Drilling equipment for processing plastic cover plate of washing machine and operation method of drilling equipment

A technology of drilling equipment and operation methods, which is applied in metal processing and other directions, and can solve problems such as uneven positions, inability to align plastic cover plates, and prone to defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

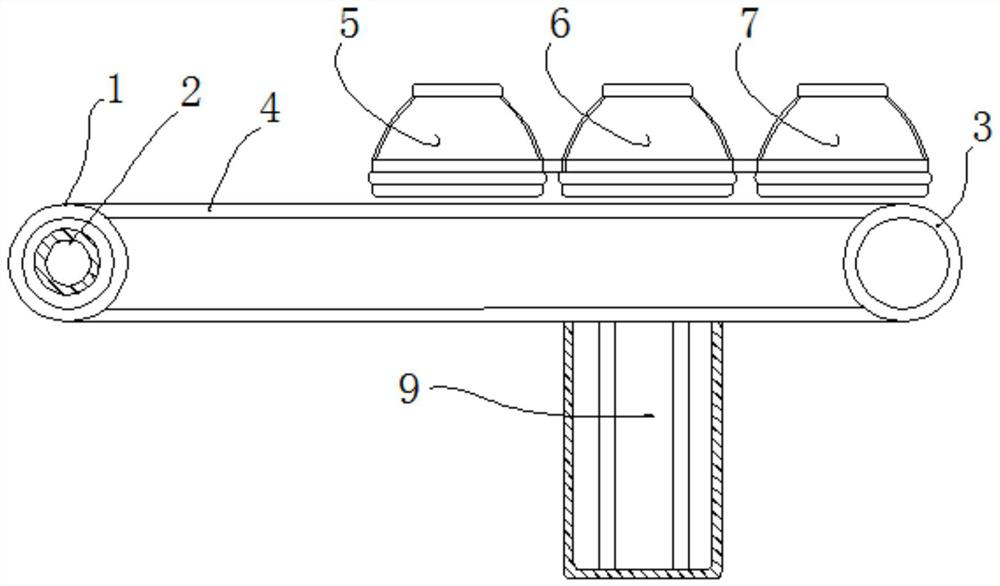

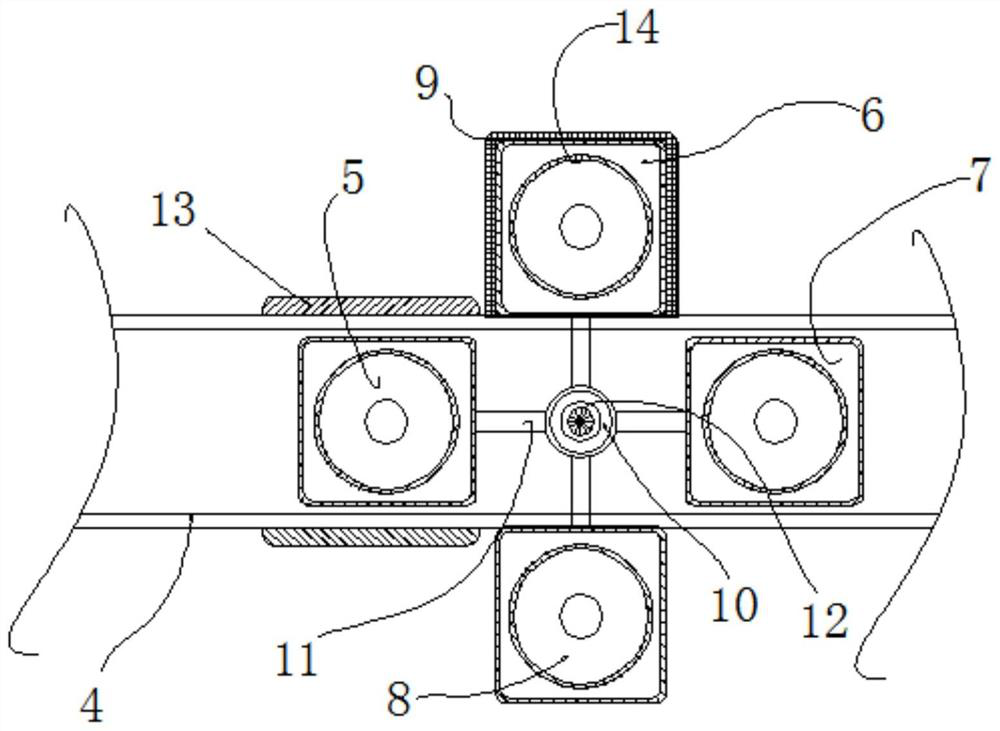

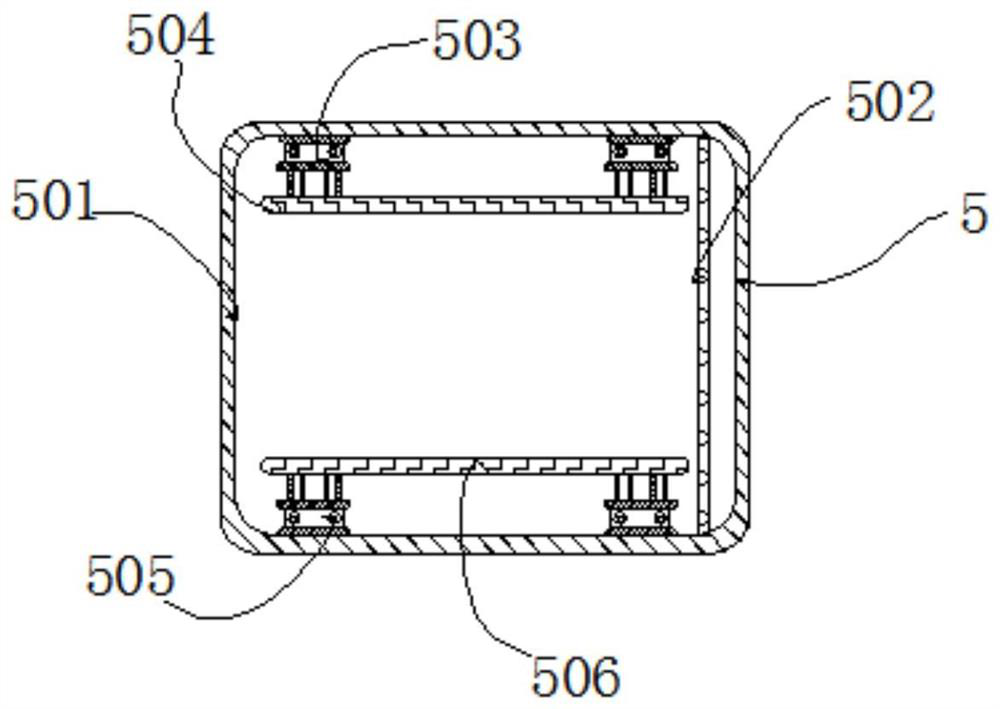

[0034] see Figure 1-7 , the present invention provides a technical solution: a drilling device for processing a plastic cover of a washing machine and an operation method thereof, comprising a left wheel 1, a first motor 2 is installed inside the left wheel 1, and a right side of the left wheel 1 is installed. A right revolving wheel 3 is installed, a conveyor belt 4 is installed between the left revolving wheel 1 and the right revolving wheel 3, and a first clamping mechanism 5, a second clamping mechanism 6, and a third clamping mechanism are installed above the conveyor belt 4 respectively. 7 and the fourth clamping mechanism 8, the first motor 2 drives the left wheel 1 to rotate, so that the left wheel 1 drives the right wheel 3 and the conveyor belt 4 to rotate, and the plastic cover of the washing machine rotates from the left wheel 1 to the right wheel. The direction of 3 is conveyed on the top of the conveyor belt 4. A punching mechanism 9 is installed below the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com