Process for recovering and reusing tribromophenol in bromotriazine production wastewater

A technology of tribromophenol and bromotriazine, which is applied in the field of recovery and reuse of tribromophenol in bromotriazine production wastewater, can solve problems such as workshop odor, large amount of solid waste, etc. The effect of reducing the treatment cost and solving the large amount of solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

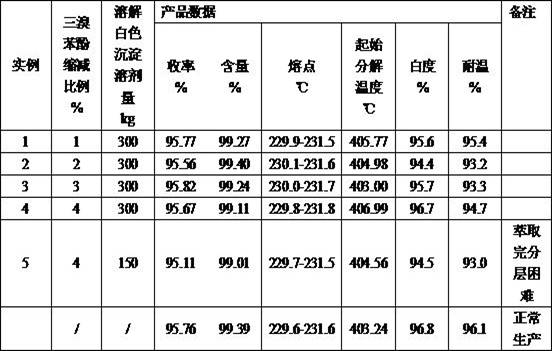

Examples

Embodiment 1

[0023] Get the alkaline waste water 6500kg of tribromophenol, adjust pH to 1~2 with hydrochloric acid, separate out white precipitate tribromophenol;

[0024] Take 60kg of white precipitate, add 300kg of dichloromethane for extraction, let stand for 20min, filter, the organic phase is filtered for later use, and the acidic waste water is discharged into a waste water collection tank;

[0025] The above-mentioned organic phase was transferred into the reactor, 150 kg of sodium sulfite solution was added, the temperature was raised to 37° C., and stirred for 30 min to obtain the recovered tribromophenol, which was used for the preparation of bromotriazine.

[0026] The recovered tribromophenol organic phase and the newly prepared tribromophenol organic phase (reduction ratio 1%) are transferred into the reactor together, add 1000kg deionized water, then add sodium hydroxide solution (according to sodium hydroxide solution and tribromophenol) The weight ratio of the organic phase...

Embodiment 2

[0028] Get the alkaline waste water 6500kg of tribromophenol, adjust pH to 1~2 with hydrochloric acid, separate out white precipitate tribromophenol;

[0029] Take 60kg of white precipitate, add 240kg of dichloromethane for extraction, let stand for 30min, filter, the organic phase is filtered for later use, and the acidic waste water is discharged into a waste water collection tank;

[0030] The above-mentioned organic phase was transferred into the reactor, 330 kg of sodium sulfite solution was added, the temperature was raised to 38° C., and stirred for 30 min to obtain the recovered tribromophenol, which was used for the preparation of bromotriazine.

[0031] The recovered tribromophenol organic phase and the newly produced tribromophenol organic phase (reduction ratio 2%) are transferred into the reactor together, add 1000kg deionized water, then add sodium hydroxide solution (according to sodium hydroxide solution and tribromophenol) The weight ratio of the organic phase...

Embodiment 3

[0033] Get the alkaline waste water 6500kg of tribromophenol, adjust pH to 1~2 with hydrochloric acid, separate out white precipitate tribromophenol;

[0034] Take 60kg of white precipitate, add 200kg of dichloromethane for extraction, let stand for 40min, filter, the organic phase is filtered for later use, and the acidic waste water is discharged into a waste water collection tank;

[0035] The above-mentioned organic phase was transferred into the reaction kettle, 400 kg of sodium sulfite solution was added, the temperature was raised to 38° C., and stirred for 30 min to obtain the recovered tribromophenol, which was used for the preparation of bromotriazine.

[0036] The recovered tribromophenol organic phase and the newly prepared tribromophenol organic phase (reduction ratio 0.03) are transferred into the reactor together, add 1000kg deionized water, and then add sodium hydroxide solution (according to the sodium hydroxide solution and the tribromophenol organic phase). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com