Movable membrane bioreactor and sewage treatment system and method

A technology of membrane bioreactor and sewage treatment system, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Together, reduce membrane fouling and other issues, to achieve the effect of slowing down membrane fouling, improving efficiency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

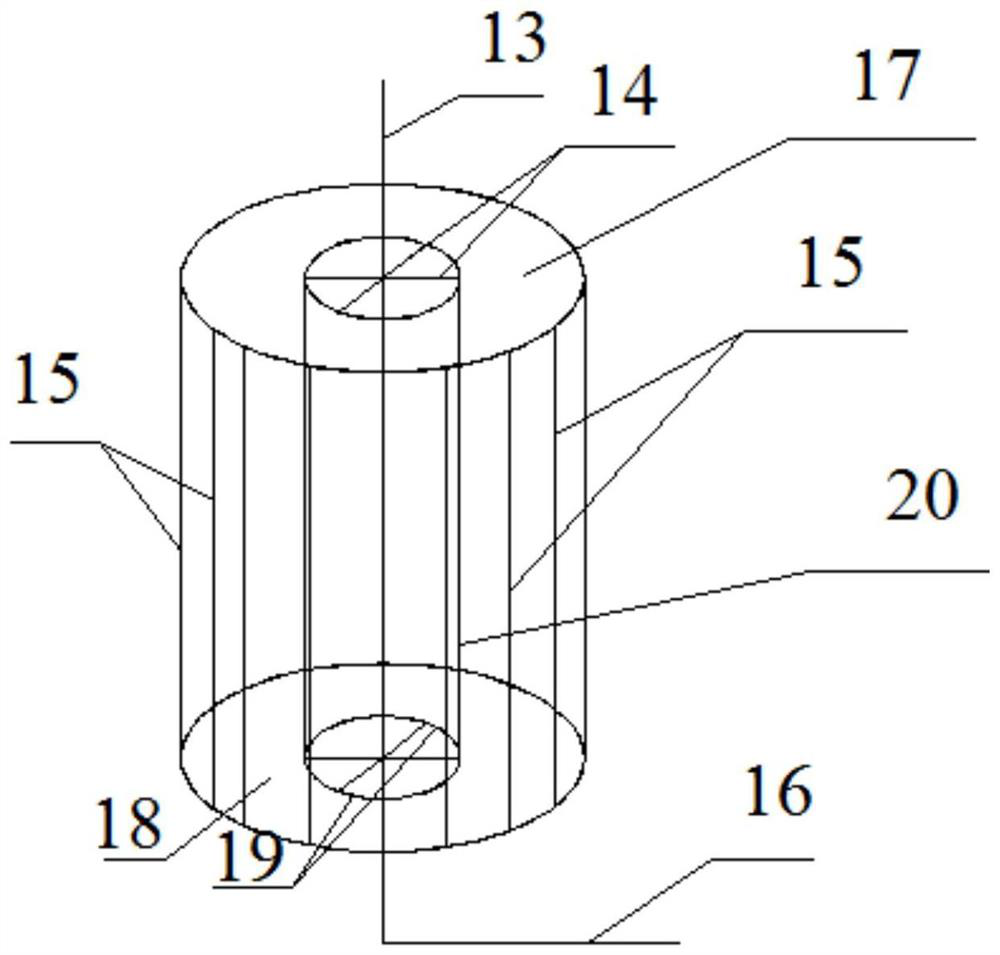

[0090] This embodiment provides a dynamic membrane bioreactor, the schematic diagram of which is as follows: figure 1 shown, from figure 1 It can be seen that the dynamic membrane bioreactor includes:

[0091] The upper end cap 17, the lower end cap 18, the hollow shaft 13 and several hollow fiber membrane filaments 15. The upper end cap 17 and the lower end cap 18 are of the same size as a circular box-type structure, and the upper end cap 17 and the lower end cap 18 are arranged between There are several support frames 20 for supporting and fixing the upper end cover 17 and the lower end cover 18; the bottom surface of the lower end cover 18 is provided with a water outlet;

[0092] The hollow shaft 13 is arranged between the upper end cover 17 and the lower end cover 18, and makes the upper end cover 17 and the lower end cover 18 communicate with each other at the center thereof;

[0093] A plurality of the hollow fiber membrane filaments 15 are vertically arranged betwee...

