Clamping mechanism for wind power flange radial drilling

A technology of clamping mechanism and wind power flange, which is applied in wind power generation, boring/drilling, drilling/drilling equipment, etc. Maintain the stability of the accuracy of the opening of the hole position and other issues, to achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

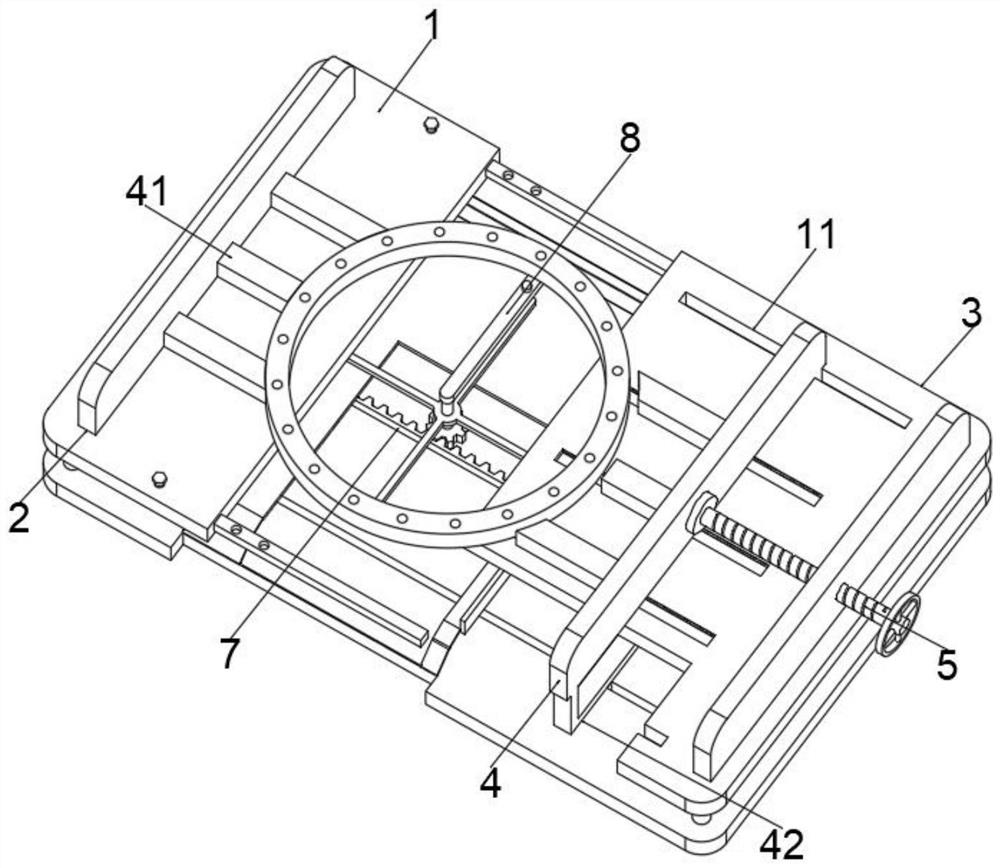

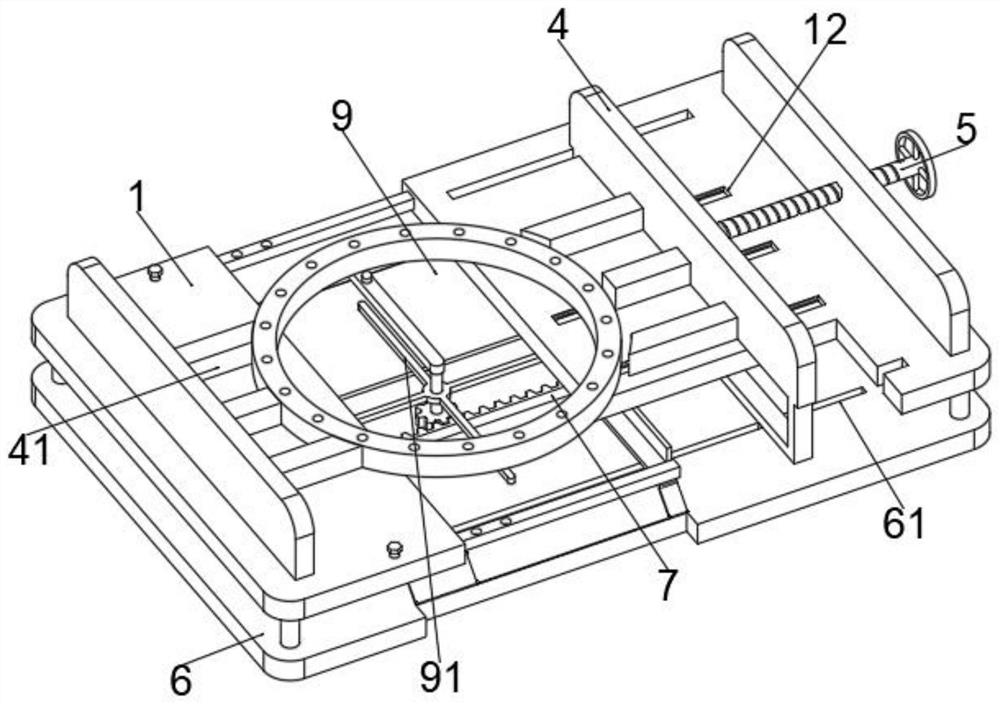

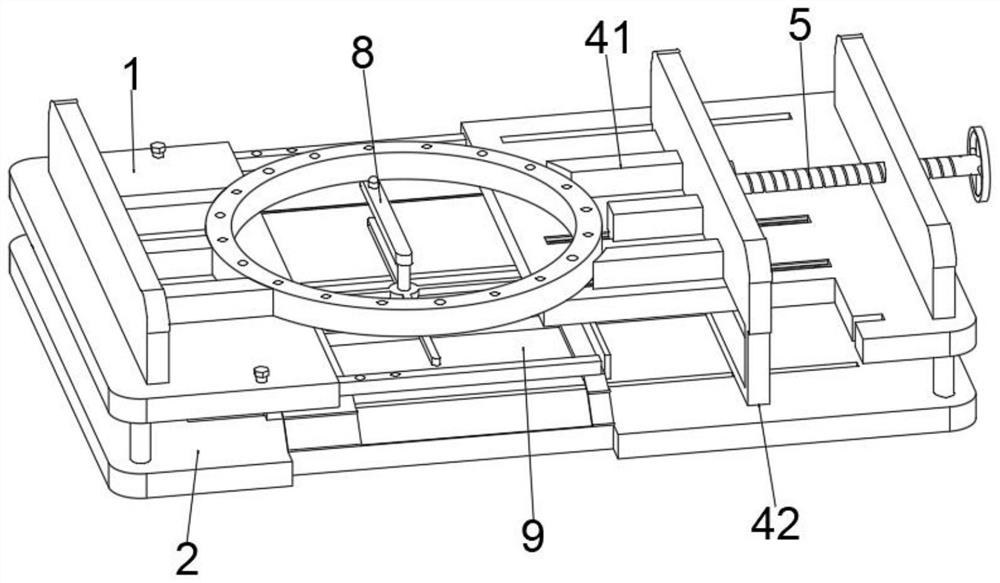

[0037] see Figure 1-Figure 7 As shown, the purpose of this embodiment is to provide a clamping mechanism for radial drilling of wind power flanges, including at least:

[0038] Fixed plate 1, one side of the fixed plate 1 is provided with a positioning plate 3, there is a gap between the fixed plate 1 and the positioning plate 3, and the gap is used to drop the drilling debris of the wind power flange. A mounting plate 2 is installed on the surface, a positioning block 4 is arranged on the surface of the positioning plate 3, and a positioning column 41 is installed on the side of the positioning block 4 and one of the mounting plates 2, and the positioning column 41 is used for clamping the wind power flange. Fixed, a screw 5 is provided between the positioning block 4 and one of the mounting plates 2, the screw 5 is threadedly connected to the mounting plate 2, and the screw 5 is used to push and offset the position of the positioning block 4;

[0039] Support plate 6, the ...

Embodiment 2

[0049] Considering that the positioning column 41 only clamps and fixes the side of the wind power flange, after the wind power flange contacts the drilling equipment, the drilling equipment itself has a large vibration, which will cause the overall wind power flange to shake. This embodiment makes further improvements on the basis of Embodiment 1, such as Figure 8 and Figure 9 shown:

