Intelligent cloth inspecting machine

A fabric inspection machine, intelligent technology, applied in the direction of folding thin materials, thin material processing, optical testing flaws/defects, etc., can solve the problems of easy fatigue, easy leakage points, unfavorable cloth processing work, etc., to improve inspection effect, ease of installation work, and effect of improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

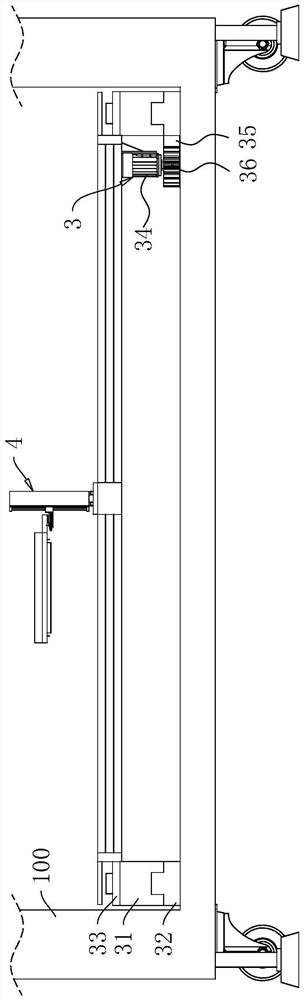

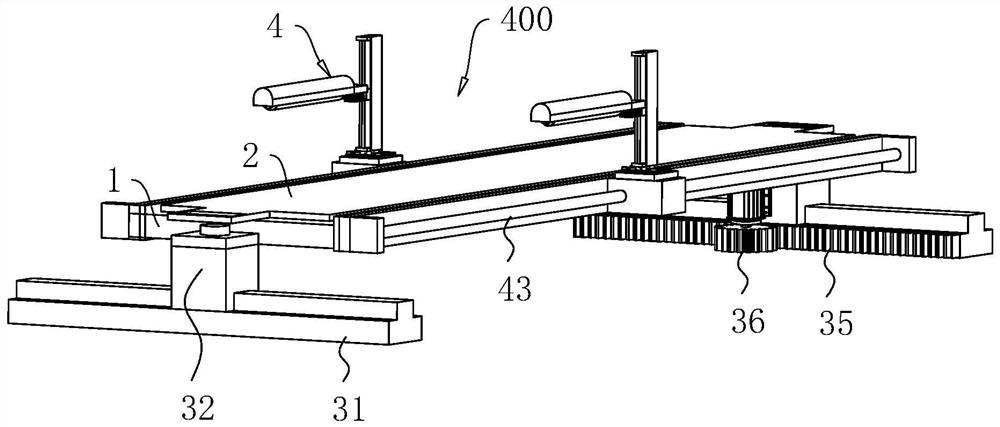

[0040] Attached to the following Figure 1-7 This application will be described in further detail.

[0041] The embodiment of the present application discloses an intelligent cloth inspection machine.

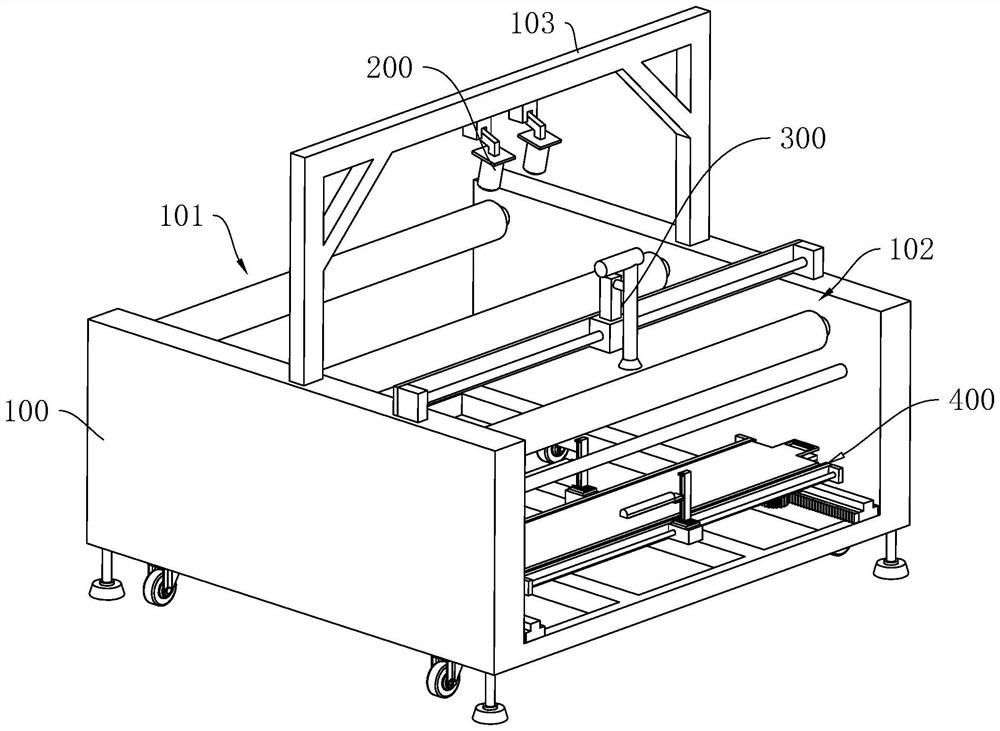

[0042] refer to figure 1 , the intelligent cloth inspection machine includes a body 100 , an image acquisition camera 200 , a labeling device 300 and a cloth receiving device 400 . Wherein, the two ends of the body 100 are respectively provided with a feeding end 101 and a feeding end 102 . During the cloth inspection process, the cloth is conveyed from the feeding end 101 to the feeding end 102 . A camera frame 103 is fixed on the top of the body 100 , and the camera frame 103 is located between the feeding end 101 and the discharging end 102 ; the number of image capturing cameras 200 is two groups, and the two groups of image capturing cameras 200 are installed at intervals on the top of the camera frame 103 , to capture the defects in the conveyed cloth, and at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com