Cast-in-place greening concrete construction method for inland waterway

A technology for greening concrete and construction methods, applied in the directions of botanical equipment and methods, applications, infrastructure engineering, etc., can solve the problems of short service life, piping, poor structural stability, etc., to reduce leaching and erosion, reduce wear and tear and cost, and the effect of preventing landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

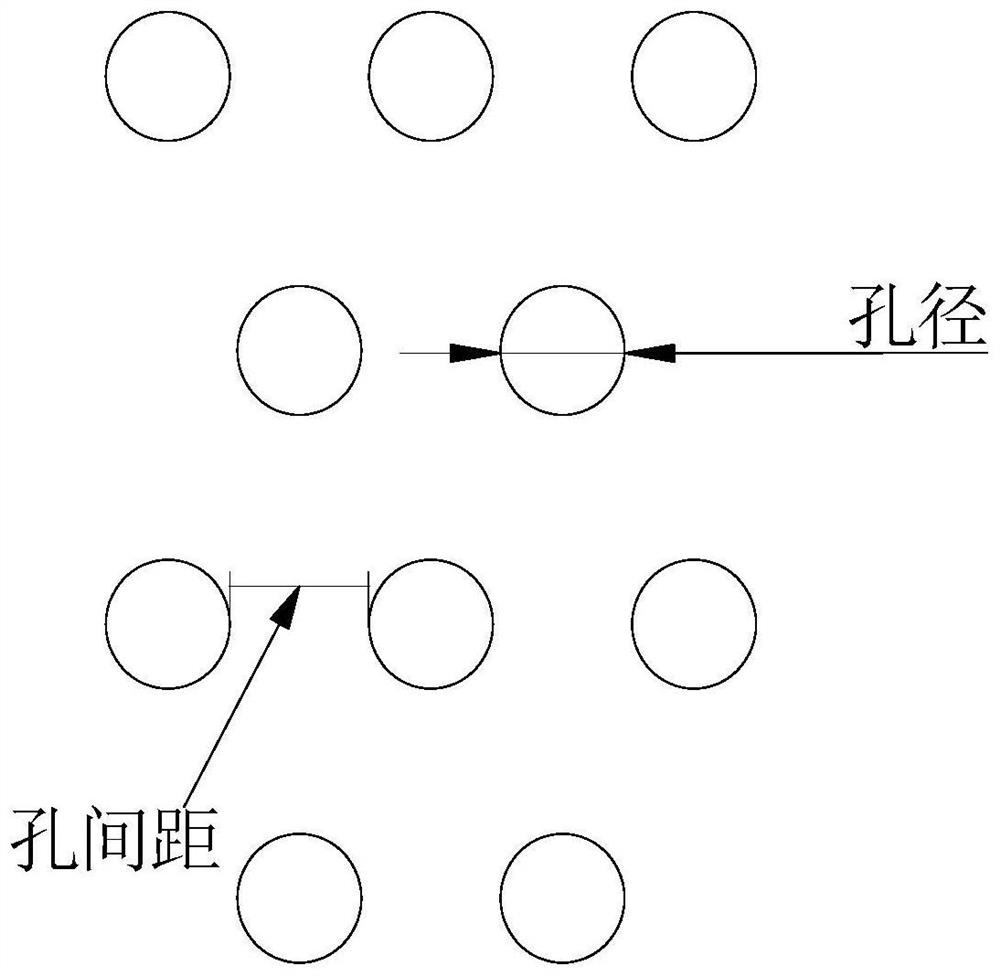

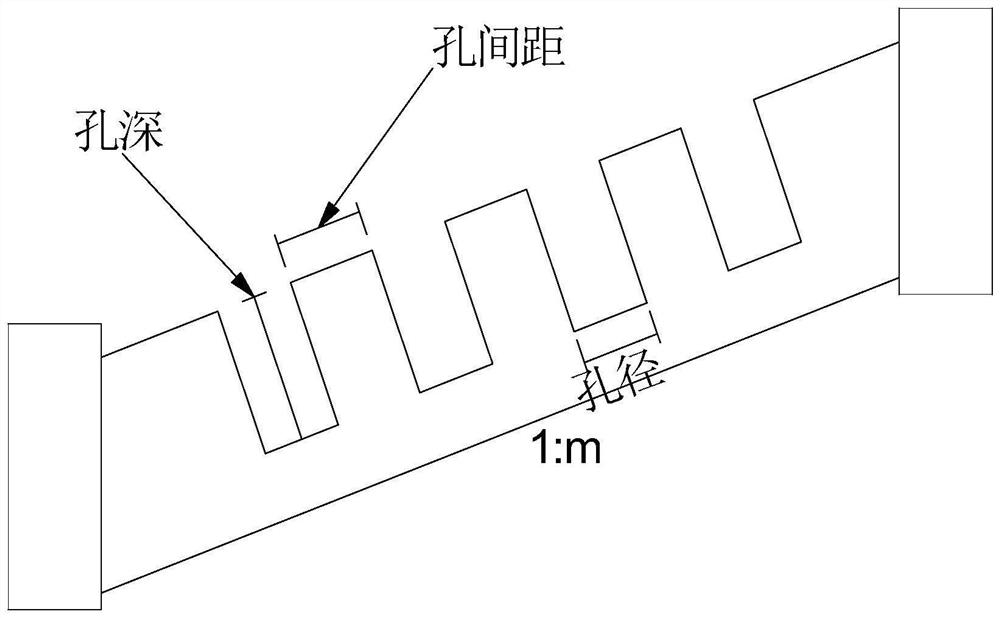

[0033] A cast-in-place greening concrete construction method for inland waterways, such as figure 1 , figure 2 shown, including the following steps:

[0034] 1) Make a cube mold with a length, width and height of 1m × 1m × 0.3m to simulate the slope, which can be supported by brackets and adjusted to different slopes. The soil quality of the simulated slope is clay, and the slope is 1:1.5. Lay 15cm thick clay in the mold, level and compact it with a compactor, and brush oil on the inner surface of the mold;

[0035] 2) Weigh the following components and masses and prepare them in order: 600 parts of aggregate, 120 parts of P.O 42.5 cement, 60 parts of water and 4 parts of special admixtures, the special admixtures are provided by Shanghai Jiuding Green Concrete Co., Ltd. Cast-in-place greening concrete with a thickness of 11cm is poured in the slope mold;

[0036] 3) Within 30 minutes after the completion of the pouring, use the drilling machine to open surface holes with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com