Underground box body structure correction method based on BIM

A box structure and box technology, applied in basic structure engineering, architecture, geometric CAD, etc., can solve problems such as difficulty, high cost, and delay in construction period, and achieve the effects of reducing construction waste, simple correction operation, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

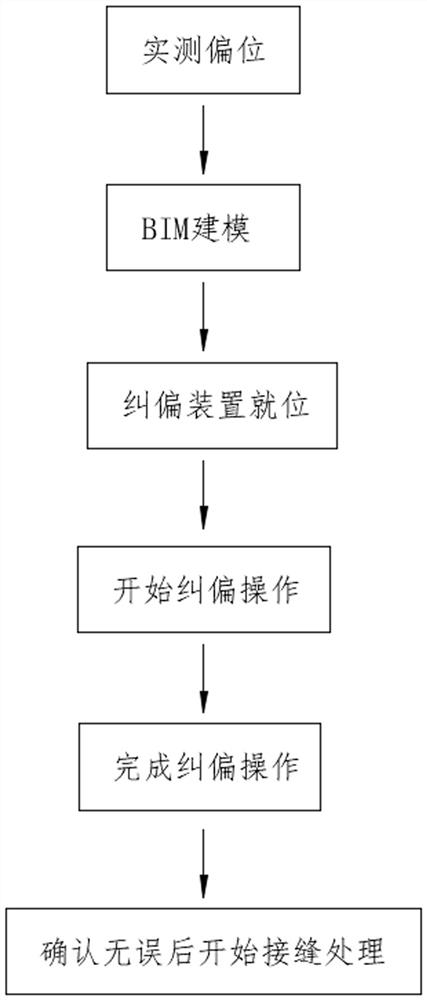

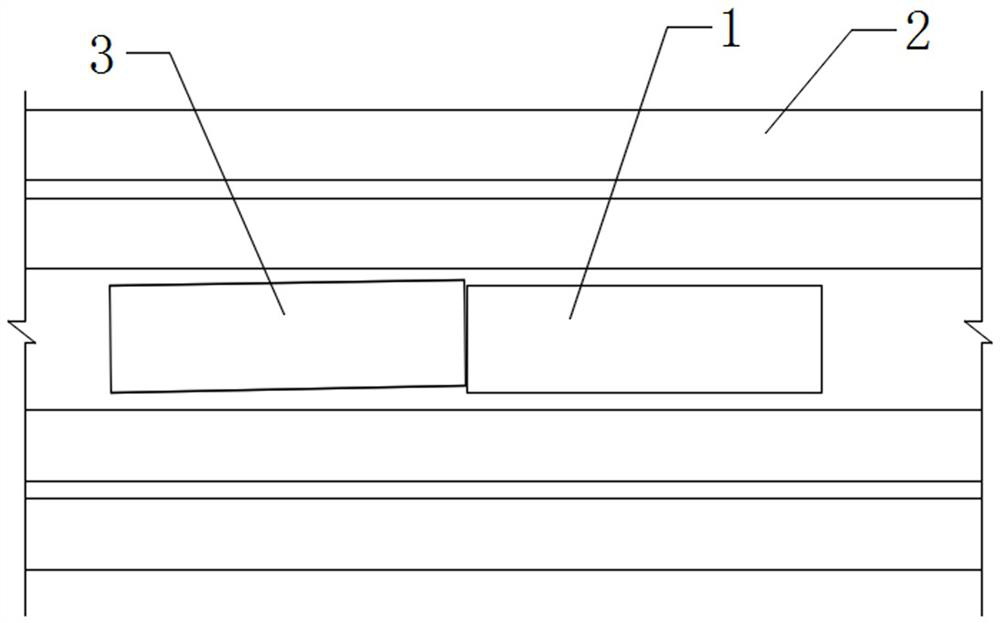

[0038] like Figure 1-6 As shown, the BIM-based underground box structure correction method of the present invention includes the following steps:

[0039] S1. Measured deviation. After the deviation of the box 1 in the foundation pit, the corresponding coordinate points of the deviation are measured on site.

[0040] S2, BIM modeling, build a BIM model according to the offset coordinate points, and judge the deviation from the design position line 4.

[0041] S3. The deviation correction device is in place, and vertical support is adopted, and several jack cylinders 7 are installed between the box body 1 and the support assembly.

[0042] S4. Start the deviation correction operation. Combined with the BIM model, repeatedly adjust several jack cylinders 7 on both sides until the deviation is within the allowable range.

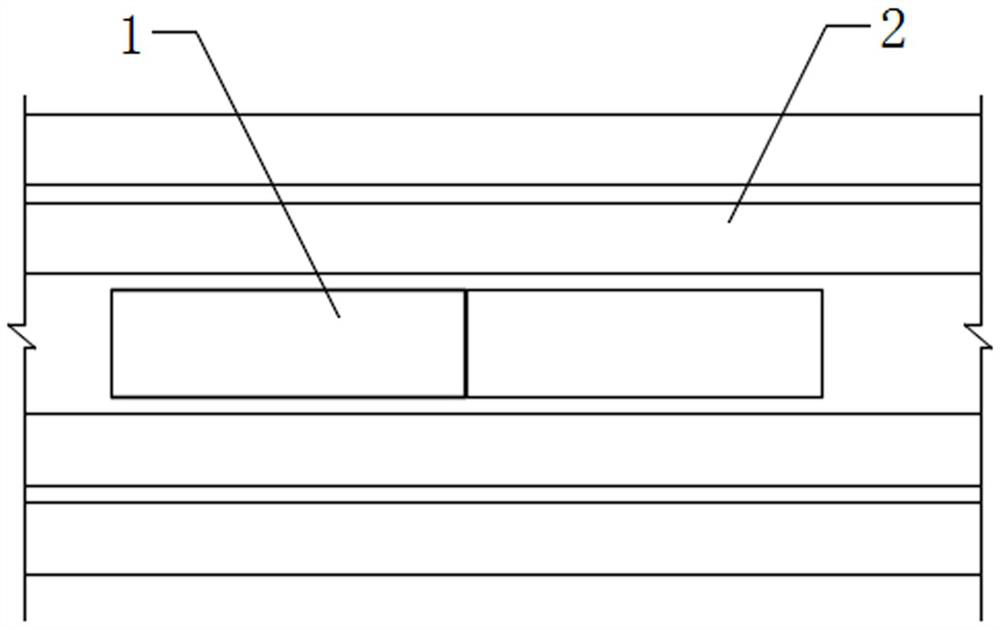

[0043] S5, complete the deviation correction operation.

[0044] S6. Start seam processing after confirming that it is correct.

[0045] In this embodimen...

Embodiment 2

[0055] like Figure 1-6 As shown, the present invention provides a BIM-based method for correcting the structure of an underground box body, and the method for correcting the structure of an underground box body includes the following steps:

[0056] S1. Measured deviation. After the deviation of the box 1 in the foundation pit, the corresponding coordinate points of the deviation are measured on site.

[0057] S2, BIM modeling, build a BIM model according to the offset coordinate points, and judge the deviation from the design position line 4.

[0058] S3. The deviation correction device is in place, and the open I-beam 6 is used for support, and several jack cylinders 7 are installed between the box body 1 and the support assembly.

[0059] S4. Start the deviation correction operation. Combined with the BIM model, repeatedly adjust several jack cylinders 7 on both sides until the deviation is within the allowable range.

[0060] S5, complete the deviation correction operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com