Heterogeneous bionic structure design and directional energy deposition additive manufacturing method thereof

A technology of energy deposition and additive manufacturing, applied in the field of additive manufacturing, can solve problems such as insufficient manufacturing structure configuration, and achieve the effect of high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

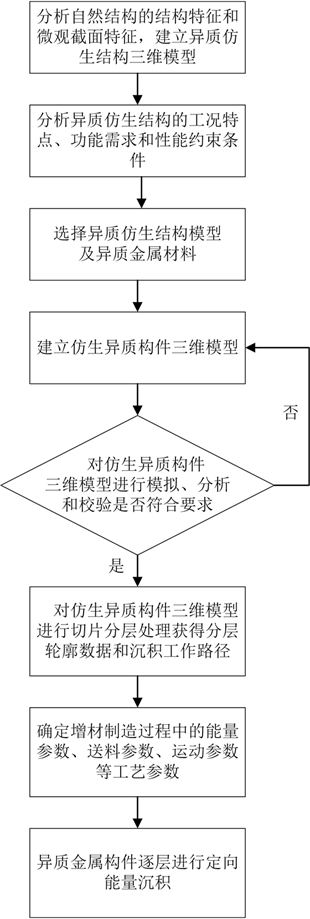

[0054] Example 1: as figure 1 As shown, a schematic flow chart of a heterogeneous biomimetic structure design and a directional energy deposition additive manufacturing method, the main steps of the present invention include:

[0055] 1) Obtain the structural features and micro-section features of the natural structure and establish a heterogeneous bionic structure model. The gradient structure inspired by bamboo can make the interface between the two materials combine to blur or disappear, so that the performance changes with the composition and structure. Gradient change, avoiding the problems of sudden performance, stress concentration, mismatch, etc. Its heterogeneous bionic gradient structure model is such as figure 2 shown;

[0056] 2) According to the actual bearing environment and working conditions, determine the working characteristics, functional requirements and performance constraints required for heterogeneous metal components. For aerospace components, ultra-h...

Embodiment 2

[0067] Embodiment 2: A schematic flow diagram of a heterogeneous biomimetic structure design and a directed energy deposition additive manufacturing method, such as figure 1 As shown, the main steps of the present invention include:

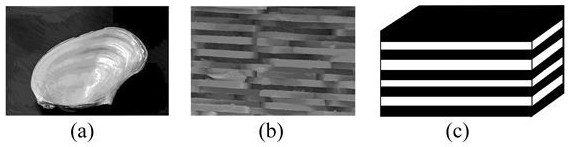

[0068] 1) Obtain the structural characteristics and micro-section characteristics of natural structures and establish a heterogeneous bionic structure model. The layered structure inspired by shells has the characteristics of high toughness and high strength, which can improve the overall performance of heterogeneous components. Biomimetic hierarchical structure models such as image 3 shown;

[0069] 2) According to the actual load-bearing environment and working conditions, determine the working characteristics, functional requirements and performance constraints required for heterogeneous metal components. For gear components, it should meet the working conditions in harsh environments such as wear resistance and corrosion resistance. ;

[...

Embodiment 3

[0080] Example 3: A schematic flowchart of the design of a heterogeneous biomimetic structure and its directional energy deposition additive manufacturing method, such as figure 1 As shown, the main steps of the present invention include:

[0081] 1) Obtain the structural features and micro-section features of natural structures and establish a heterogeneous bionic structure model. The interlocking structure inspired by beetle elytra can improve the toughness, impact resistance and extrusion resistance of heterogeneous components. Interlocking structure models such as Figure 4 shown;

[0082] 2) According to the actual bearing environment and working conditions, determine the working condition characteristics, functional requirements and performance constraints required for heterogeneous metal components. For nuclear power chemical components, it should meet the work in harsh environments such as high temperature resistance and corrosion resistance. condition;

[0083] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com