Petroleum coke desulfurization method

A petroleum coke, high sulfur technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of poor desulfurization effect, high energy consumption, large investment, etc., to promote removal, reduce mass transfer resistance, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

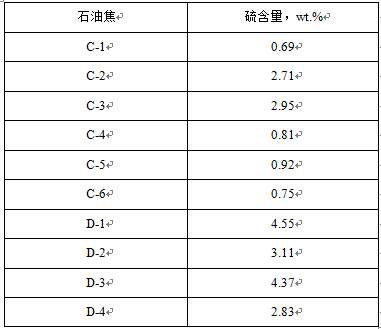

Embodiment 1

[0030] Take 100g of petroleum coke and mix it with 50g of sodium hydroxide evenly, place it in a tube furnace, heat it up to a temperature of 700°C under a nitrogen atmosphere, and heat treatment for 20min. The activated sample was washed with deionized water until the pH value of the filtrate was neutral. 50 g of material A and 150 g of DMF were treated at 80°C for 12 hours, washed to neutrality, and dried at 120°C for 6 hours to obtain material B. use N 2 O 4 Gas, at an airspeed of 500h -1 , 40°C and 1 atm, the material B was processed for 10 h, and the material C was obtained. Material C was further heated to 700°C in a power microwave field with a frequency of 2450 MHz and a power of 4 kW, and the temperature was kept constant for 1 h. Then take 150g of deionized water to wash 50g of material C, and the washing time is 4h. Desulfurized petroleum coke is obtained, which is denoted as C-1.

Embodiment 2

[0032] Take 100g of petroleum coke and mix with 5g of potassium hydroxide evenly, place it in a tube furnace, heat it up to a temperature of 500°C under a nitrogen atmosphere, and heat treatment for 20min. The activated sample was washed with deionized water until the pH value of the filtrate was neutral. 50 g of material A and 250 g of DMF were treated at 60°C for 12 hours, washed to neutrality, and dried at 120°C for 6 hours to obtain material B. Use high-purity NO2 Gas, at an airspeed of 1000h -1 , 50°C and 1 atm, the time for processing material B is 10h, and material C is obtained. Material C was further heated to 700°C in a power microwave field with a frequency of 2450 MHz and a power of 4 kW, and the temperature was kept constant for 1 h. Then take 150g of deionized water to wash 50g of material C, and the washing time is 4h. Desulfurized petroleum coke is obtained, which is denoted as C-2.

Embodiment 3

[0034] Take 100g of petroleum coke and mix it with 50g of sodium hydroxide evenly, place it in a tube furnace, heat it up to a temperature of 700°C under a nitrogen atmosphere, and heat treatment for 20min. The activated sample was washed with deionized water until the pH value of the filtrate was neutral. 50 g of material A and 150 g of DMF were treated at 80°C for 12 hours, washed to neutrality, and dried at 120°C for 6 hours to obtain material B. The concentration used is 50%N 2 O 4 gas (nitrogen as carrier gas) at a space velocity of 500 h -1 , 60°C and 2 atm, the time for processing material B is 10h, and material C is obtained. Material C was further heated to 700°C in a power microwave field with a frequency of 2450 MHz and a power of 1 kW, and the temperature was kept constant for 0.5 h. Then take 150g of deionized water to wash 50g of material C, and the washing time is 4h. Desulfurized petroleum coke is obtained, which is denoted as C-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com