Preparation method of nickel-tungsten composite electrode and application of nickel-tungsten composite electrode in electrocatalytic oxidation

A composite electrode, nickel-tungsten technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., to achieve the effect of high conversion rate of raw materials, wide source of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

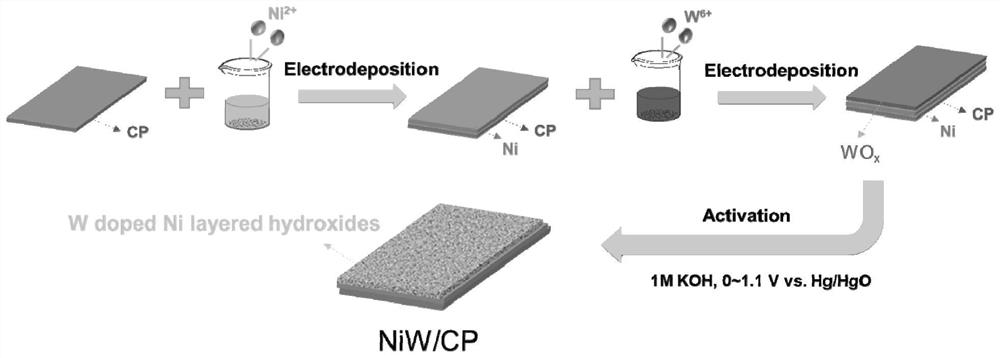

[0037] like figure 1 As shown in the present embodiment, a method for preparing a nickel-tungsten electrode, the specific operations are as follows:

[0038] (1) Pretreatment of carbon paper: the used hydrophilic carbon paper is washed with ethanol and water for many times, and then dried in air;

[0039] (2) Electrodeposition of nickel: Electrodeposition was carried out in a 100ml beaker using a two-electrode system with carbon paper as the cathode and carbon rod as the anode. The nickel deposition electrolyte is: 6 mmol nickel sulfate hexahydrate, 2.40 g boric acid, 8.82 g sodium citrate dihydrate, 1.80 g sodium chloride and 60 mL ultrapure water are dissolved in a beaker, and sulfuric acid is added to adjust the pH of the electrolyte to 6.0. Deposition current is -200mAcm at 25°C -2 , and the deposition time was 30 min. Then rinse several times with water and finally dry;

[0040] (3) Electrodeposition of tungsten: Electrodeposition was carried out in a 100ml beaker, us...

Embodiment 2

[0046] like figure 1 As shown in the present embodiment, a method for preparing a nickel-based electrode material, the specific operations are as follows:

[0047] (1) Pretreatment of carbon paper: the used hydrophilic carbon paper is washed with ethanol and water for many times, and then dried in air;

[0048] (2) Electrodeposition of nickel: Electrodeposition was carried out in a 100ml beaker using a two-electrode system with carbon paper as the cathode and carbon rod as the anode. The nickel deposition electrolyte is: 6 mmol nickel sulfate hexahydrate, 2.40 g boric acid, 8.82 g sodium citrate dihydrate, 1.80 g sodium chloride and 60 mL ultrapure water are dissolved in a beaker, and sulfuric acid is added to adjust the pH of the electrolyte to 6.0. Deposition current is -0.20Acm at 25°C -2 , and the deposition time was 30 min. Then rinse several times with water and finally dry;

[0049] (3) Activation of the electrode material: using the admiral electrochemical workstat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com