Automatic shell withdrawing device for stretching forming of battery steel shell

A technology of stretch forming and battery steel shell, which is applied in the direction of forming tools, final product manufacturing, manufacturing tools, etc. It can solve the problems that affect the ejection of the return spring, there is no lubrication device in the forming hole, and affect the shell ejection process, so as to improve the processing efficiency. , the effect is good, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

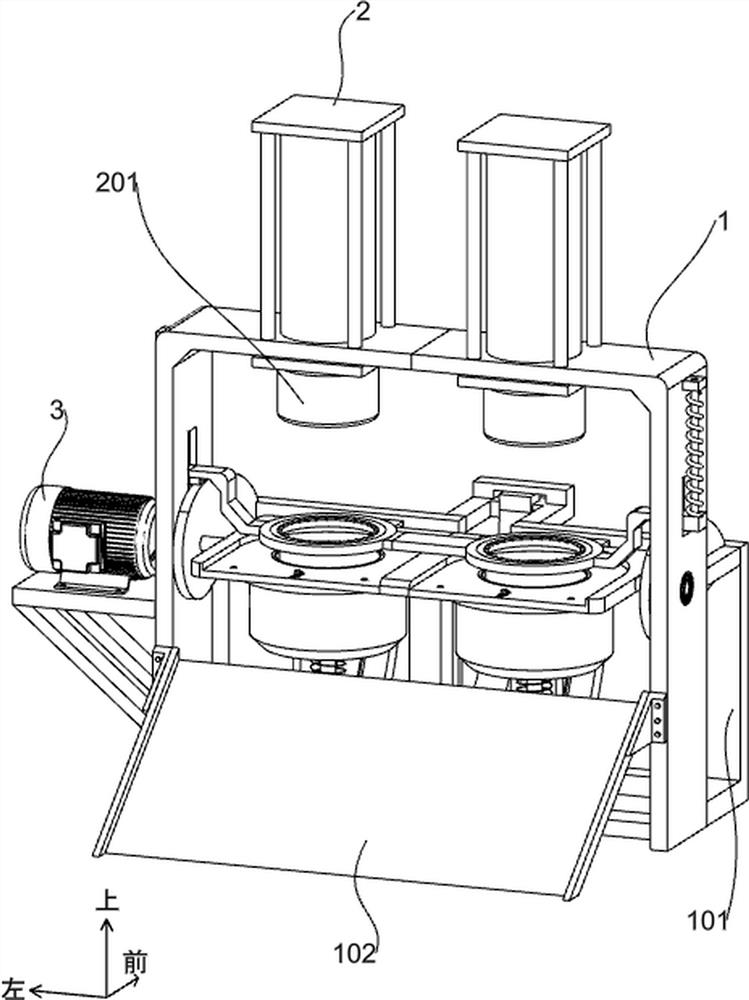

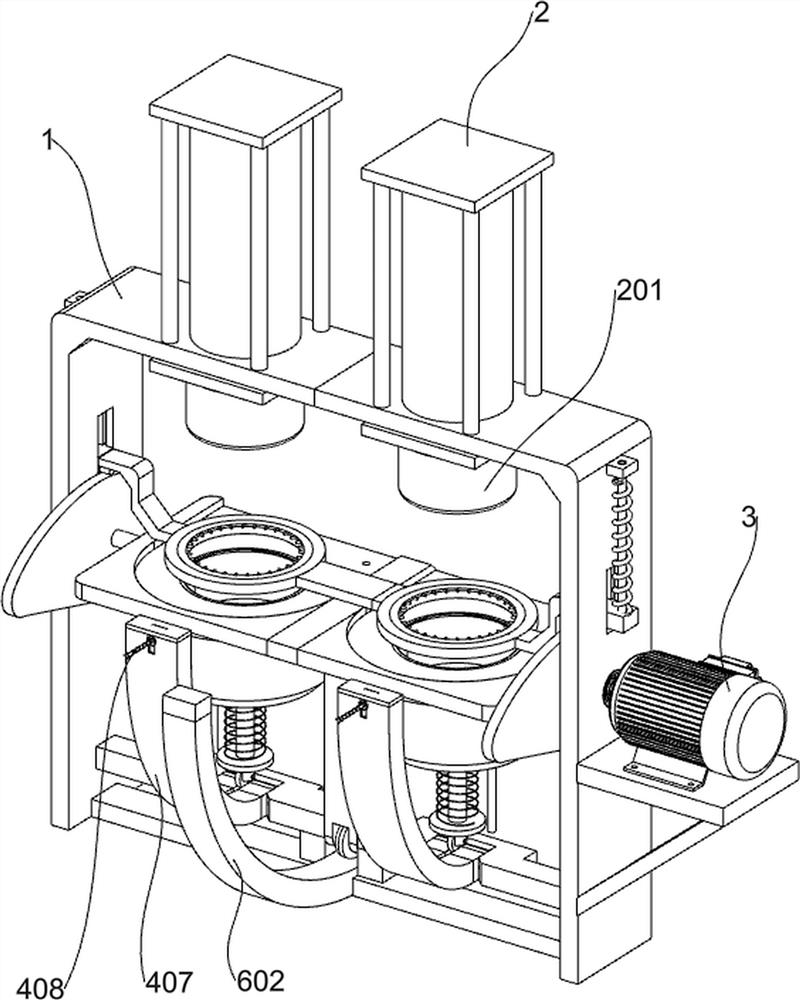

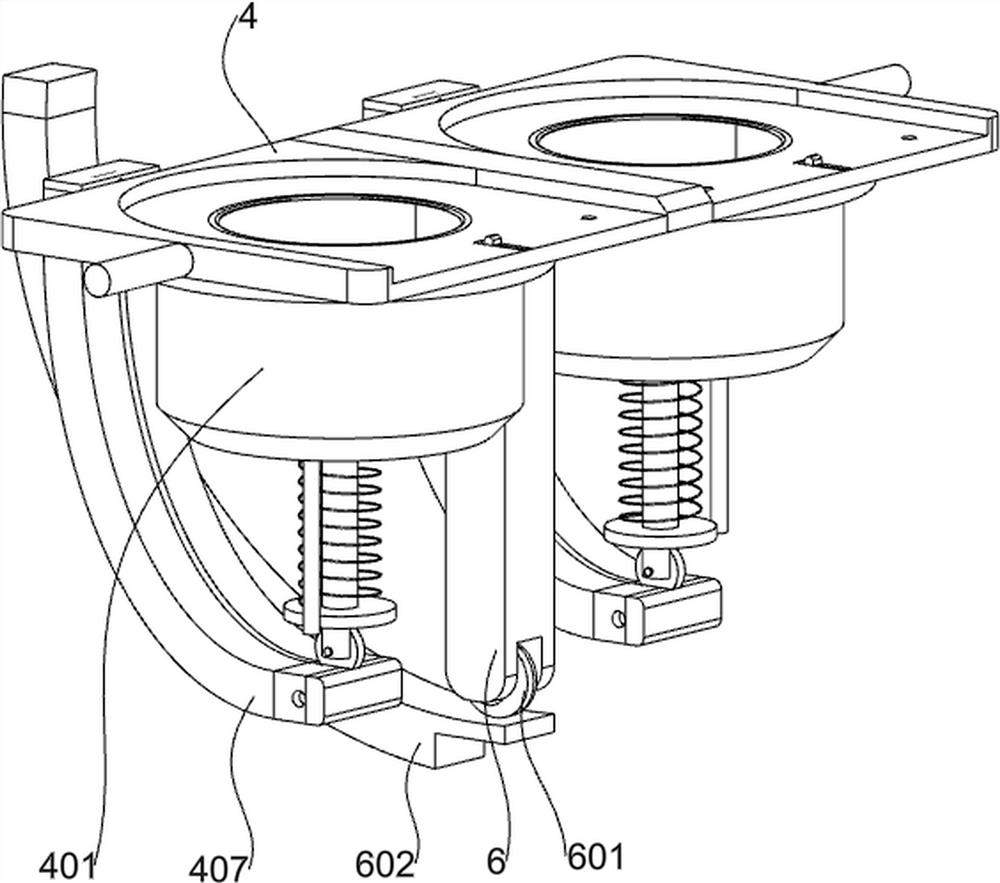

[0036] A battery steel shell stretching forming automatic shell removal device, such as Figure 1-4 As shown, it includes a support frame 1, a back plate 101, a swash plate 102, a cylinder 2, an upper stamping die 201, a motor 3, a stamping plate 4, a lower die 401, a push block 402, a sliding rod 403 and an unpacking assembly, the support frame 1. A back plate 101 is fixedly connected to the rear side, a sloping plate 102 is fixedly connected to the front side of the support frame 1, a cylinder 2 is installed on the upper side of the support frame 1, and an upper stamping die 201 is fixedly connected to the protruding end of the cylinder 2, and the support frame 1 rotates inside A stamping plate 4 is connected, a motor 3 is installed on the left side of the support frame 1, the output shaft of the motor 3 is fixedly connected with the stamping plate 4, the stamping plate 4 is fixedly connected with a lower die 401, and the lower die 401 is provided with a shell-removing compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com