New energy automobile battery pack frame structure

A new energy vehicle and frame structure technology, applied in structural parts, electric vehicles, secondary batteries, etc., can solve the problems of lithium-ion battery short circuit, battery pack extrusion damage, incineration, etc., to reduce direct collisions and lower battery temperature , the effect of increasing the activity space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the structural features and effects of the present invention more clearly, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

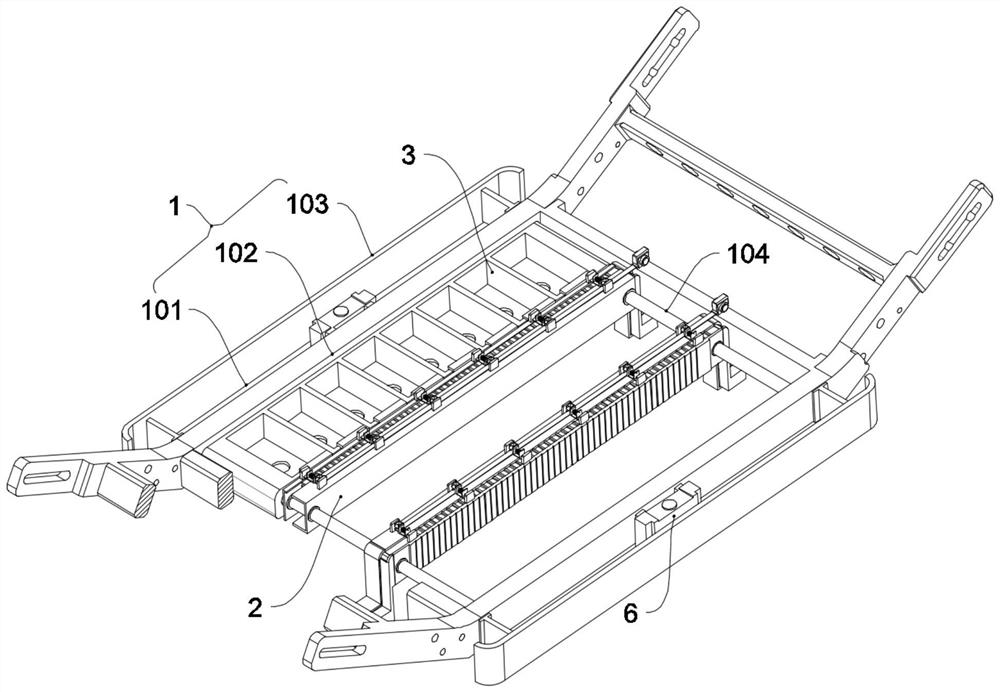

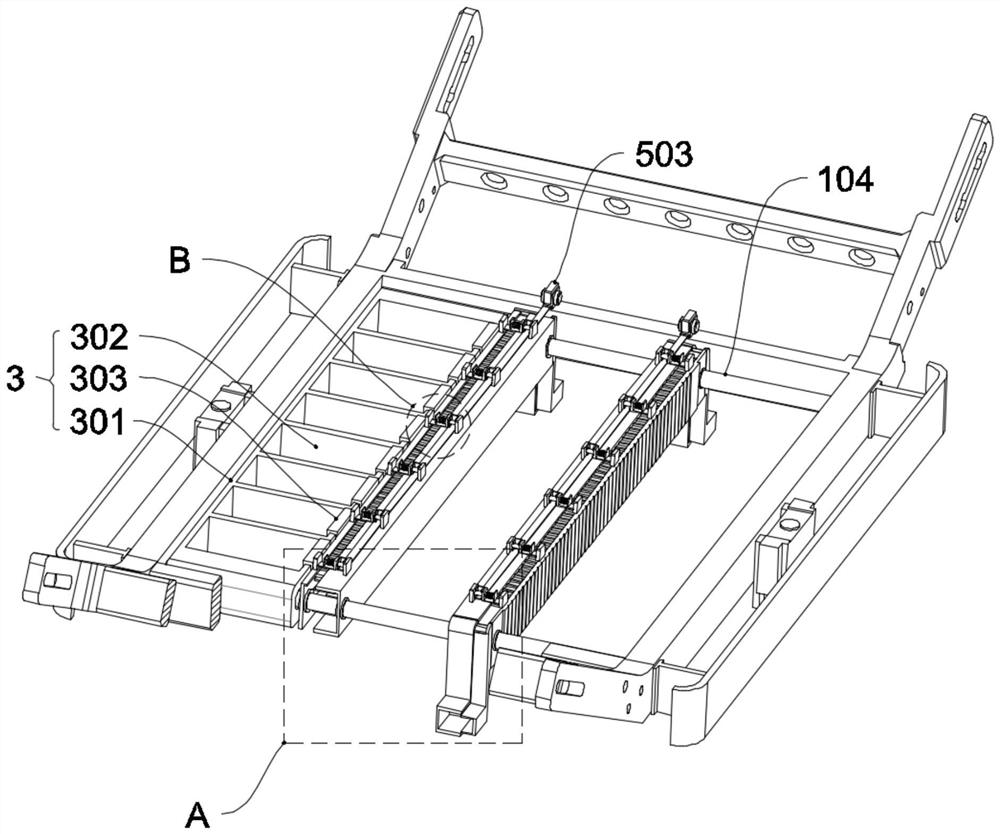

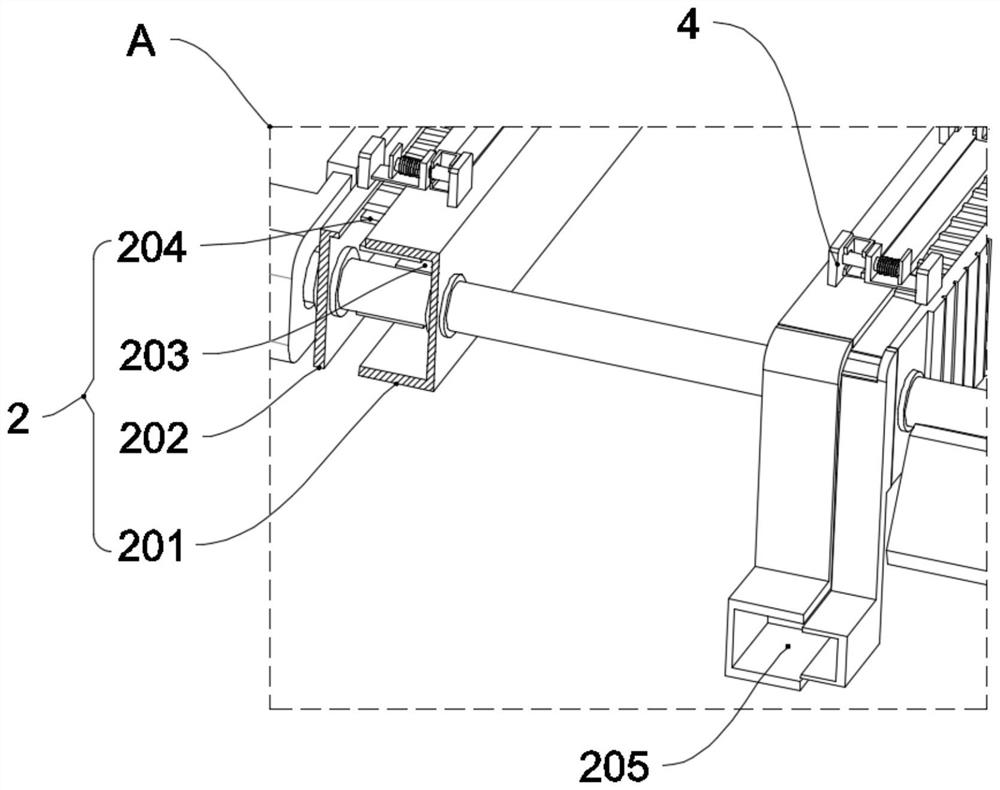

[0029] see Figure 1-Figure 5 , the frame structure of a battery pack for a new energy vehicle in an embodiment of the present invention includes a frame member 1, the frame member 1 includes a main frame 101, an inner groove 102 and a guide post 104, and the main frame 101 is internally arranged There is an inner groove 102, two guide posts 104 are assembled in parallel in the inner groove 102, and the arrangement direction of the guide posts 104 is perpendicular to the front direction of the main frame 101; the air guide member 2, the battery pack frame The structure includes several groups of air guide members 2, the air guide members 2 include a first C-shaped groove shell 201 and a second C-shaped groove shell 202, and the first C-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com