Switchable comprehensive mechanical load test equipment

A technology for testing equipment and mechanical loads, which is applied in the testing of machines/structural components, the use of stable tension/pressure to test the strength of materials, and the testing of optical instruments. It can solve complex equipment manipulation, high cost, and heavy weight of metal sheets problems, to achieve the effect of high safety performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

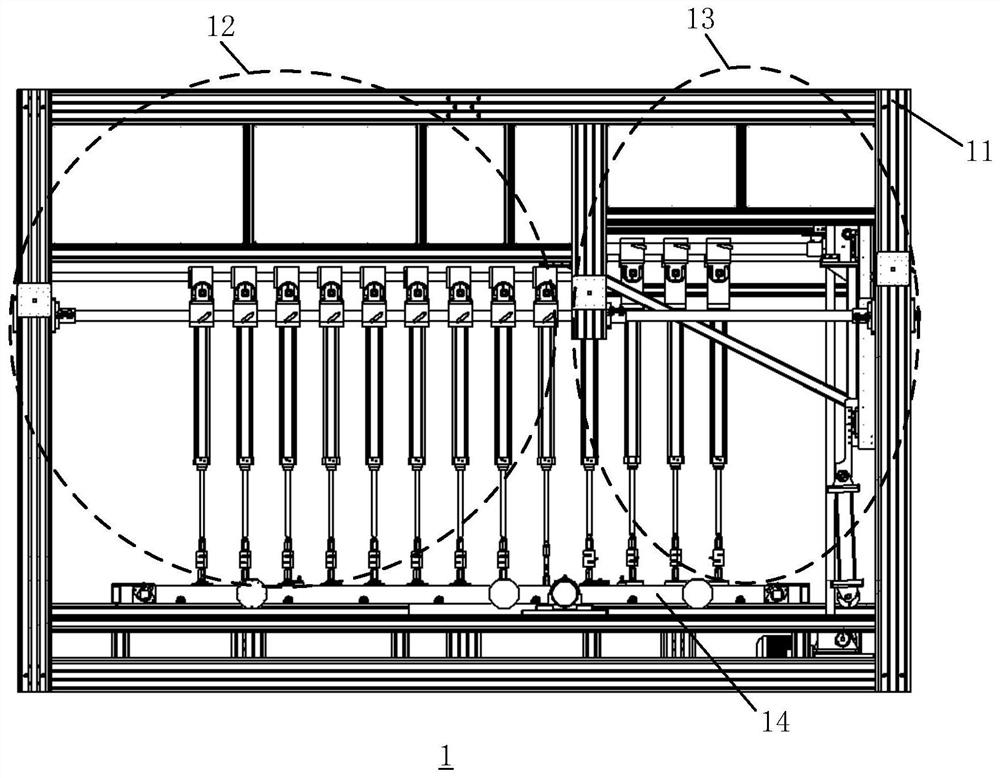

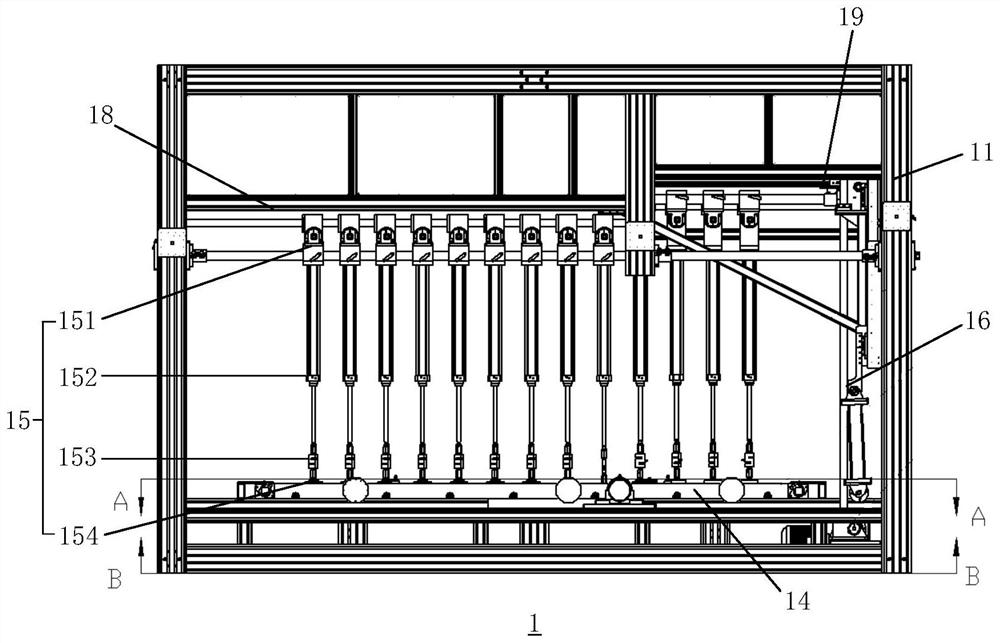

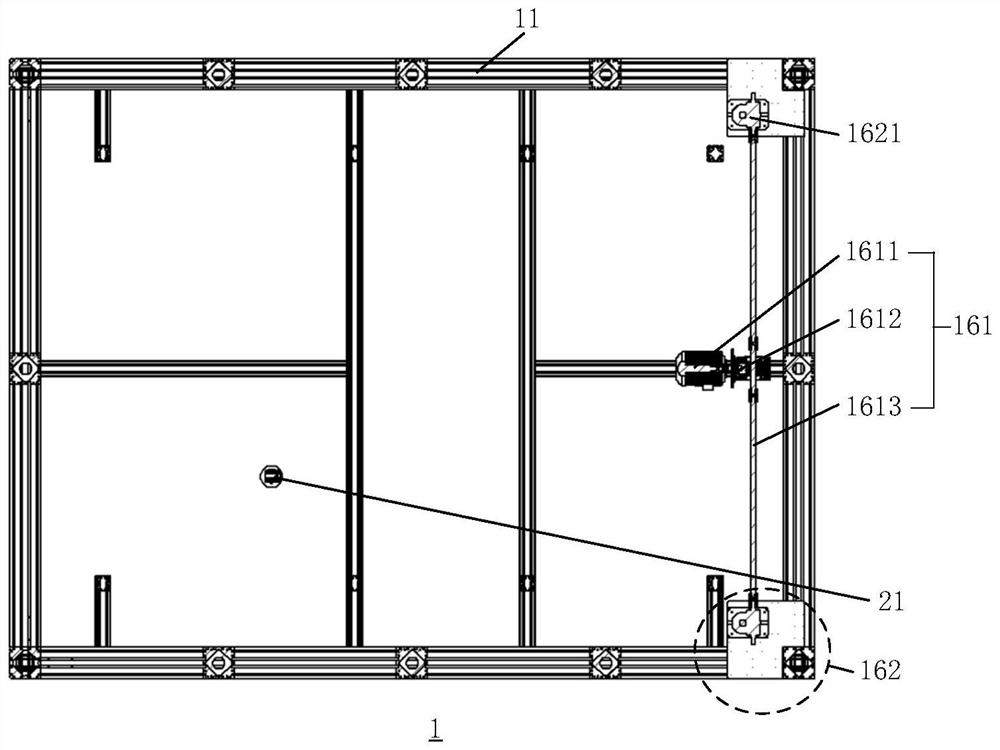

[0057] The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the drawings in the embodiments of the present application. Obviously, the described embodiments are only a part of the embodiments of the present application, but not all of the embodiments. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present application.

[0058] The present application will be further described below with reference to the accompanying drawings and embodiments.

[0059] First, briefly introduce the terms involved in the embodiments of this application:

[0060] Turbine and worm components are used to transmit motion and power between two staggered shafts. The worm wheel and worm are equivalent to gears and racks in their midplane, and the worm is similar in shape to the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com