Noise reduction air duct of axial flow fan

An axial flow fan and noise reduction technology, applied to axial flow pumps, components of pumping devices for elastic fluids, supporting machines, etc., can solve problems such as user discomfort, loud noise, affecting work efficiency and rest quality , to achieve the effect of noise elimination, to ensure the effect of noise reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

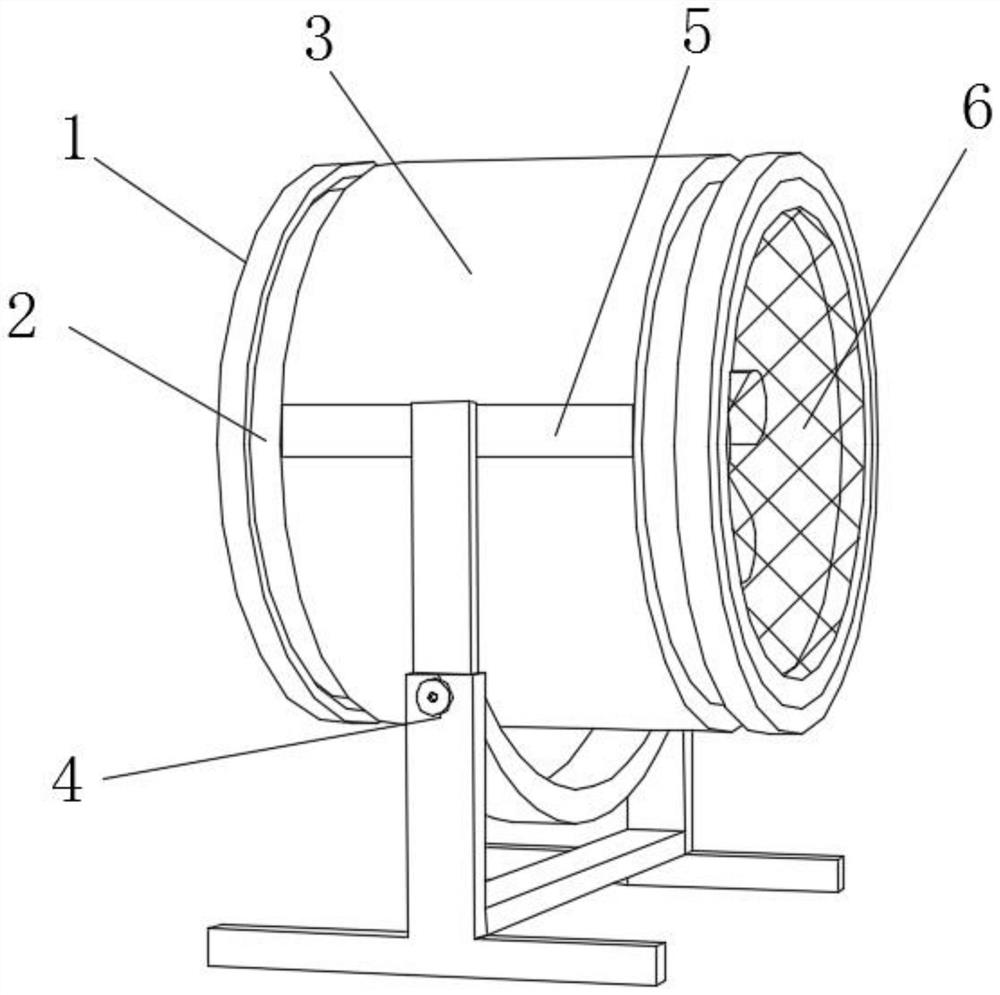

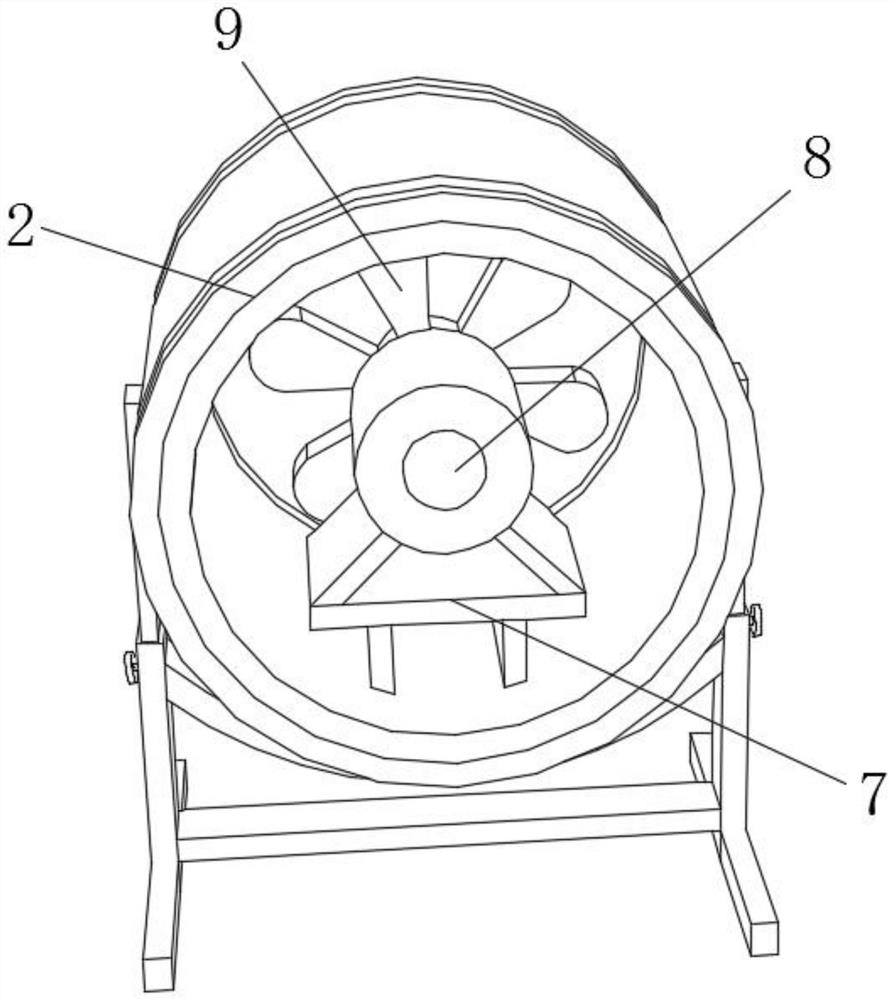

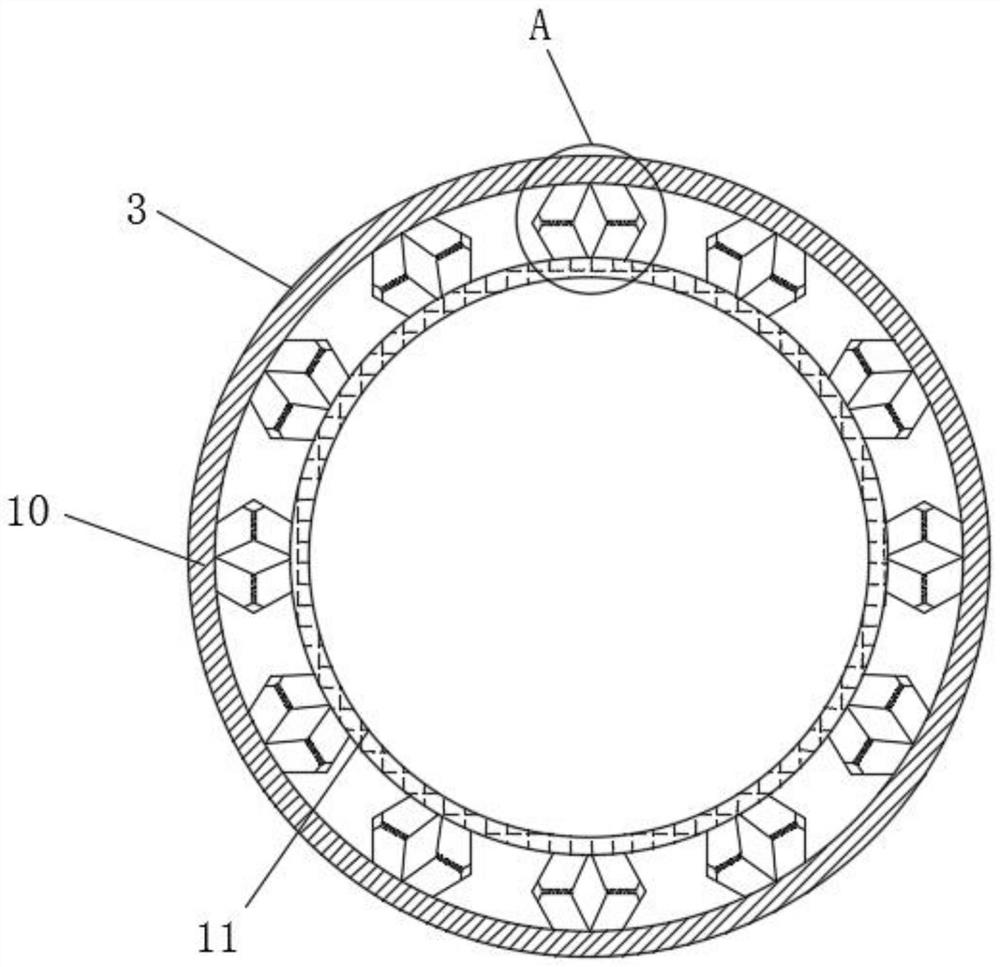

[0040] like Figure 1-7 As shown, the present invention provides a noise reduction air duct for an axial flow fan, comprising a main body device 1, an axial flow fan 2 is arranged inside the main body device 1, and an external protective sleeve 3 is arranged on the outer wall of the axial flow fan 2, A load-bearing adjustment bracket 4 is provided below the external protective sleeve 3, and the load-bearing adjustment bracket 4 is provided to play a supporting role and also to carry the vertical adjustment gear rod 25. The bearing carrier, the inside of the axial flow fan 2 is provided with auxiliary rubber The cushion layer 16 and the auxiliary rubber cushion layer 16 are provided to ensure the barrier protection between the external protective sleeve 3 and the axial flow fan 2, and the sound insulation cushion layer is protected to ensure its service life. The inner wall of the auxiliary rubber cushion layer 16 is fixedly connected There is a porous fiber sound-absorbing lay...

Embodiment 2

[0045] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the upper surface of the load-bearing adjusting bracket 4 is provided with a vertical upward moving groove 26, and the vertical upward moving groove 26 is opened to facilitate vertical Towards the movement of the adjusting gear rod 25, the inner wall of the vertical upward moving through slot 26 is movably connected with the vertical adjusting gear rod 25. The function of the vertical adjusting gear rod 25 is to support the support rod of the axial flow fan 2, and the vertical adjusting gear rod The top side of the 25 is movably connected with a horizontal reinforcing plate 5. The installation of the horizontal reinforcing plate 5 is to ensure the firmness of the connection between the vertical adjustment gear rod 25 and the axial flow fan 2, and the horizontal reinforcing plate 5 is far away from the vertical adjustment gear rod 25. One side is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com