Oil-gas long-distance pipeline device with plugging function

A long-distance pipeline, oil and gas technology, applied in the direction of pipe components, pipes/pipe joints/fittings, flange connections, etc., can solve the problems of inconvenient maintenance, easy water corrosion of pipelines, and pipelines that cannot be sealed in time, so as to facilitate maintenance , prevent corrosion damage, and prevent continuous leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

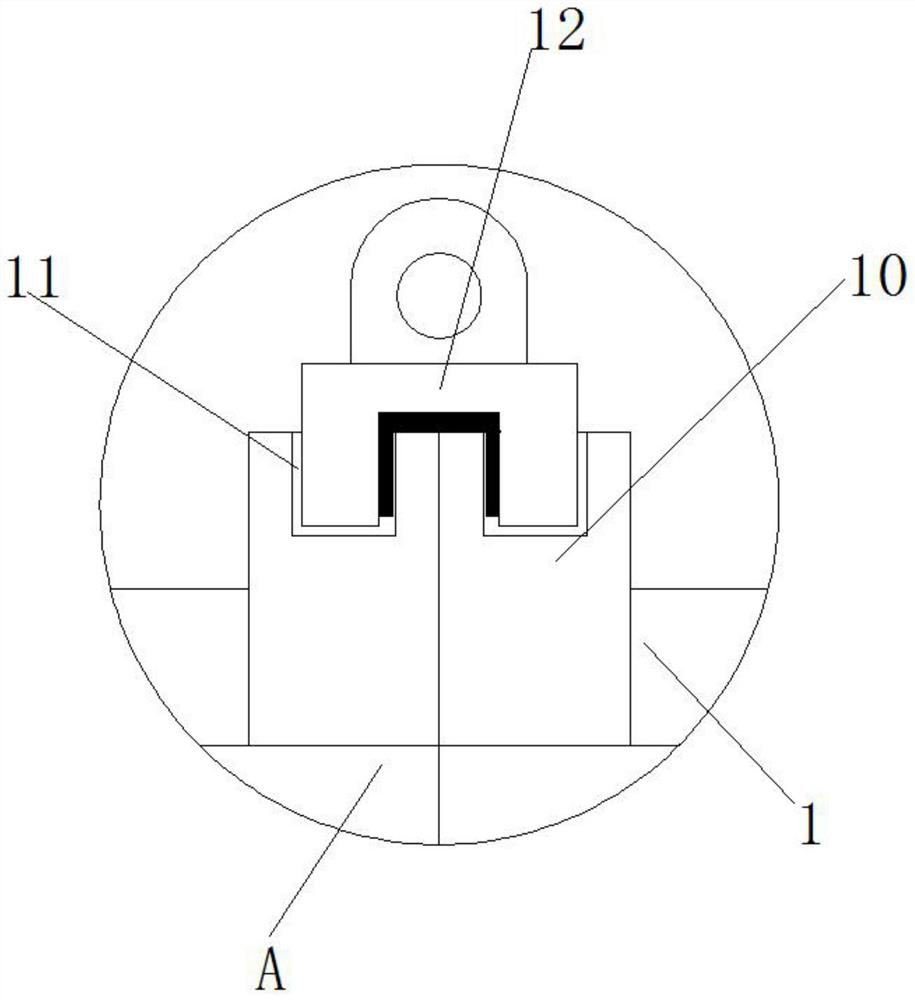

[0042] Example 1, as Figure 7-8 As shown in the figure, there is a leak somewhere in the pipeline. At this time, slide the nearest sliding ring 309 to the leaking place, and rotate the sliding ring 309 to rotate the mounting frame 301 to the top of the leaking place. At this time, pull the handle 308 to drive the telescopic The rod 304 moves upward, the handle 308 drives the first thorn rack 306 to move upward, the teeth on the first thorn rack 306 and the second thorn rack 1303 slide with each other, and the upwardly moving telescopic rod 304 is driven by the first rack 302 The two sets of gears 305 rotate, and the two sets of gears 305 push the second rack 307 toward the leak. At this time, the sealing block 303 is close to the leak and blocks it, which can be temporarily blocked and prevented from leaking. At the same time, the two sets of springs 1302 The second thorn rack 1303 is engaged with the first thorn rack 306 to prevent the handle 308 from moving in the opposite ...

