Pig hair peeling and cleaning integrated equipment

A pig hair and equipment technology, applied in climate change adaptation, ink pen repair, printing and other directions, can solve problems such as low efficiency and labor consumption, and achieve the effects of thorough peeling, easy operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

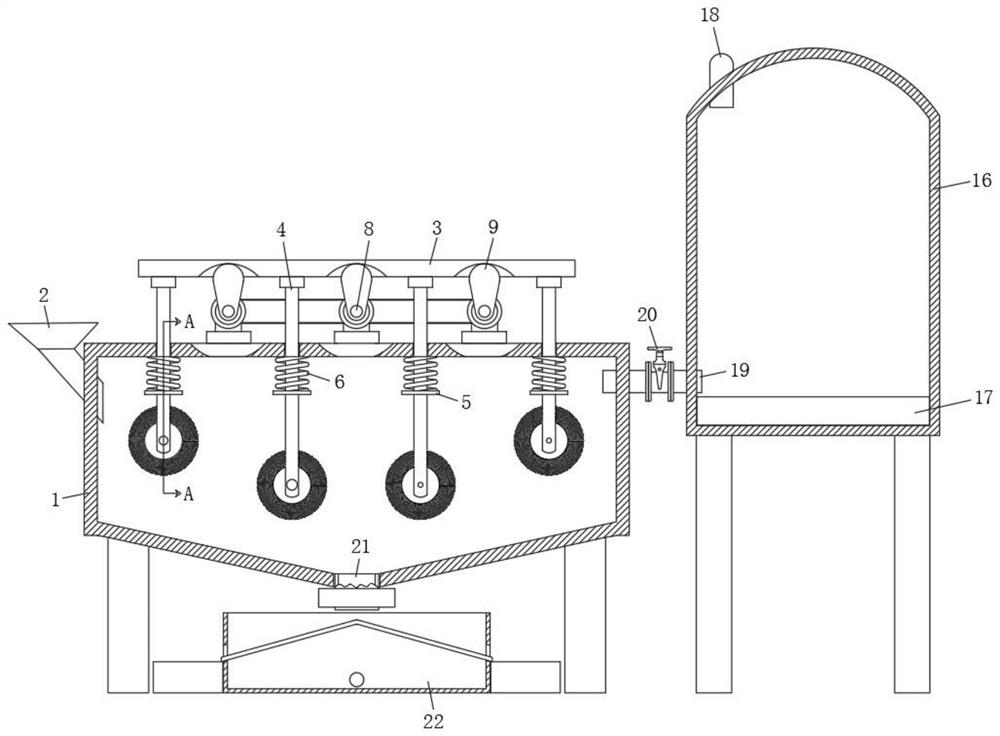

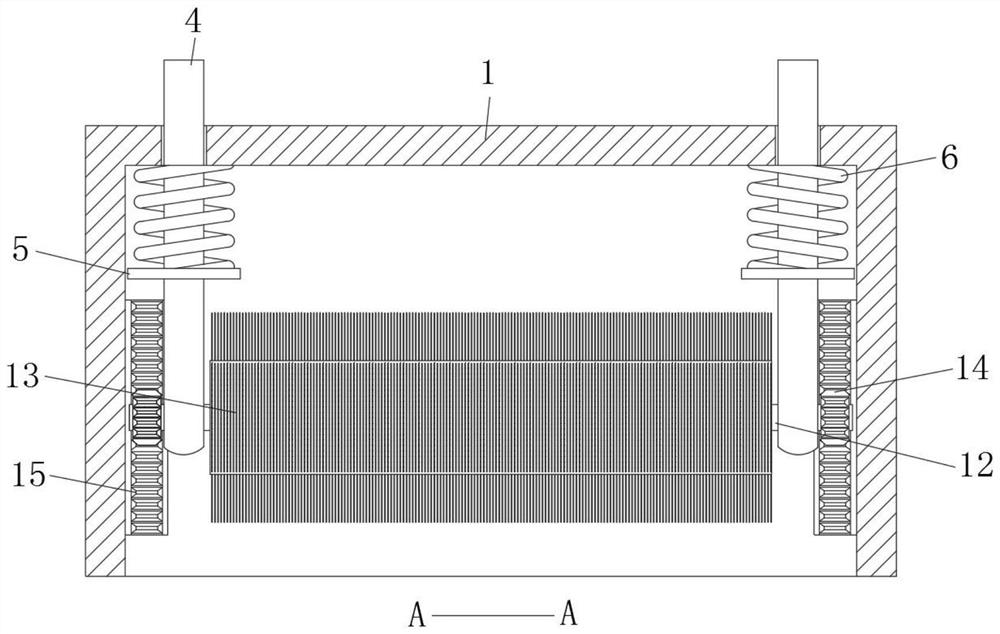

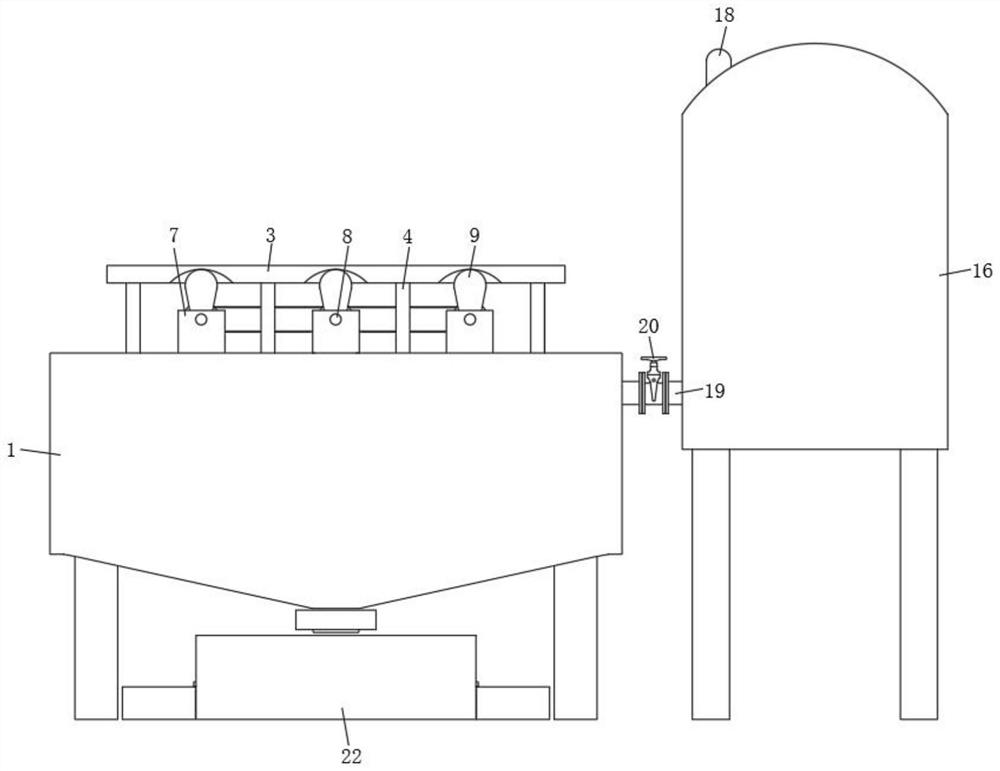

[0027] refer to Figure 1-4 , an integrated equipment for peeling and cleaning pig hair, including a processing box 1, a feeding hopper 2 is throughly connected to one side of the upper end of the processing box 1, and a plurality of pressure rods 4 are slidably connected to the front and rear sides of the top of the processing box 1 to press The rods 4 are evenly distributed on the front and rear sides of the top of the processing box 1, and the two pressure rods 4 on the front and rear sides are located on the same vertical plane. A pull ring 5 is fixed, a return spring 6 is fixed on the top surface of the pull ring 5, the return spring 6 is sleeved on the outside of the pressure rod 4, and the upper and lower ends of the return spring 6 are respectively fixed on the inner top surface of the processing box 1 and the top of the pull ring 5. On the surface, the top surface of the processing box 1 is also installed with a top extension drive assembly for intermittently extendin...

Embodiment 2

[0029] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top extension drive assembly includes a mounting seat 7, and a driving rod 8 is rotatably connected between the two mounting seats 7 in the same group. The rear side extends to the rear side of the mounting