Flexible wall surface resistance reduction and pulsating pressure reduction effect testing device and use method

A pulsating pressure and effect testing technology, applied in measuring devices, fluid dynamics testing, testing of machine/structural components, etc., can solve the problems of low reliability of numerical simulation, and achieve compact structure, convenient operation and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

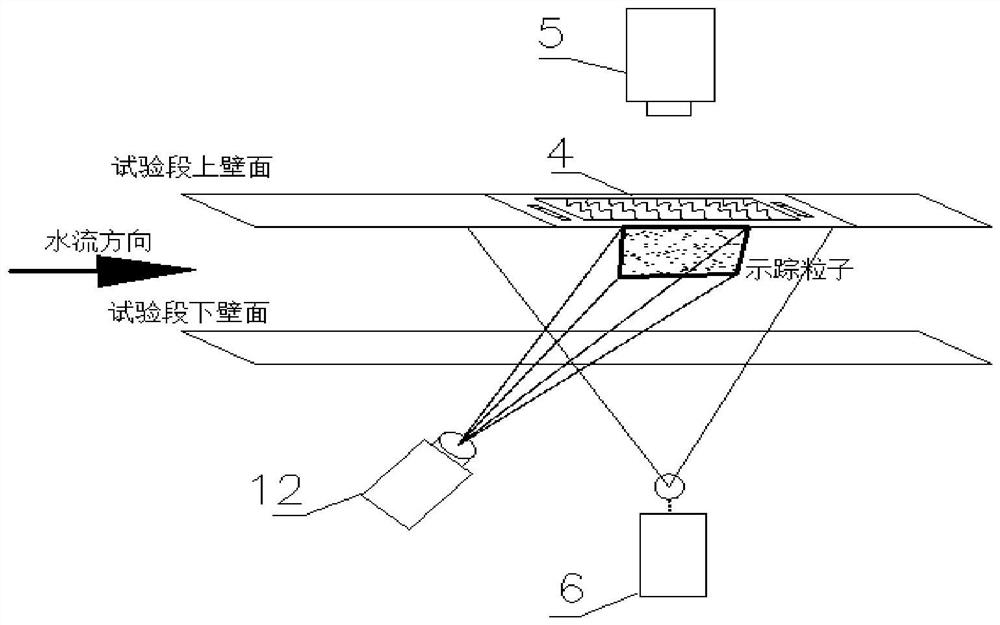

[0039] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

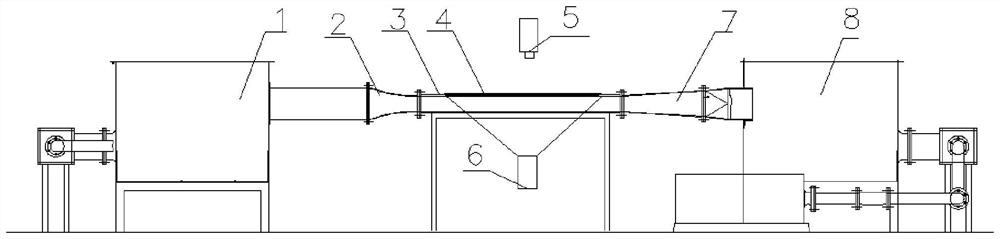

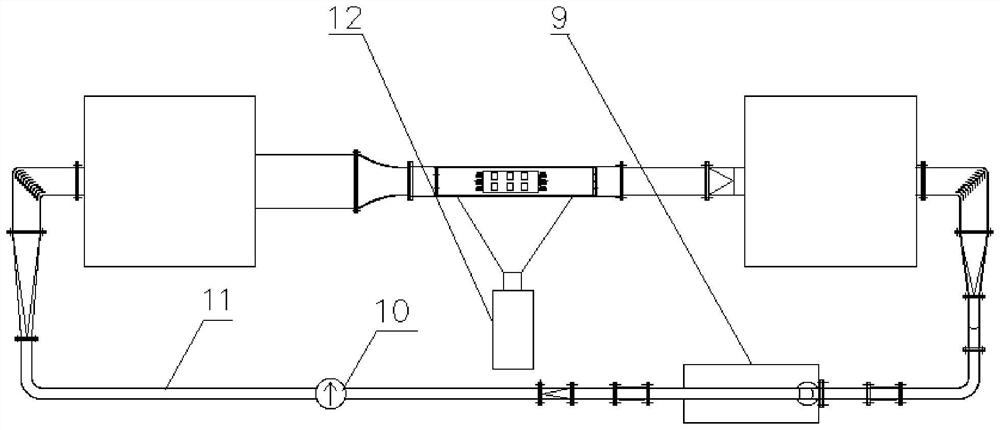

[0040] like Figure 1-Figure 6 As shown, the device for testing the effect of drag reduction and pulsation pressure reduction on the flexible moving wall surface in this embodiment includes a water channel module, a flexible moving wall surface sensing actuation unit 4 and a measurement module,

[0041] The water circuit module includes a test section 3, an inflow channel, an outflow channel, and a return channel that are connected to each other;

[0042] The flexible motion wall sensing actuating unit 4 includes a substrate 404 and a skin 405 disposed on the base 404, and a plurality of single dielectric elastomer actuators are provided on the side of the substrate 404 away from the skin 405; the flexible motion wall sensing actuating unit 4 Set at test section 3,

[0043] The measuring device includes several sensors, the sensors are arranged upst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com