Jet fuel cabin high-speed ventilation valve and ventilation system for ship

A technology of jet fuel and breathable valve, which is applied to some cabins, hulls, ships and other directions in the hull, can solve the problems of inability to use directly for reference, and achieve the effect of compact structure, small overall space occupation, and improved operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For a better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

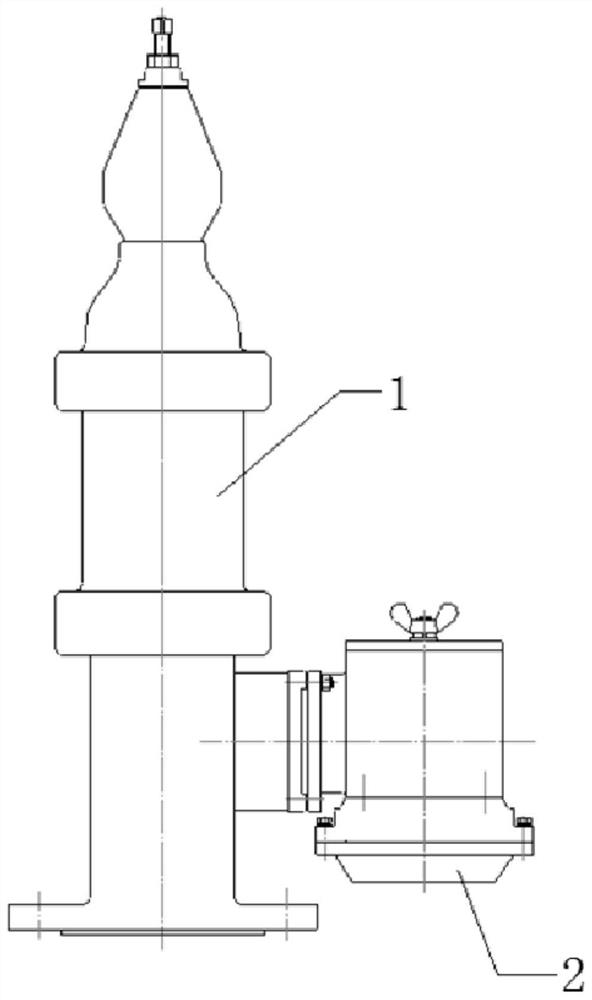

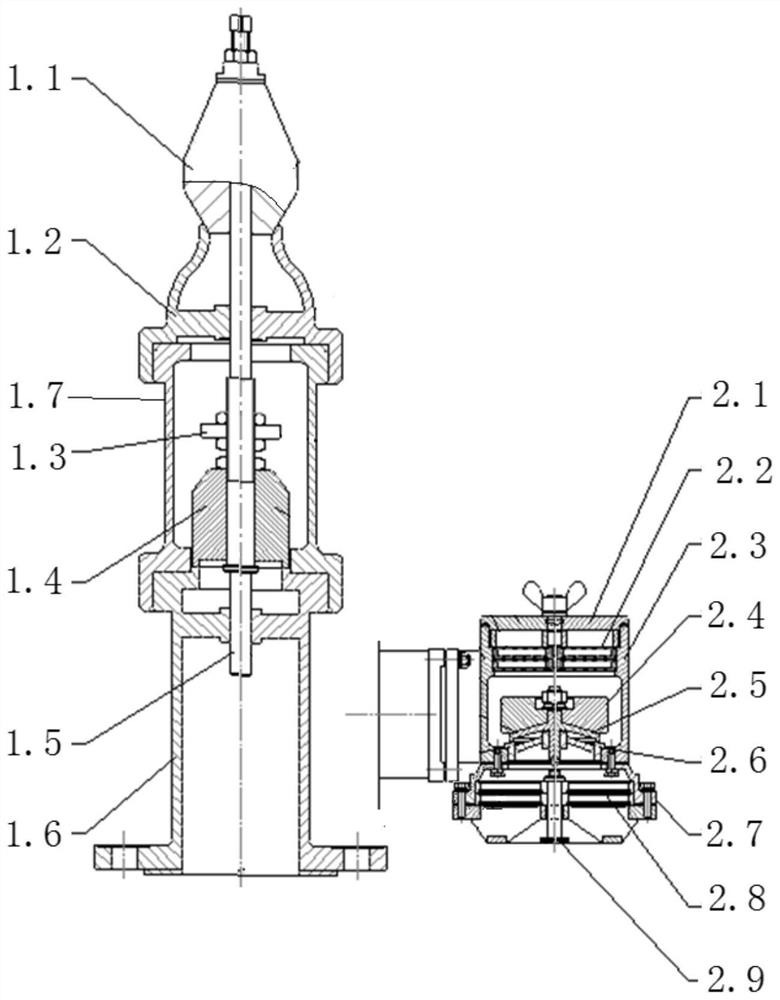

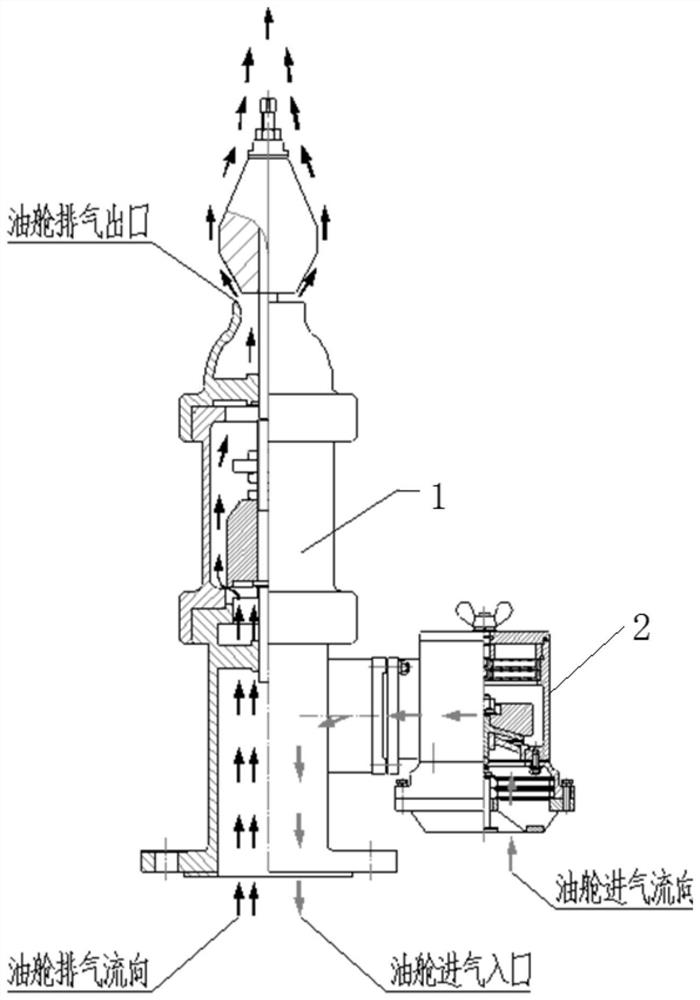

[0026] like figure 1 and figure 2 The shown high-speed venting valve for a jet fuel tank for a surface ship specifically includes a pressure valve assembly 1 and a vacuum valve assembly 2. The pressure valve assembly 1 includes a pressure valve body, a pressure valve stem 1.5, a valve disc 1.4 and a flush valve. Disc 1.3, the pressure valve body includes an upper pressure valve body 1.2, a pressure valve middle valve body 1.7 and a pressure valve lower valve body 1.6 that are vertically arranged and communicated from top to bottom in sequence; the pressure valve upper valve body 1.2 The top is communicated with the outside world, and the bottom of the lower valve body 1.6 of the pressure valve is installed on the vertical ventilation pipeline 3 and communicated with the ventilation pipeline 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com