Device for automatically cutting wind power flange sample by numerical control lathe and cutting method

A wind power flange and CNC lathe technology, applied in the direction of sampling device, feeding device, positioning device, etc., can solve the problems of insufficient cutting accuracy, difficulty in moving, high failure rate, etc., to ensure safe and stable operation, improve cutting accuracy, and reduce failures rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

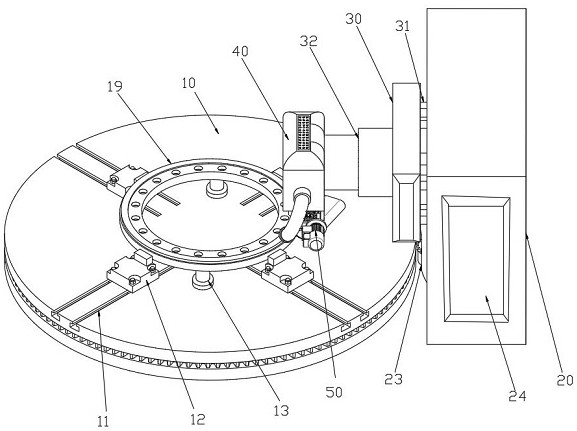

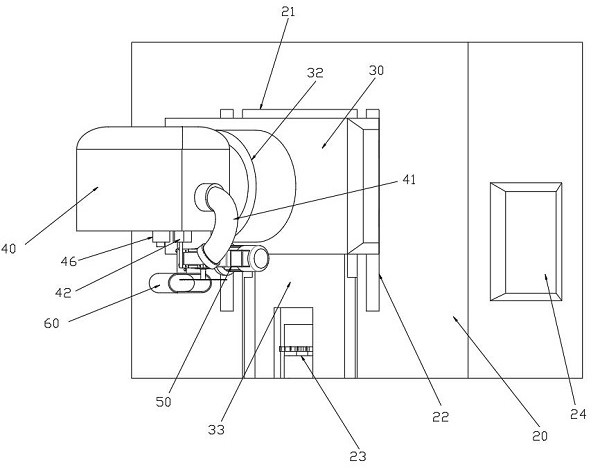

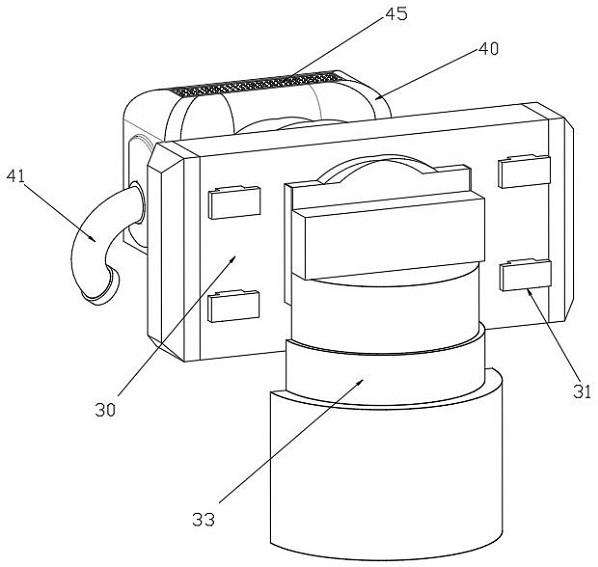

[0035] refer to Figure 1-4 , a device for automatically cutting wind power flange samples by a numerical control lathe, including a bearing turntable 10 and a lathe frame 20, the bearing turntable 10 is a rotatable mechanism, the upper end of the bearing turntable 10 carries a wind power flange 19, A lathe frame 20 is arranged on the side; a vertical hydraulic lift 33 is embedded at one end of the lathe frame 20, and a turntable motor 23 is arranged at the lower part of the lathe frame 20; The lower end of the vertical hydraulic lifter 33 is provided with a turntable gear 15, which meshes with the turntable motor 23; the output end of the vertical hydraulic lift 33 is provided with a bearing bracket 30, and one side of the bearing bracket 30 is connected to the lathe frame 20. In sliding connection, a horizontal hydraulic lift 32 is fixedly arranged on the other side of the support bracket 30 ; an equipment box 40 is fixedly arranged at the output end of the horizontal hydrau...

Embodiment 2

[0043] This embodiment is a cutting method of a device for automatically cutting a wind power flange sample using a numerically controlled lathe involved in the first embodiment, and the method for cutting a wind power flange sample includes the following steps:

[0044] Step S1: First, according to the diameter of the wind power flange 19, preset the position where the wind power flange 19 is placed on the bearing turntable 10, and according to the position, place the support column 13 evenly along the circumference at the lower part where the wind power flange 19 is to be placed , the wind power flange 19 is hoisted to a preset position by a crane, so that the support column 13 is carried in the middle of the circumference of the wind power flange 19;

[0045] Step S2: After the wind power flange 19 is stably placed in the preset position, the fixing bolts 18 are inserted into the turntable chute 11, the mounting holes of the limit assembly 12 are sleeved on the fixing bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com