System and method for monitoring whole process of sealant preparation

A monitoring system and sealant technology, which is applied in logistics, data processing applications, instruments, etc., can solve the problems of theoretical deployment ratio filling errors, low efficiency, and inconvenient use of sealants, so as to reduce the difficulty of calculation, reduce economic losses, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

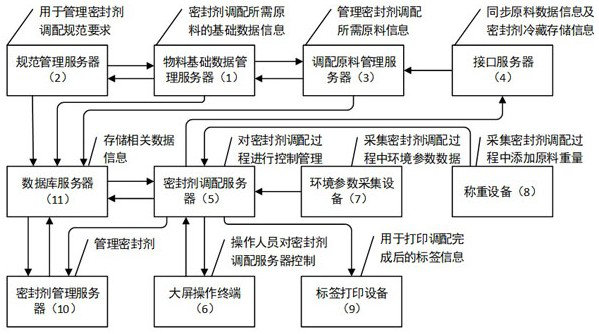

[0030] This embodiment is a monitoring system for the whole process of sealant configuration, such as figure 1 As shown, the system includes a material basic data management server 1, a specification management server 2, a preparation material management server 3, an interface server 4, a sealant preparation server 5, a large-screen operation terminal 6, an environmental parameter collection device 7, and a weighing device 8 , label printing equipment 9, sealant management server 10 and database server 11; these servers and equipment are connected through the Internet of Things, and corresponding application software and special software are deployed on each server.

[0031] In this embodiment, the material basic data management server 1 is used to define basic information such as the code, name, and grade of the material, and can define unit conversion. Since most of the purchased raw materials are counted by sticks, barrels, etc., the unit conversion described is to convert ...

Embodiment 2

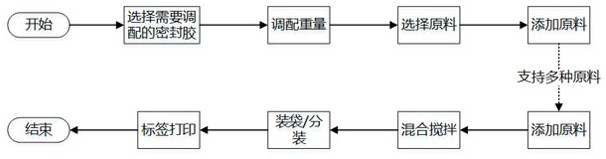

[0039] In this embodiment, the system described in Embodiment 1 is used to monitor the whole process of sealant configuration, such as figure 2 shown.

[0040] First, the sealant configuration personnel use the large-screen operation terminal 6 to select the sealant to be prepared this time. After the selection is completed, enter the configuration weight filling in this time. After the weight filling is completed, enter the raw material selection page.

[0041] The raw material selection page is screened based on the raw material types required for the sealant configuration defined in the specification management server 2, and only the information of the raw material types that meet the requirements is displayed. After selecting the corresponding raw materials, go to the next step.

[0042] The large-screen operation terminal 1 panel of the system automatically prompts the relevant specifications of the current sealant configuration, and automatically calculates the required...

Embodiment 3

[0047] In this embodiment, the system described in Embodiment 1 is used to realize the management and tracking of the sealant after configuration.

[0048]Four states of the sealant are defined in the sealant management server 10 , which are refrigerated storage, thawing, scrapped, and normal use. After the preparation of the sealant is completed, it is in normal use. The normally used sealant shall manage and remind the construction period of the sealant. For sealants that are configured too much at one time or do not need to be used temporarily, refrigerated storage can be performed. The sealant configuration staff selects the corresponding sealant after configuration. After clicking on refrigerated storage, the sealant status changes to refrigerated storage and the label print The equipment reprints the refrigerated label, and the system manages and reminds the expiration date of the sealant in the refrigerated storage. When the sealant in the refrigerator needs to be tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com