Fluid curvature engine, fluid curvature engine equipment and control method of fluid curvature engine equipment

A curvature and fluid technology, which is applied in fluid curvature engine and fluid curvature engine equipment and its control field, can solve problems such as insufficient lift and small engine thrust-to-weight ratio, and achieve the effect of increased self-control, large power load, convenient and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 Disc Fan Fluid Curvature Engine Example

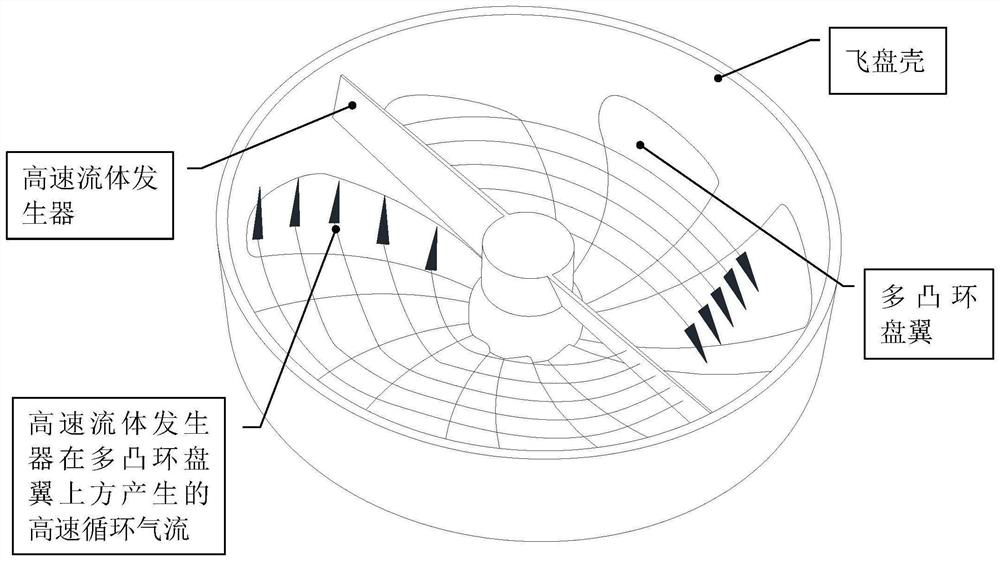

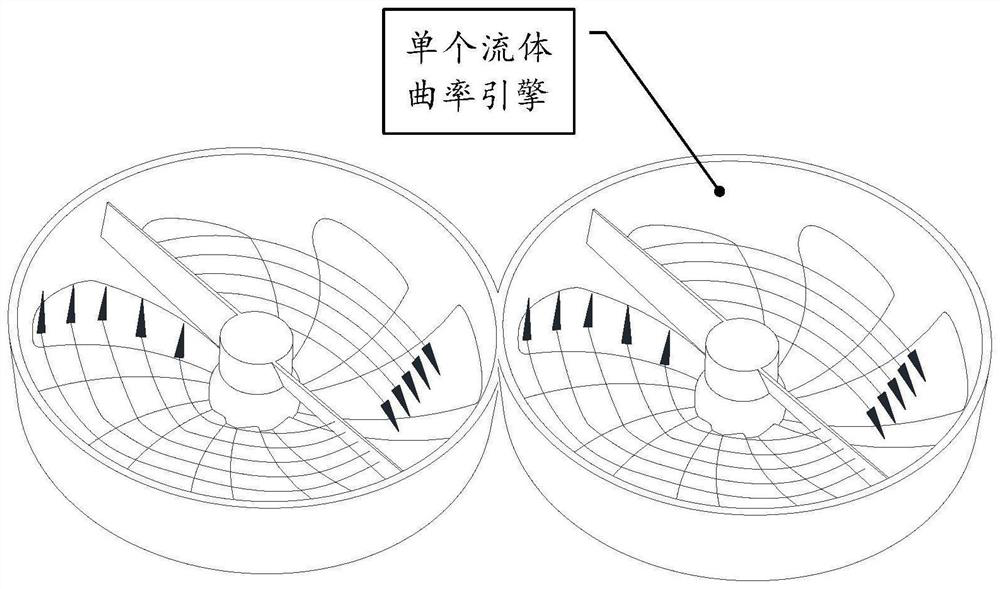

[0064] like Figure 1 to Figure 2 As shown, this embodiment provides a fluid curvature engine, specifically a disc-shaped fan fluid curvature engine, which is characterized in that it is mainly composed of a flying disc shell, a multi-convex ring disc wing, and a high-speed fluid generator. The flying disc shell is a disc-shaped open half-cavity, the multi-convex ring disc wing is disc-shaped, and the upper surface of the multi-convex ring disc wing has a plurality of protrusions with curvature radians along the circumferential fluid flow direction, Each convex curved surface with a curvature radian is similar to a single-lobed wing, and the multi-convex disc wing is equivalent to a combination of sequentially connecting multiple sections of wings in a manner of leading edge to trailing edge along the circumferential fluid flow direction. The multi-convex ring disc wing is integrated with the flying disc shell, that i...

Embodiment 2

[0066] Example 2 Polygon annular built-in generator fluid curvature engine example

[0067] like Figure 4 As shown, this embodiment provides a fluid curvature engine, specifically a multi-sided annular built-in generator fluid curvature engine, characterized in that it is mainly composed of a flying disc shell, a multi-convex ring disc wing, and a high-speed fluid generator. The flying disc shell is an annular open half-cavity, the multi-convex ring disc wing is annular, and the upper surface of the multi-convex ring disc wing has a plurality of protrusions with curvature radians along the circumferential fluid flow direction. Each convex curved surface with a curvature radian is similar to a single-lobed wing, and the multi-convex disc wing is equivalent to a combination of connecting multiple sections of wings sequentially in the manner of leading edge and trailing edge along the circumferential fluid flow direction. The multi-convex ring disc wing is integrated with the f...

Embodiment 3

[0069] Example 3 Air-collecting structure fluid curvature engine airborne equipment example

[0070] like Figure 6 to Figure 7 As shown, this embodiment provides a fluid-curvature engine airborne equipment, specifically a gas-collecting structure fluid-curvature engine airborne equipment, the high-speed fluid generator of the fluid-curvature engine is a gas-collecting structure, and the air-collecting structure is a front large Back small trumpet-shaped. When necessary, open the front end of the gas collecting structure. The gas collecting structure uses the relative high-speed motion of the fluid curvature engine equipment and the fluid to press the fluid from the front end of the large mouth, and uses its own bell mouth convergence structure or Laval tube structure to accelerate the fluid. The high-speed fluid is sprayed to the multi-convex ring disc wing in the flying disc shell from a small opening at the rear of the gas collecting structure at a certain angle. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com