Gas particulate matter removal method

A particle removal technology, applied in separation methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of wasteful removal of particles, easy re-contamination of particles, secondary pollution, etc., to avoid tilting or Dumping, reducing energy consumption, slowing down the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

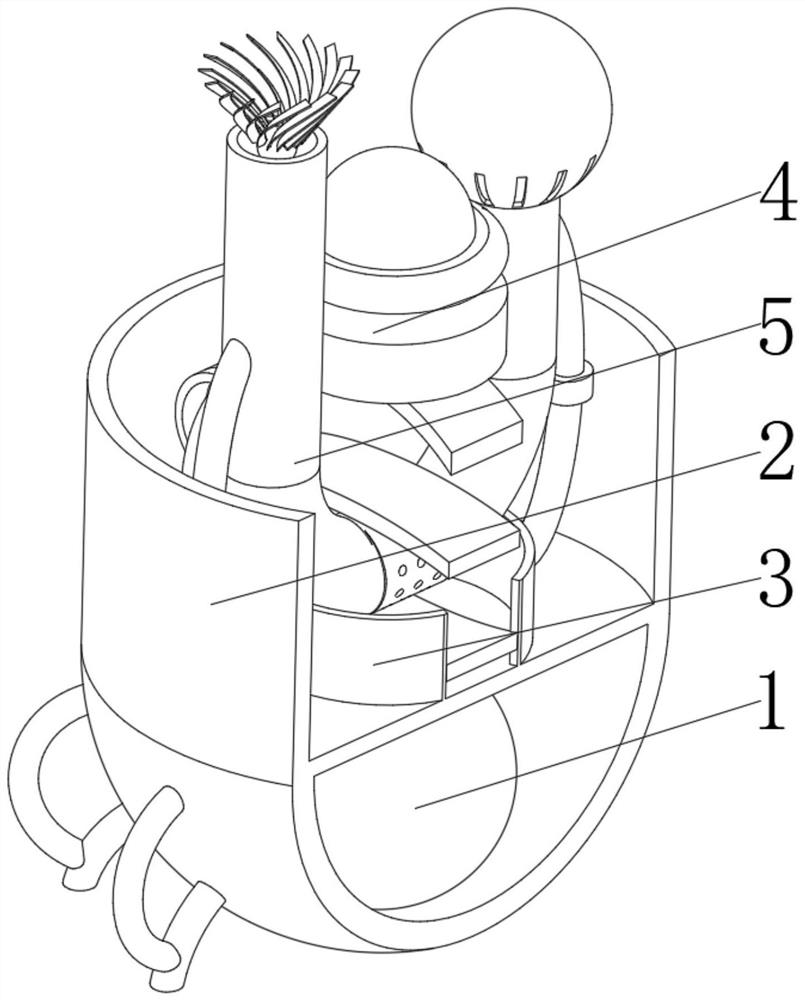

[0040] see Figure 1-6 , the present invention provides a technical solution: a gas particulate removal device, which specifically includes:

[0041] Base 1, the base 1 has a hemispherical body, a water-soluble tank 2 installed on the top of the hemispherical body, a protective device 3 installed at the bottom of the inner cavity of the water-soluble tank 2, and an adjustment device 4 installed on the top of the protective device 3. The separation device 5 on the inner surface of the protective device 3, the separation device 5 includes:

[0042] The removal pipe 51 has a U-shaped pipe body, a precipitation hole 52 opened in the middle of the bottom of the U-shaped pipe body, and an arc-shaped guide pipe 53 installed on both sides of the outer surface of the U-shaped pipe body, and A small water pump 54 installed in the middle of the arc-shaped diversion pipe 53, a spherical aspirator 55 installed at the low end of the U-shaped pipe body, and an air seal device 56 installed a...

Embodiment 2

[0052] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for removing gas particulate matter, comprising the following steps:

[0053] Step 1: inject clean water into the inner cavity of the water soluble tank 2 until the protective device 3 is submerged, and store the initial electric energy inside the center of gravity energy storage ball 12 in the base 1;

[0054] Step 2: Start the spherical aspirator 55 through the electric energy inside the center of gravity energy storage ball 12 to absorb the outside air, and start the small water pump 54 at the same time, so that the clean water in the water-soluble tank 2 is injected into the inside of the removal pipe 51;

[0055] Step 3: Start the rotating motor 43 to make the friction hemisphere 44 rotate, drive the spherical aspirator 55 to rotate through friction, carry out full-scale air suction, and inject the air into the water flow and countercurrent flushing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com