Embodiment 2

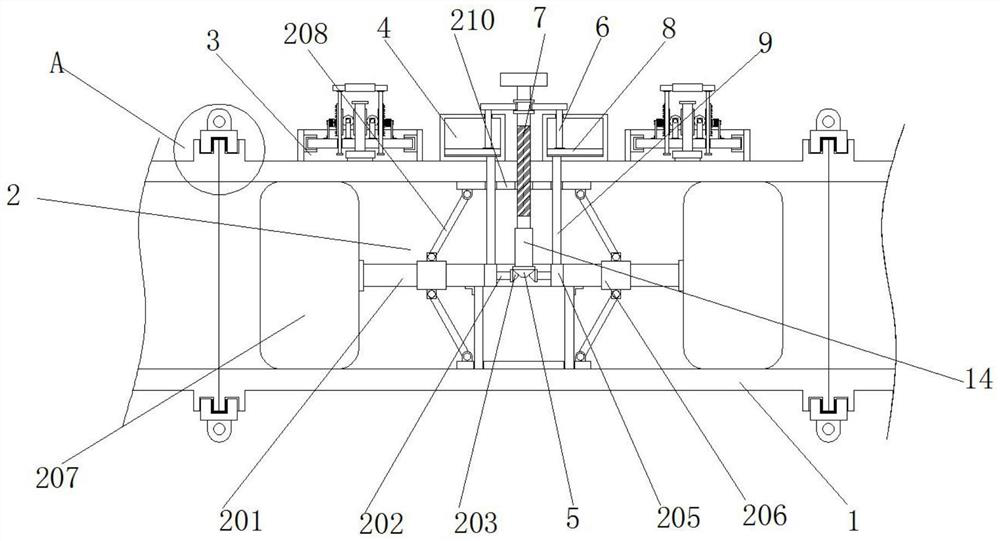

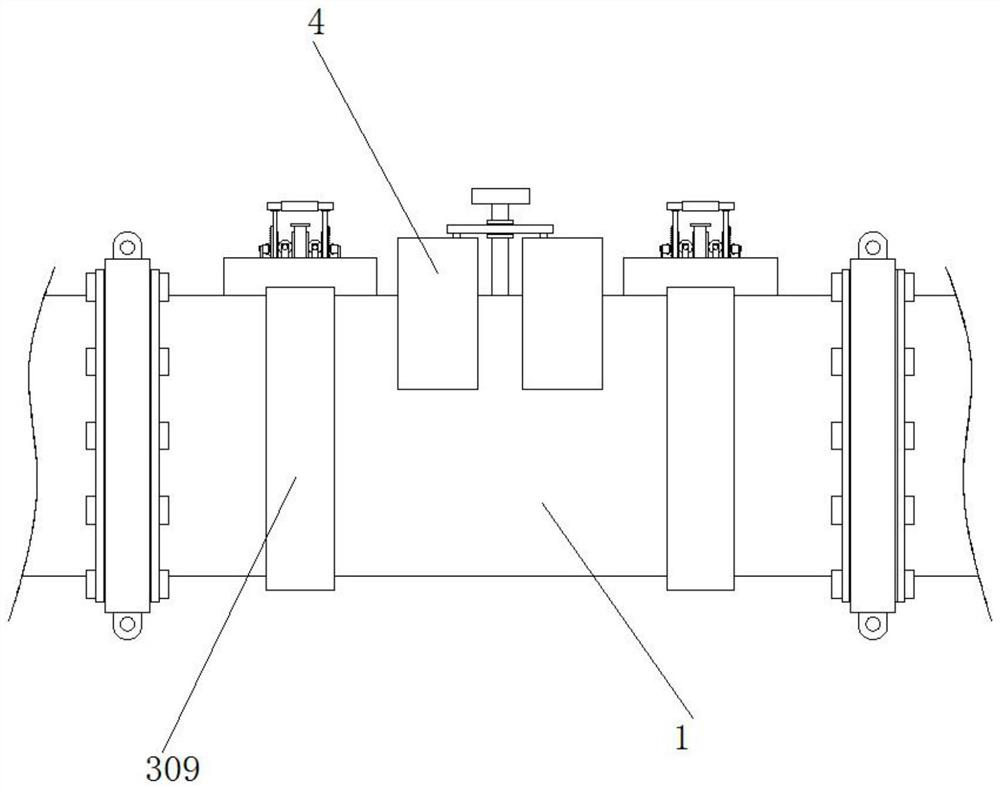

[0043] Example 2, as Figure 1-6 As shown, when a certain section of pipeline needs to be repaired, disassembled and replaced, the second threaded rod 7 is rotated at this time, so that the second threaded rod 7 moves to the inside of the pipeline 1, and the second threaded rod 7 drives the pressing rod 6 and the arc The shaped plate 8 moves downward, so that the arc-shaped plate 8 transports the air inside the air storage chamber 4 through the conduit 9, the connecting chamber 205 and the air intake pipe 204 to the interior of the air bag 207, so that the air bag 207 is expanded, and the pipeline is blocked and blocked. At the same time, the second threaded rod 7 drives the sleeve 14 and the first bevel gear 5 to rotate, and the first bevel gear 5 drives the first threaded rod 202 to rotate through the two sets of second bevel gears 203 , so that the sliding sleeve 206 slides on the outside of the connecting rod 201 , the top plate 210 is pushed to the outside of the pipe 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com