Implementation method of multi-PLC parallel test

An implementation method and technology of test cases, applied in the field of automation, can solve problems such as single function and difficulty in multi-PLC joint testing, and achieve the effect of improving testing efficiency and testing ability, and realizing online modification and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation method of the present invention will be described in detail below with reference to the accompanying drawings.

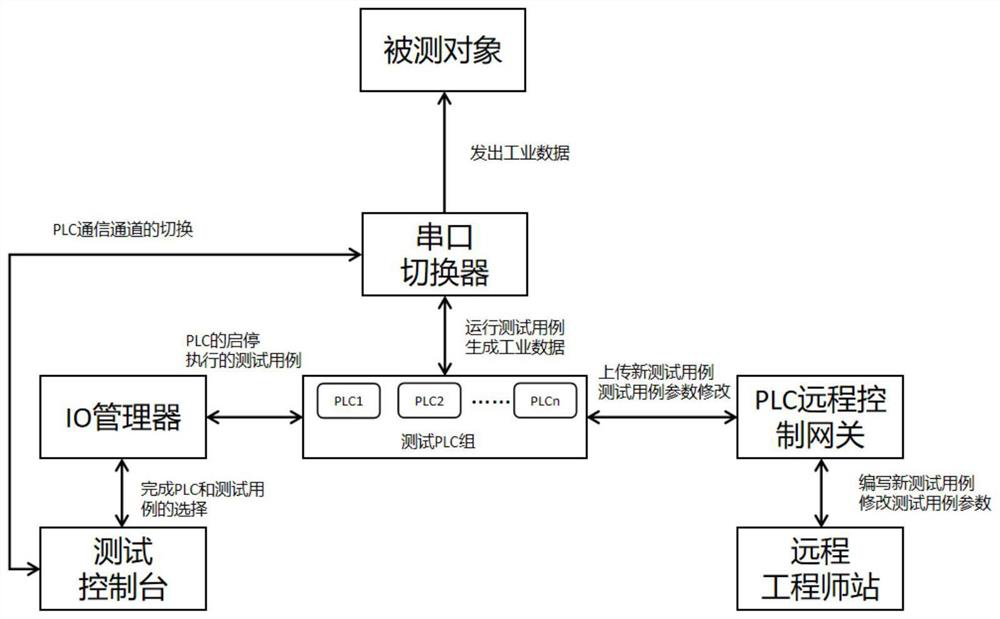

[0022] The present invention is a method for realizing parallel testing of multiple PLCs. The multiple PLCs are connected with a remote control gateway, and a remote engineer station is used to construct a PLC test case, and the PLC and the test to be run are completed on the test console. Use case selection to achieve test control under multi-PLC parallel.

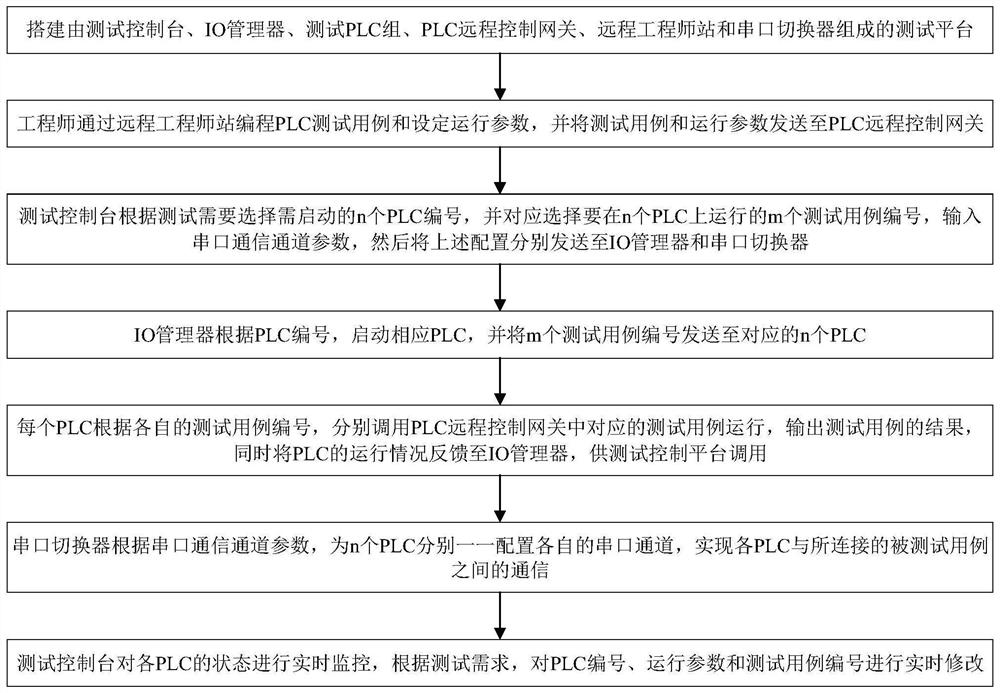

[0023] like figure 1 shown, the specific steps are as follows:

[0024] Step 1. Build a test platform consisting of test console, IO manager, test PLC group, PLC remote control gateway, remote engineer station and serial port switcher;

[0025] like figure 2 As shown in the figure, the IO manager is connected to the test console through the network, and is connected to the test PLC group through hard wiring; the test PLC group is connected to the PLC remote control gateway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com