Chemical reaction temperature control adjusting system and method

A chemical reaction and regulation system technology, applied in control/regulation systems, chemical instruments and methods, temperature control, etc., can solve the problems of waste of water and heat energy, and achieve the effects of automation, labor saving and energy saving media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

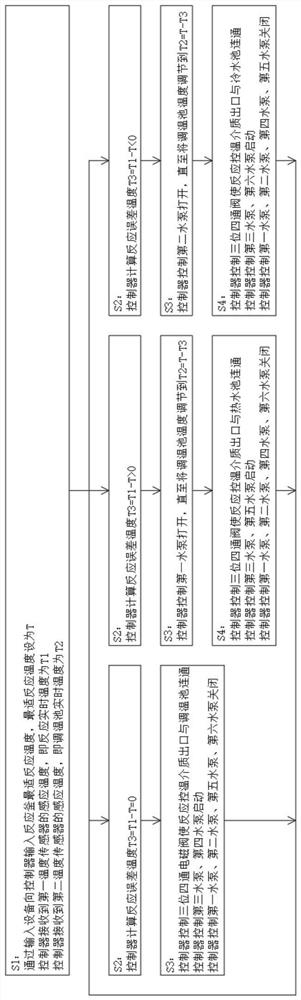

[0026] The following will be described in detail with reference to the accompanying drawings in conjunction with the embodiments of the present invention.

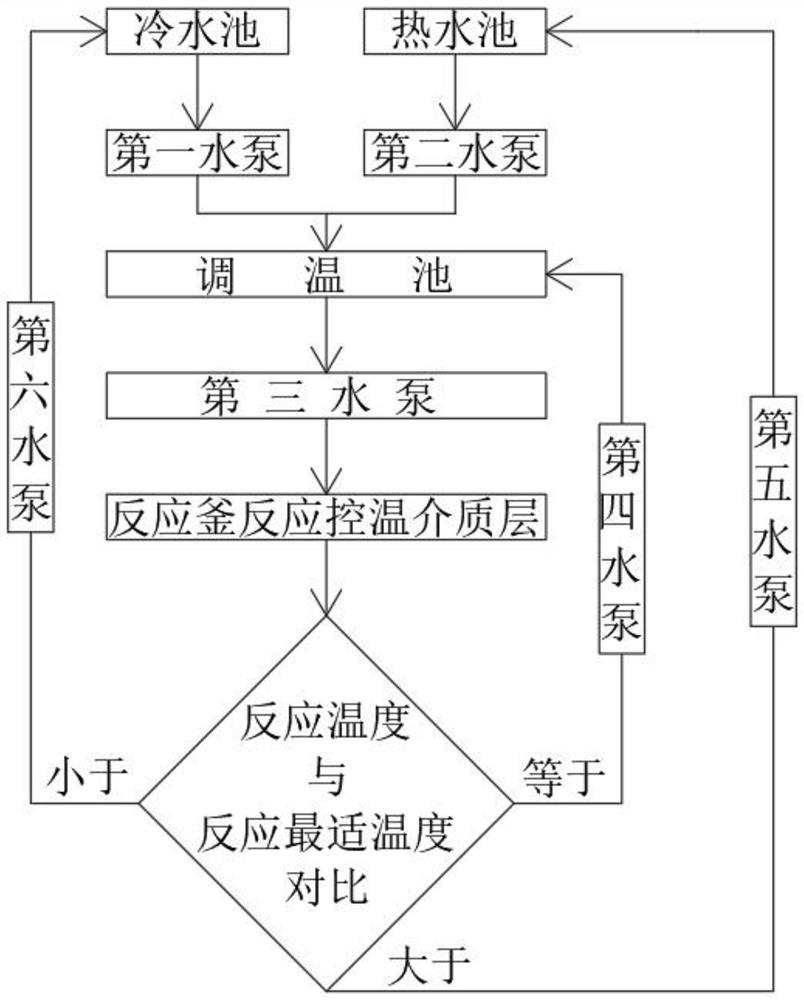

[0027] A chemical reaction temperature control and regulation system, comprising a cold water pool, a hot water pool, a temperature regulation pool, a reaction kettle and a control system; the outer layer of the reaction kettle is a temperature control medium layer;

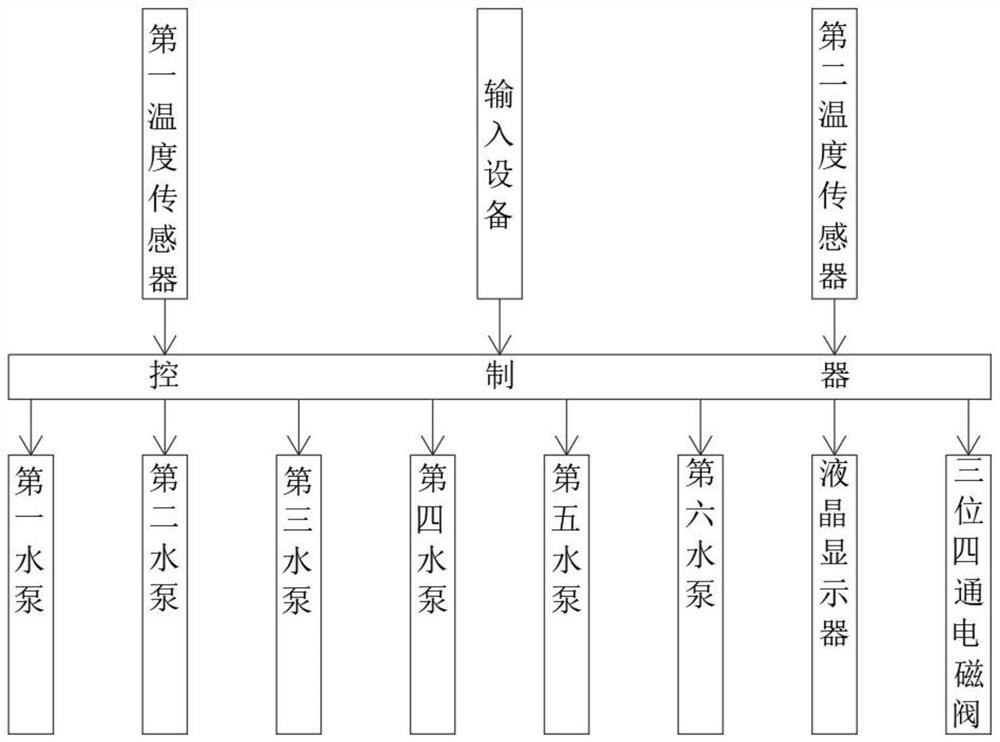

[0028] like figure 1 As shown, the control system includes a first temperature sensor, an input device, a second temperature sensor, a controller, a first water pump, a second water pump, a third water pump, a fourth water pump, a fifth water pump, a sixth water pump, and a liquid crystal display. and three-position four-way solenoid valve;

[0029] The cold water pool is connected to the temperature adjustment tank through the first water pump, the hot water tank is connected to the temperature adjustment tank through the second water pump, and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com