Mining tunneling multimode combined positioning method and system

A combined positioning and multi-mode technology, applied in directions such as navigation through speed/acceleration measurement, can solve problems such as difficult application, difficult autonomous and accurate measurement of the position and posture of the cantilever type roadheader, and inability to obtain the position and posture information of the roadheader, etc., to achieve Accurate positioning and solving the effect of irrelevant data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

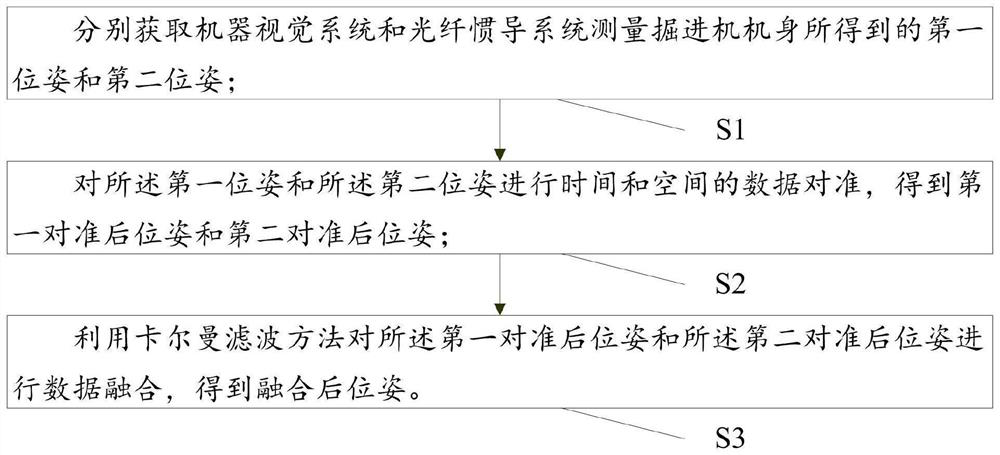

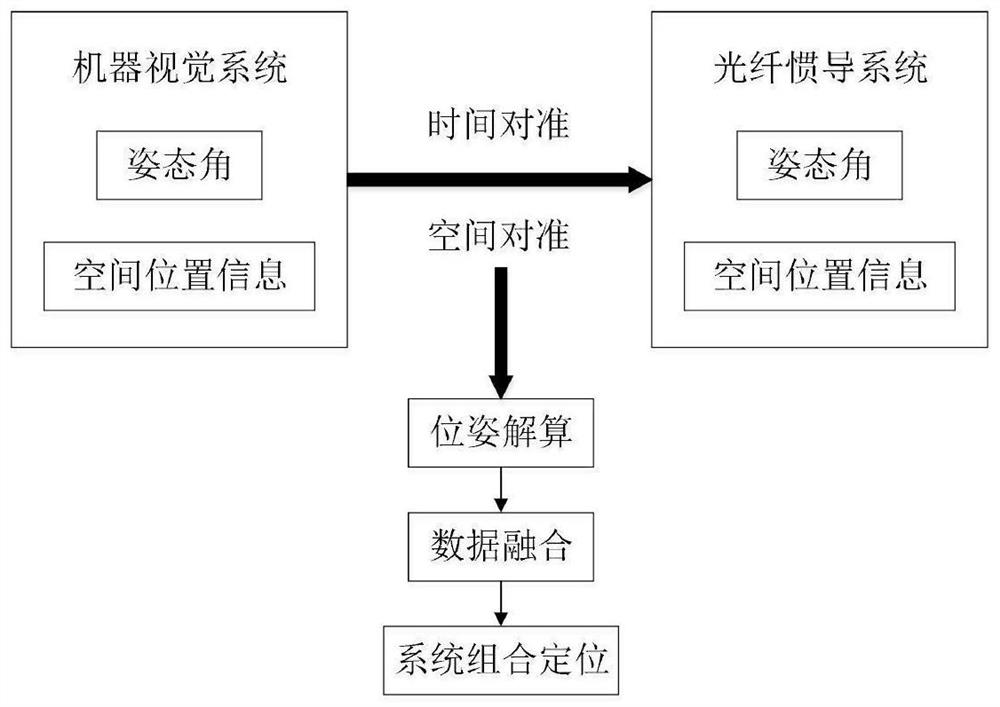

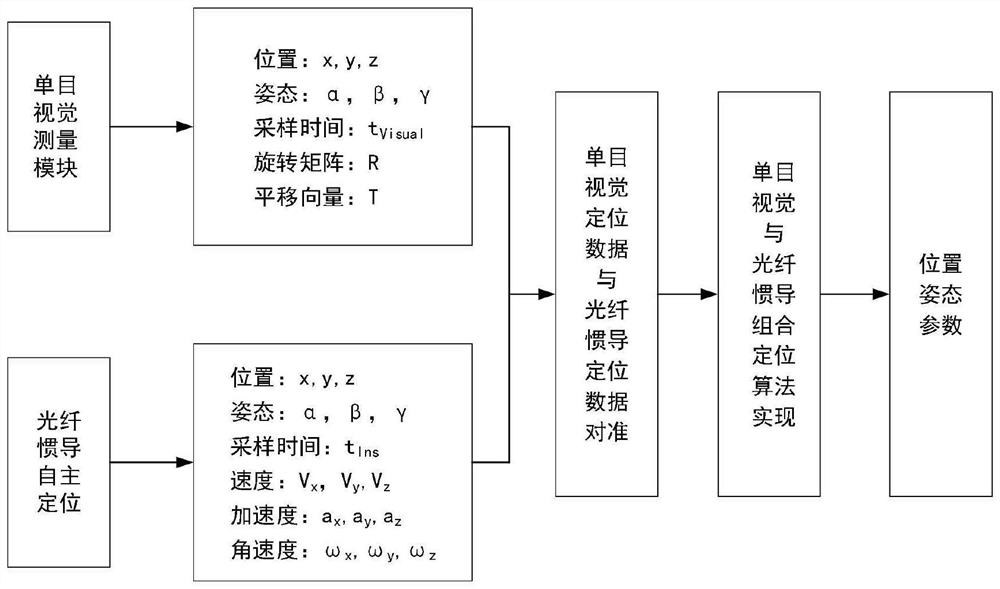

[0029] This embodiment is used to provide a multi-mode combined positioning method for mining tunneling, which is suitable for real-time monitoring of the running state of the tunneling machine in a coal mine, and can obtain the precise running position of the body of the tunneling machine. like figure 1 , figure 2 and image 3 As shown, the combined positioning method includes:

[0030] S1: Obtain the first pose and the second pose obtained by the machine vision system and the fiber optic inertial navigation system to measure the body of the roadheader respectively;

[0031] The machine vision system may be a machine monocular vision measurement system. The first posture includes the body posture information of the roadheader, and the second posture includes the attitude angle and spatial position information of the body posture of the roadheader.

[0032] Specifically, in S1, acquiring the first attitude obtained by the machine vision system measuring the body of the ro...

Embodiment 2

[0152] This embodiment is used to provide a multi-mode combined positioning system for mining excavation, such as Figure 9 As shown, the combined positioning system includes:

[0153] The pose measurement module M1 is used to obtain the first pose and the second pose obtained by the machine vision system and the fiber optic inertial navigation system respectively by measuring the body of the roadheader;

[0154] The data alignment module M2 is used for performing time and space data alignment on the first pose and the second pose to obtain the first aligned pose and the second aligned pose;

[0155] The data fusion module M3 is configured to perform data fusion on the first aligned pose and the second aligned pose by using the Kalman filtering method to obtain the fused pose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com