Sieving equipment for high-purity rounded quartz powder and sieving control method of high-purity rounded quartz powder

A technology of quartz powder and rounded corners, which is applied to chemical instruments and methods, filters, instruments, etc., can solve the problems of increasing workflow and reducing screening efficiency, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

[0038] Application overview

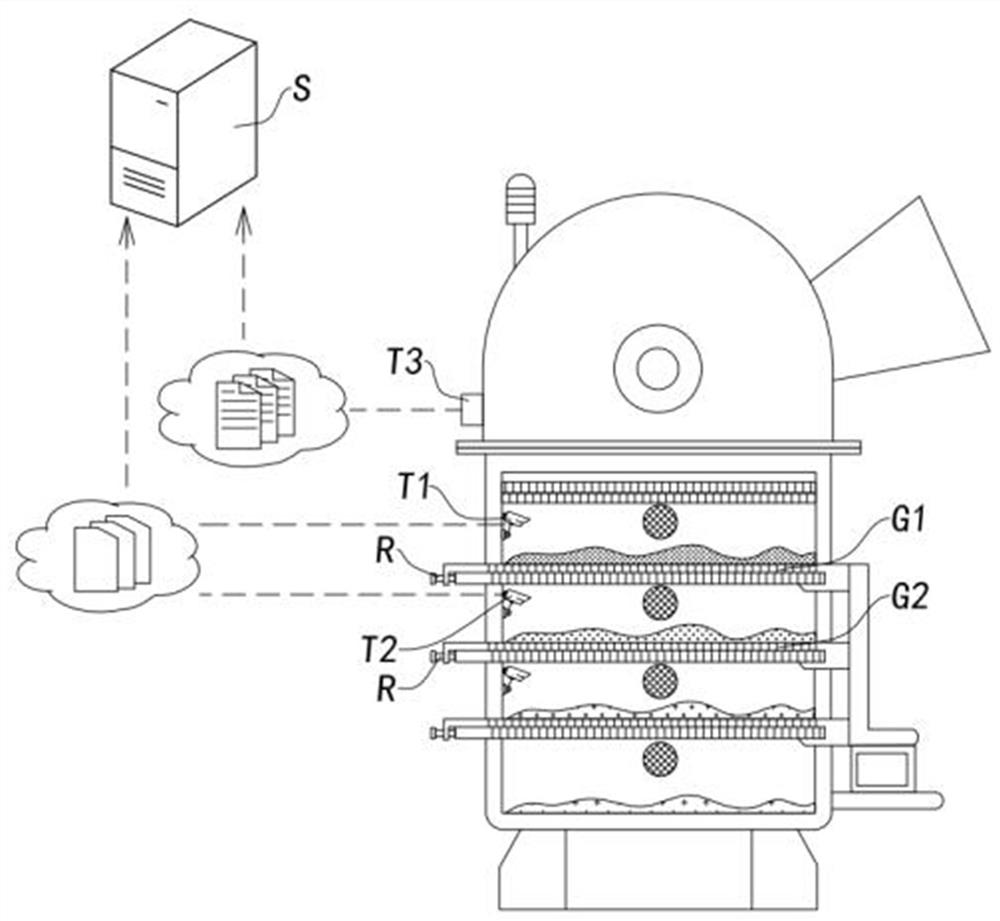

[0039] Compared with the traditional screening equipment, the technical idea of the present application is to construct a screening equipment with multi-stage screening and crushing mechanisms, that is, as Figure 1A As shown, the screening device includes at least two screening layers and at least one crushing mechanism M at the structural end. For example, when the screening device includes two screening layers, the screening device includes an upper screening layer. The layer G1, the lower sieving layer G2, and the crushing mechanism M provided on the upper sieving layer G1.

[0040] Considering that the quartz raw material of the upper sieving layer G1 has different particle sizes after being crushed by the crushing mechanism M, therefore, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com