Auxiliary manual silicon rod wiping system

A silicon rod and manual technology, applied in the field of auxiliary manual wiping silicon rod system, can solve the problems of high labor intensity, silicon rod damage, slow efficiency, etc., to achieve the effect of maximizing efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

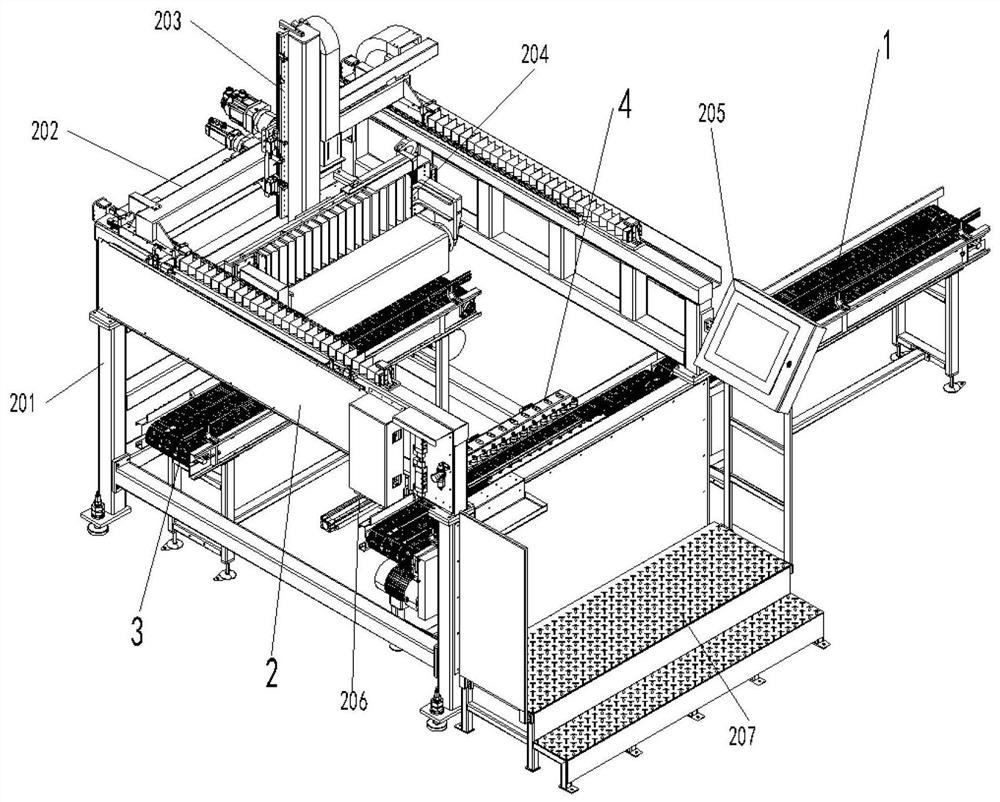

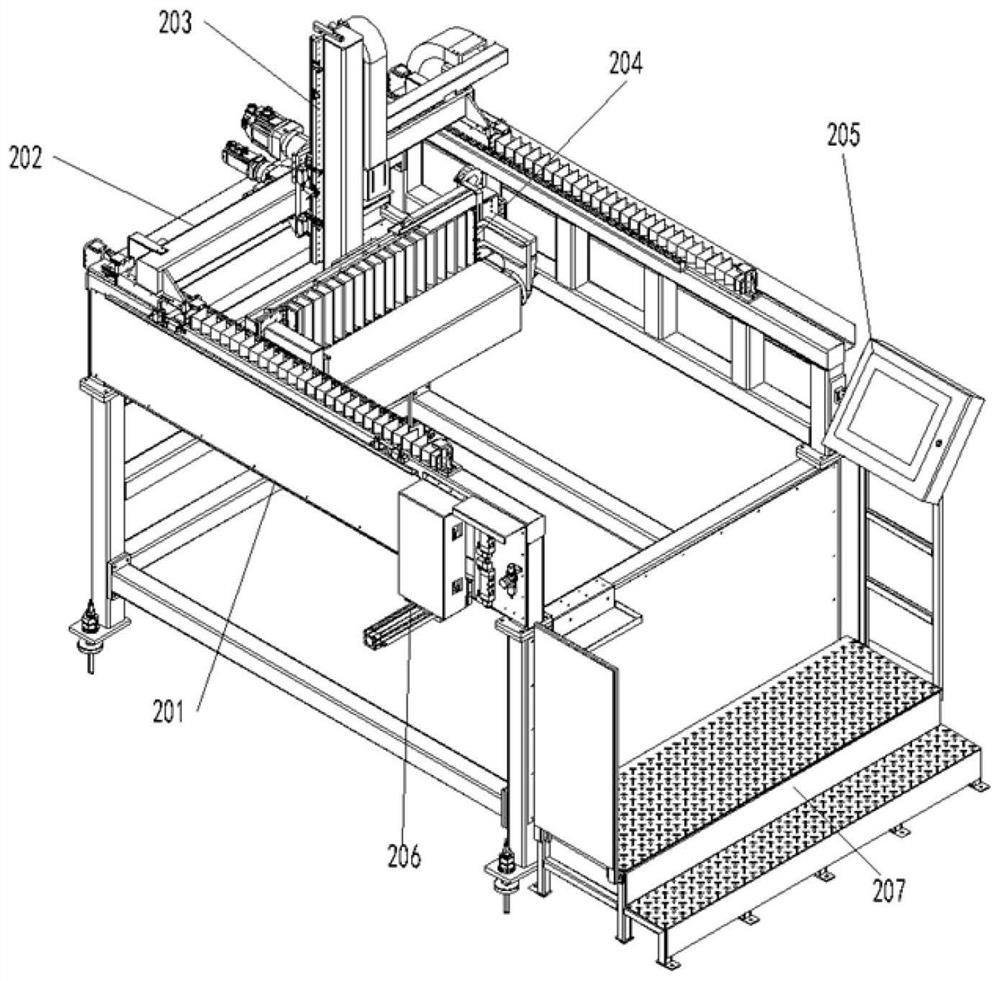

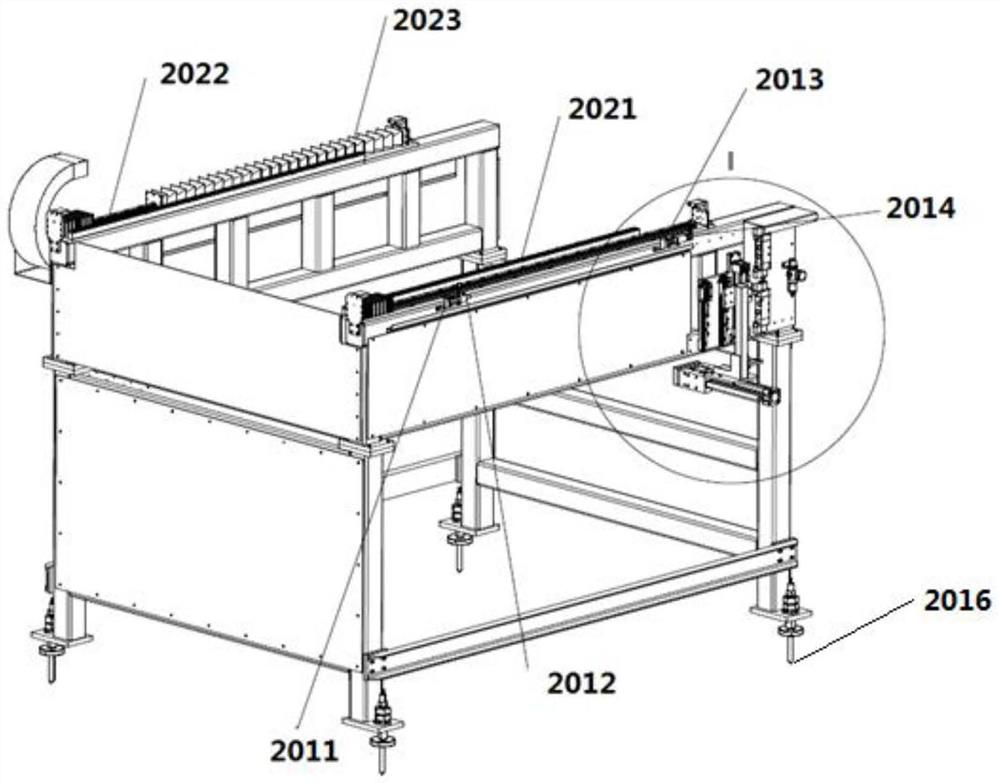

[0047] An auxiliary manual wiping silicon rod system, such as Figure 1-Figure 16 As shown, it includes a wiping machine 2, an unloading conveyor line 3, a feeding conveyor line 1, and a jacking and centering mechanism 4; the wiping machine 2 includes a wiping frame body 201, the unloading conveyor line 3, the feeding conveyor Lines 1 are respectively arranged on both sides below the wiping frame body 201, and the feeding and conveying line 1 is arranged at the middle position of the jacking and centering mechanism 4; the wiping frame body 201 is provided with X axis 202, Z axis 203, The wiping machine manipulator 204 , the control screen 205 , and the side push mechanism 206 ; the side push mechanism 206 is arranged on the side wall of the wiping frame body 201 , and the control screen 205 is arranged at one end of the wiping frame body 201 .

[0048] The auxiliary manual wiping silicon rod system is also equipped with an auxiliary platform 207, and the auxiliary platform 207...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com