seat 7 and is rotatably connected with a synchronous conveyor belt, the front and rear sides of the outer wall of the drive rod 8 are fixed with cams 9, and both sides of the bottom surface of the top plate 3 are provided with arc-shaped grooves that match the cams 9. A horizontal frame 10 is fixed on the rear end side of the box body 1, a driving motor 11 is fixed on the top surface of the horizontal frame 10 by screws, and the output end of the driving motor 11 is fixedly connected with one of the driving rods 8. Each group is provided with two mounting seats 7 and is arranged between two adjacent pressing rods 4, and the initial mounting positions of the cams 9 are th...

Embodiment 3

[0032] like figure 1 and 5As shown, this embodiment is basically the same as Embodiment 1. Preferably, the collecting assembly 22 includes a drain pan 221, the drain net 222 is fixed on the inner walls of the front and rear sides of the drain pan 221, and the two sides of the drain pan 221 are also provided with rectangular grooves 223, and the rectangular The lower side of the outer end of the groove 223 is provided with a hair collecting box 224, a draining pan 221, a draining net 222 is fixed on the inner walls of the front and rear sides of the draining pan 221, and a drain pipe 225 is also connected through the lower side of the front end of the draining pan 221, and the draining net 222 is provided with The two pieces are in close contact with the inner wall of the drain pan 221 , the two drain nets 222 are inclined downward from the middle of the drain pan 221 to both sides, and the lower ends of the drain nets 222 extend to the outside of the rectangular groove 223 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com