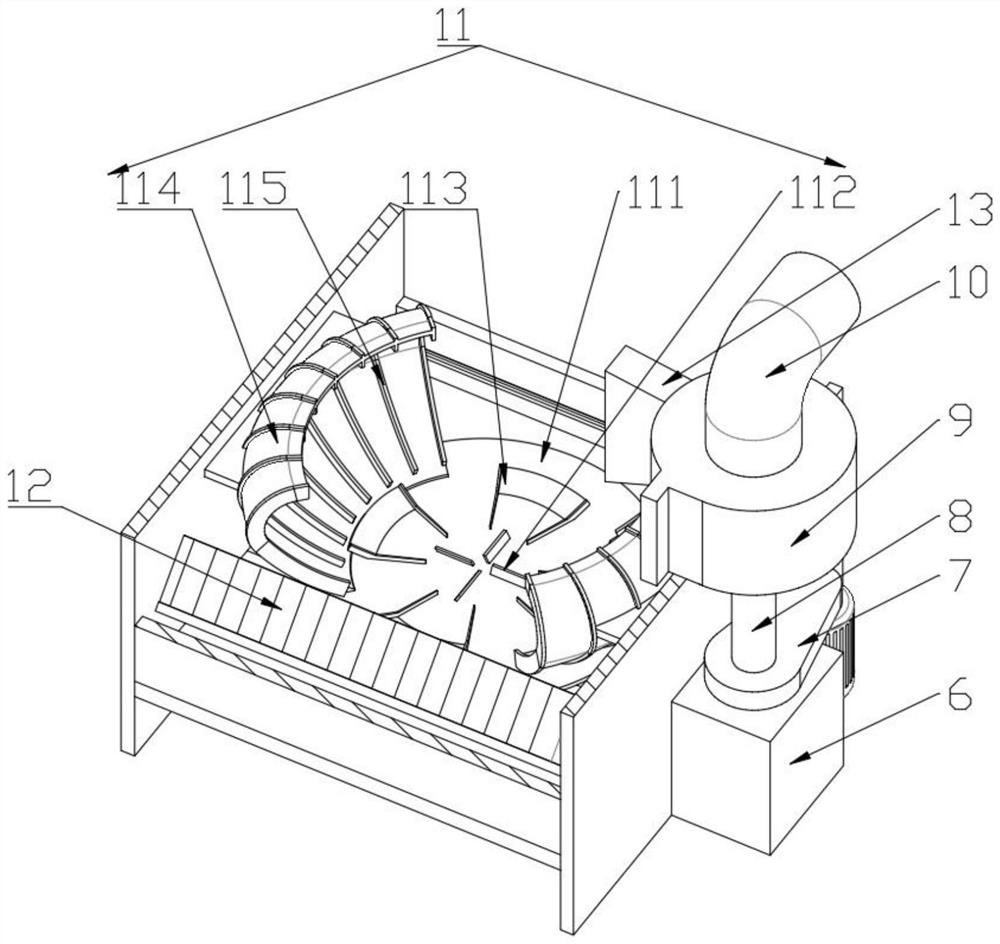

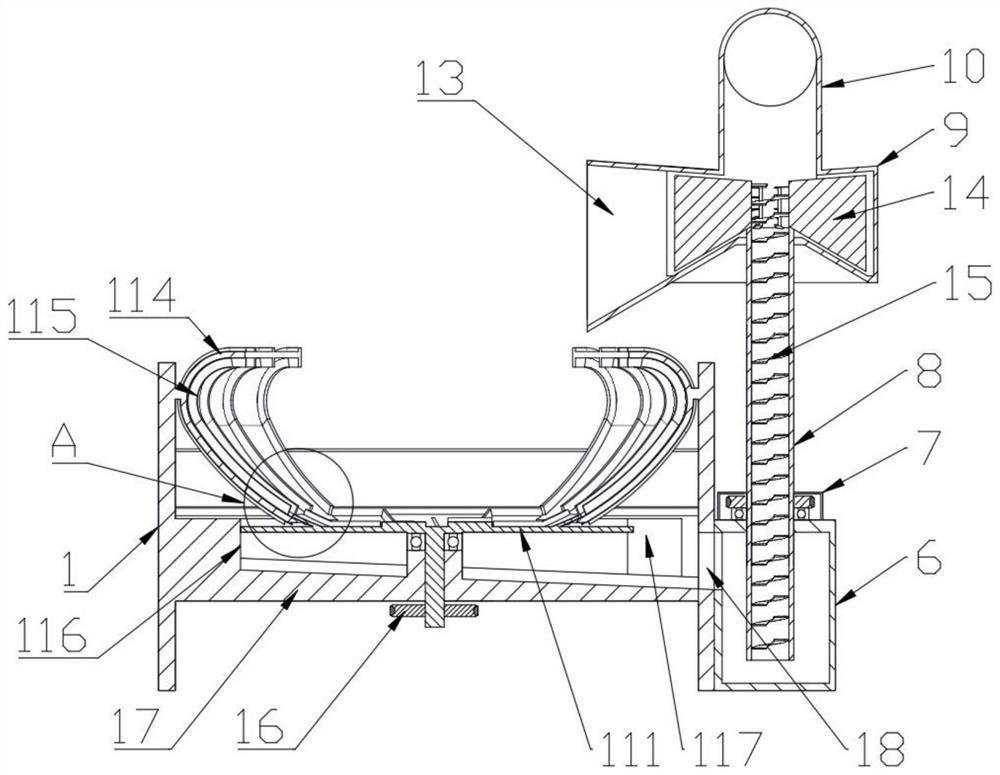

[0039] see Figures 1 to 3 , in this embodiment, a device for surface treatment of alloy materials is provided, including: a chassis 1, a conveying track 3, a conveyor 4, a suspension system 5 and a shot blasting system; the conveyor 4 is movably installed in the The conveying track 3 is used for conveying the workpiece into the case 1, and a suspension system 5 for suspending the workpiece is installed at the bottom; the shot blasting system is installed in the case 1 and is used for projecting projectiles to the workpiece. , the shot blasting system consists of a shot blasting device A9 for projecting projectiles to the side of the workpiece and a shot blasting device B11 for projecting projectiles to the bottom of the workpiece;

[0040] The side wall of the case 1 is provided with a workpiece inlet and a workpiece outlet on the moving path of the conveying track 3, and both the workpiece inlet and the workpiece outlet are provided with baffles 2A for blocking projectiles, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com