Water tank support rotating slide way device and system, operation control method and shelving table

A water tank support and control method technology, which is applied in the directions of transportation and packaging, conveyors, vehicles with cranes, etc., can solve problems such as unsafe operation, potential safety hazards, and inability to use mixed loads, so as to prevent workpiece turnover and eliminate safety. Hidden danger and the effect of eliminating waste of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

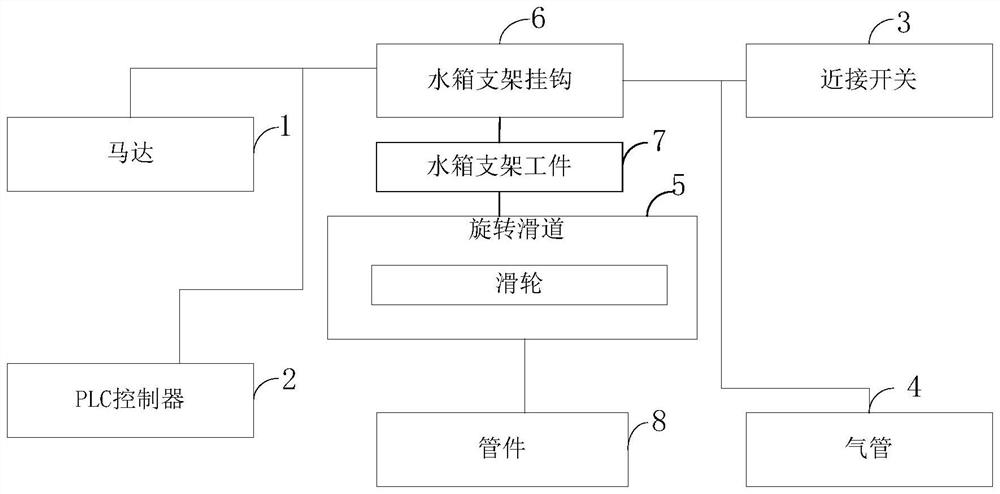

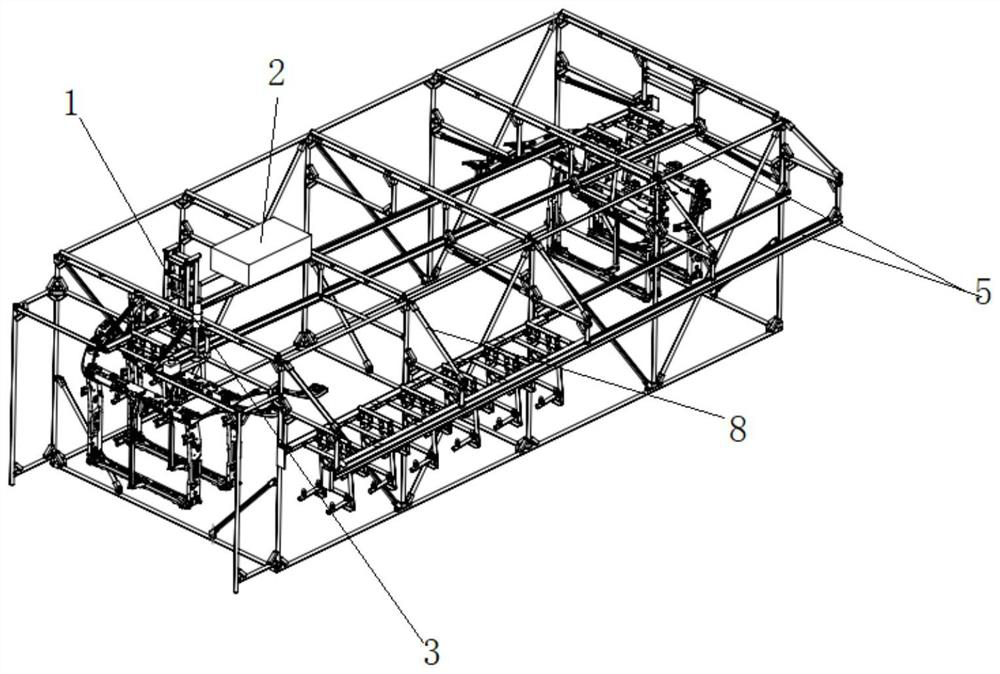

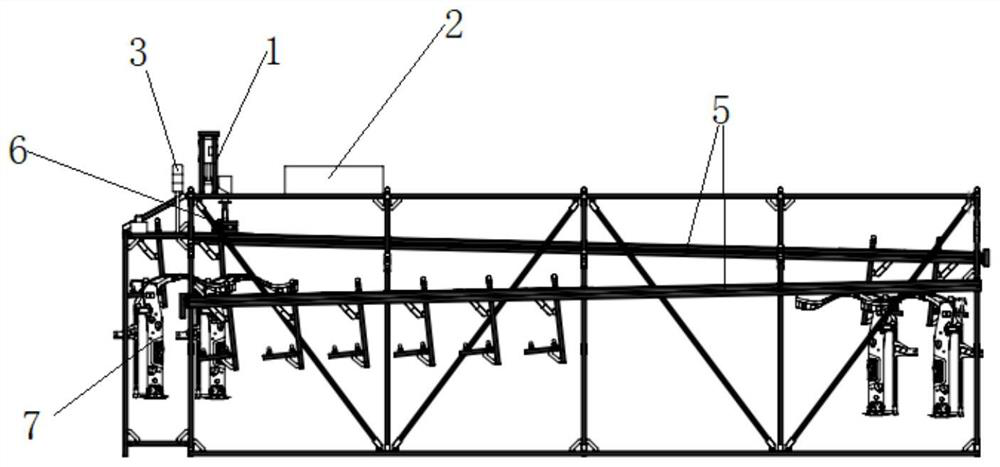

[0046] like Figure 1-Figure 4 As shown, the present invention provides a water tank support rotary slide device, comprising a motor 1, a PLC controller 2, a proximity switch 3 and a gas pipe 4, the motor 1 and the PLC controller 2 are installed on the input end of the assembled rotary slide 5 ;

[0047] A water tank bracket hook 6 is assembled above the rotating slideway 5;

[0048] The motor 1, the PLC controller 2, the proximity switch 3 and the air pipe 4 are all connected with the water tank bracket hook 6 for controlling the rotation state of the water tank bracket hook 6;

[0049] The water tank support hook 6 rests the rotating water tank support workpiece 7 on a pulley (not shown), and runs to the next process.

[0050] The pulley is installed inside the rotating slideway 5 in a rolling manner.

[0051] A pipe fitting 8 is welded to the support portion of the rotating slideway 5 .

[0052] The present invention also provides an operation control method for the wat...

Embodiment 2

[0057]The embodiment of the present invention provides a water tank support rotating slideway system, which is equipped with the rotating slideway 5, and the water tank support rotating slideway system is also equipped with a water tank support G product set table; the water tank support G product set stage will be assembled. The water tank bracket workpiece 7 is transported to the side of the rotating slideway 5; the water tank bracket hook 6 places the rotating water tank bracket workpiece 7 on the pulley, and the PLC controller 2 controls the water tank bracket hook 6 to run to the next process.

[0058] After the PLC controller 2 controls the water tank bracket hook 6 to run to the next process, it controls the first in first out of the water tank bracket workpiece.

Embodiment 3

[0060] Based on the above Embodiment 2, this embodiment of the present invention further provides a water tank bracket placement platform dedicated to different vehicle models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com