Mercury, sulfur and carbon synergistic and integrated removal dust removal system

A dust removal system, sulfur carbon technology, applied in the fields of sulfur compounds, solid separation, inorganic chemistry, etc., can solve the problems of complex process, large area and high cost, and ensure the emission of particulate matter at the outlet, low cost and small area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

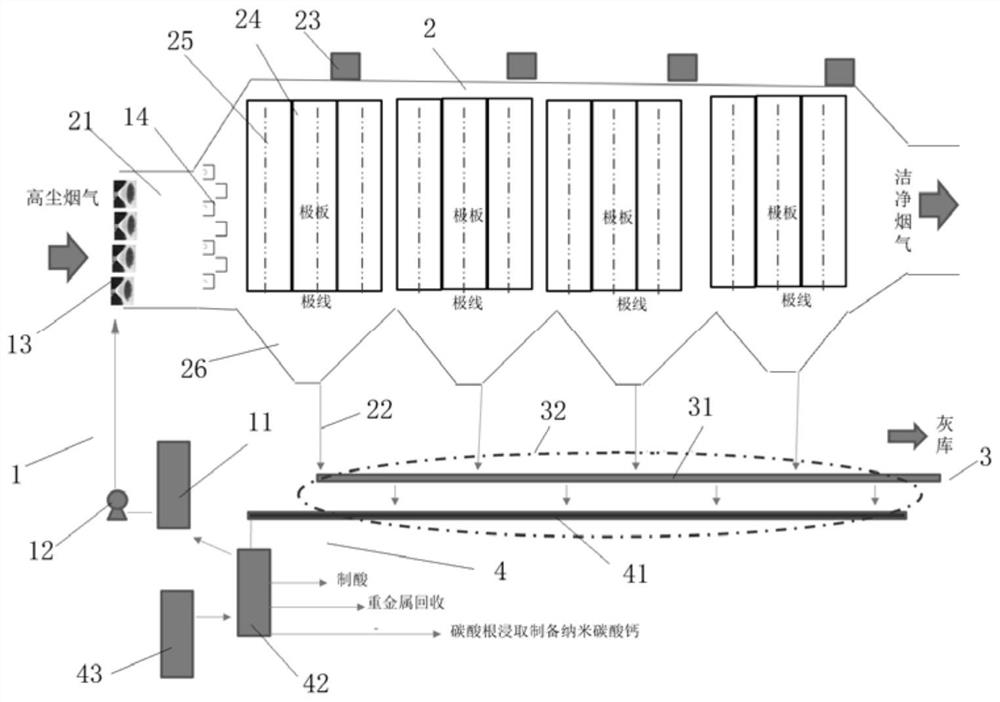

[0017] see figure 1 , the present invention is a dedusting system for the integrated removal of mercury, sulfur and carbon, including an absorbent injection system 1, a dust removal system 2, an ash conveying system 3 and a magnetic adsorbent recycling system 4. The absorbent injection system 1 is on the Several dry powder spray guns 13 are provided, and the dry powder spray guns 13 are installed in the inlet flue 21 of the dust removal system 2. The ash conveying system 3 includes an ash conveying mechanism 31 and a magnetic separation device 32 (not shown in the figure). The ash discharge port of the dust removal system 2 is connected to the inlet of the ash conveying mechanism 31, the magnetic separation device 32 is used to magnetically select the magnetic adsorbent in the fly ash conveyed by the ash conveying mechanism 31, and the outlet of the magnetic separation device 32 It is connected to the inlet of the magnetic adsorbent recycling system 4 , and the outlet of the m...

Embodiment 2

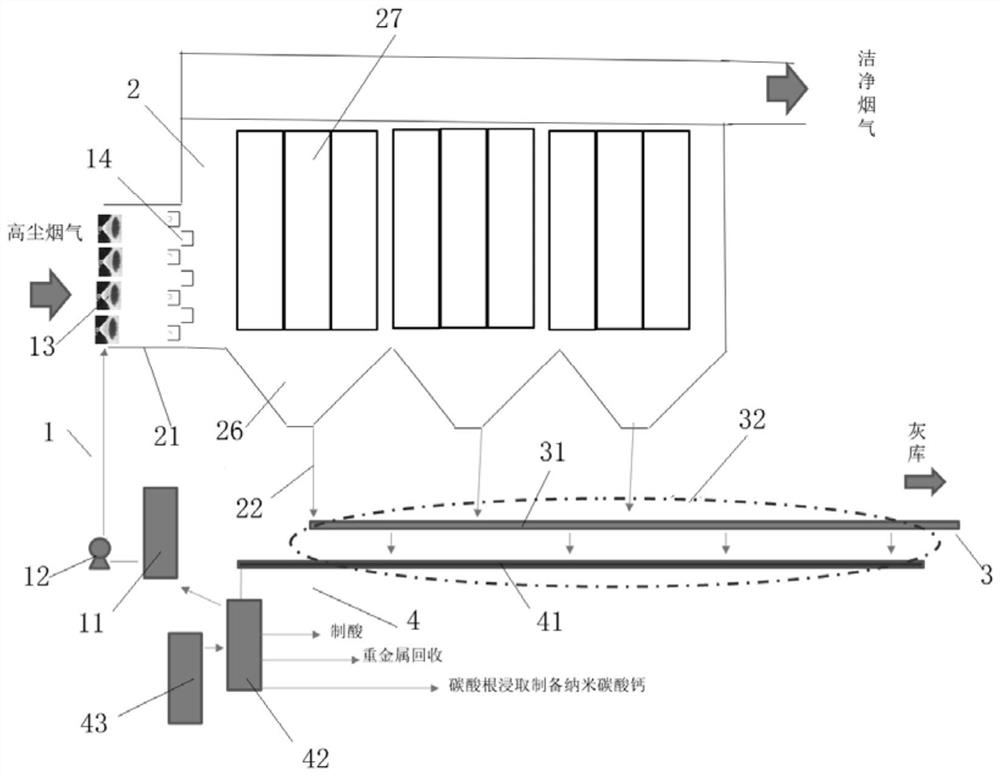

[0028] see figure 2 The difference between this embodiment and Embodiment 1 is that the dust collector is a bag type dust collector, including a body, a cage, a cloth bag 27, a top-level airflow uniform distribution, a backflushing system, an ash hopper 26, and the like.

[0029] The working process of the present invention:

[0030] Through the absorbent injection system 1, the magnetic mercury-sulfur-carbon adsorbent can be uniformly injected into the inlet flues 21 of all levels of electric fields. The adsorbent is fully mixed with the flue gas, and the adsorbent after absorbing pollutants is collected by the bag filter and collected in the ash hopper 26, and the adsorbent stays on the surface of the bag 27 for a long time, and the adsorption and removal effect is better than that of the electrostatic precipitator. Good; before the fly ash is transported to the ash warehouse via the ash conveying mechanism 31, the magnetic adsorbent mixed in the ash is magnetically separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com