Embodiment 2

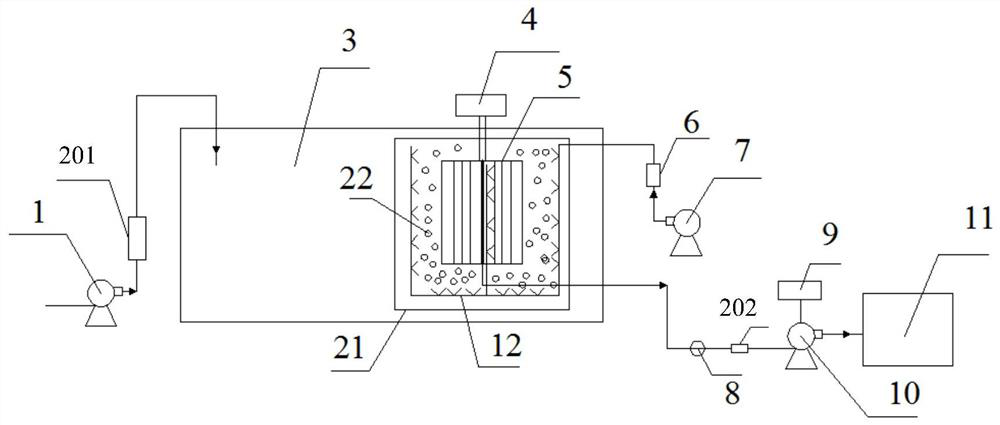

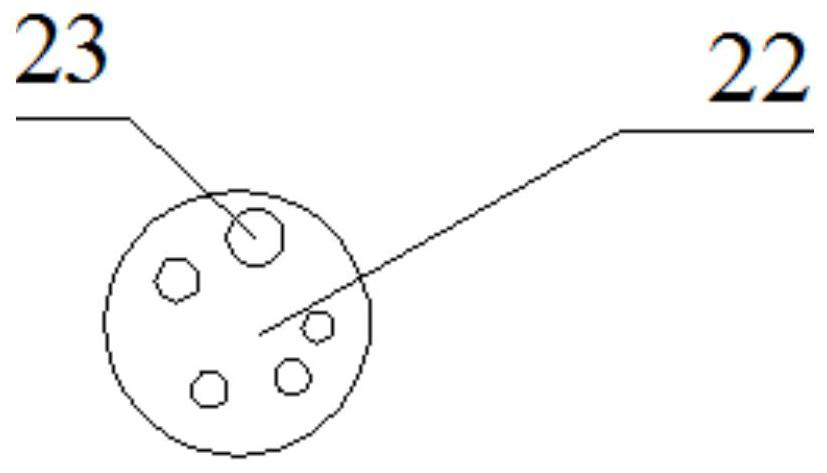

[0105] This embodiment provides a sewage treatment system, the schematic diagram of which is as follows: figure 2 shown, from figure 2 It can be seen that the sewage treatment system includes a sewage treatment tank 3, a set of dynamic membrane bioreactors 5 provided in Example 1, a motor 4, an aeration pump 7 and a finished water tank 11. The sewage treatment tank 3 Activated sludge is contained in the middle, the movable membrane bioreactor 5 is arranged below the sewage level of the sewage treatment tank 3, and the upper end cover 17 of the movable membrane bioreactor 5 is electrically connected with the rotating shaft of the motor 4 , the surrounding, the bottom and the idle shaft 13 of the movable membrane bioreactor 5 are provided with aeration pipes 12;

[0106] The dynamic membrane bioreactor 5 and the aeration pipe 12 are arranged in the plastic mesh 21, and the aeration pipes 12 arranged around and at the bottom of the dynamic membrane bioreactor 5 and the dynamic...

Embodiment 3

[0117] This embodiment provides a sewage treatment method, wherein the sewage treatment method is realized by using the sewage treatment system provided in Embodiment 2, and the method includes the following specific steps:

[0118] (1) Sewage (COD is 300-500mg / L) enters the sewage treatment tank through the first flow meter through the water pump, and the activated sludge in the sewage treatment tank adsorbs and degrades the organic matter in the sewage;

[0119] (2) After the sewage treated by the activated sludge in step (1) enters the hollow fiber membranes of the moving membrane bioreactor, the moving membrane bioreactor is rotated, and the hollow fiber membranes are placed in the hollow fiber membranes. The water is subjected to solid-liquid separation, and product water is obtained after separation. The product water finally flows into the second water collecting pipe in the lower end cover, collects the product water through a suction pump, and sends it to the finished ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com