[0050] The surface of the positioning column 41 is provided with a shifting slot 413, the shifting slot 413 extends out of the surface of the positioning column 41, and the inner side of the shifting slot 413 is slidably connected with a pressure block 414, and the pressure block 414 is used for contacting the top side of the wind power flange. After the positioning post 41 is attached to the wind power flange, the pressing block 414 slides along the inner side of the shifting groove 413 to the outside. When the pressure block 414 sticks out to fit the wind power flange, the end position of...

Embodiment 3

[0052] Considering that the gap between the fixed plate 1 and the positioning plate 3 is limited, the rotation of the ring sticking plate 8 will be restricted by the sides of the fixed plate 1 and the positioning plate 3. This embodiment makes further improvements on the basis of the second embodiment, such as Figure 10 shown:

[0053] The surfaces of the fixing plate 1 and the positioning plate 3 are provided with a cavity 13, the cavity 13 is located directly below the wind power flange, and the cavity 13 is used to discharge the debris in the hole of the wind power flange, which is located on the fixed plate through the wind power flange. 1 and the positioning plate 3, and after opening the holes, the partial holes of the wind power flange will be located on the cavity 13, so that the local debris in the holes of the wind power flange will fall down through the cavity 13, When the wind power flange is rotated through the ring plate 8, a small part of the debris in the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com