Magnetized water structure and magnetized water production equipment with same

A technology of magnetized water and magnetic blocks, which is applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve the problems of loss of water flow rate, inability to quickly adjust magnetized water and non-magnetized water, and inability to produce magnetized water with magnetization intensity, and achieves a high level of improvement. The degree of intelligence and the effect of overcoming the loss of water flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

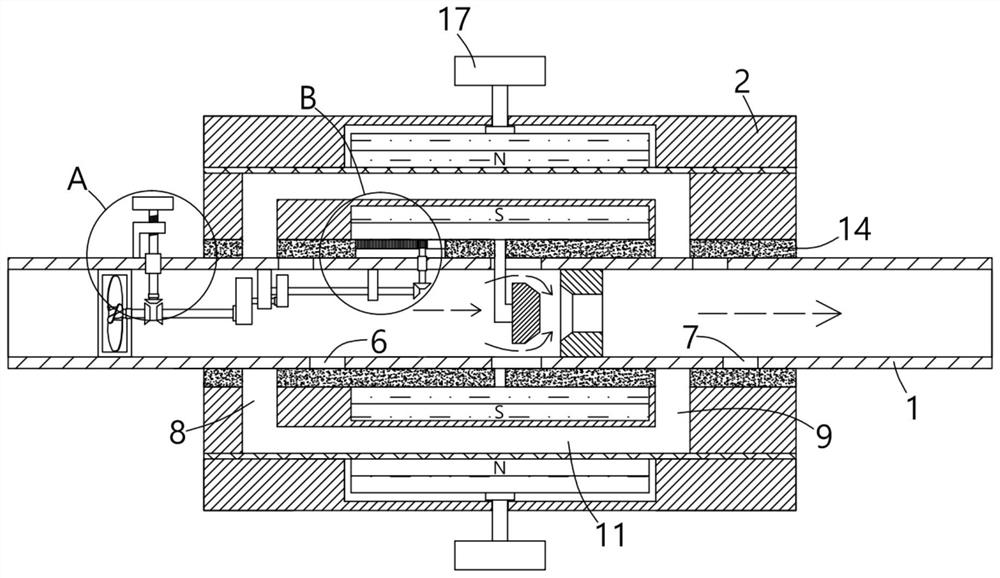

[0034] A magnetized water structure, comprising a confluence pipe 1, a magnetized water slide sleeve 2 is slidably sleeved on the outside of the confluence pipe 1, a sliding groove 3 is formed in the middle of the confluence pipe 1, and the magnetized water slide sleeve 2 is fixedly installed in the middle. The sliding groove 3 extends to the sealing block 4 inside the collecting pipe 1, and the sealing block 4 cooperates with the rubber ring 5 arranged inside the collecting pipe 1. The upper and lower sides of the collecting pipe 1 are also provided with magnetized water inlet holes 6 that penetrate inside and outside. The magnetized water outlet hole 7, the magnetized water inlet hole 6 and the magnetized water outlet hole 7 are respectively located on both sides of the rubber ring 5, and the magnetized water inlet hole 6 and the magnetized water outlet hole 7 are respectively opened with the upper and lower sides of the magnetized water sliding sleeve 2. The water inlet 8 an...

Embodiment 2

[0038] In this embodiment, a rubber sealing ring 14 is provided inside the magnetized water sliding sleeve 2 and the collecting pipe 1 on one side, and the magnetized water inlet hole 6 , the magnetized water outlet hole 7 and the The sliding groove 3 is blocked to prevent the water body from flowing out through the aforementioned channel.

Embodiment 3

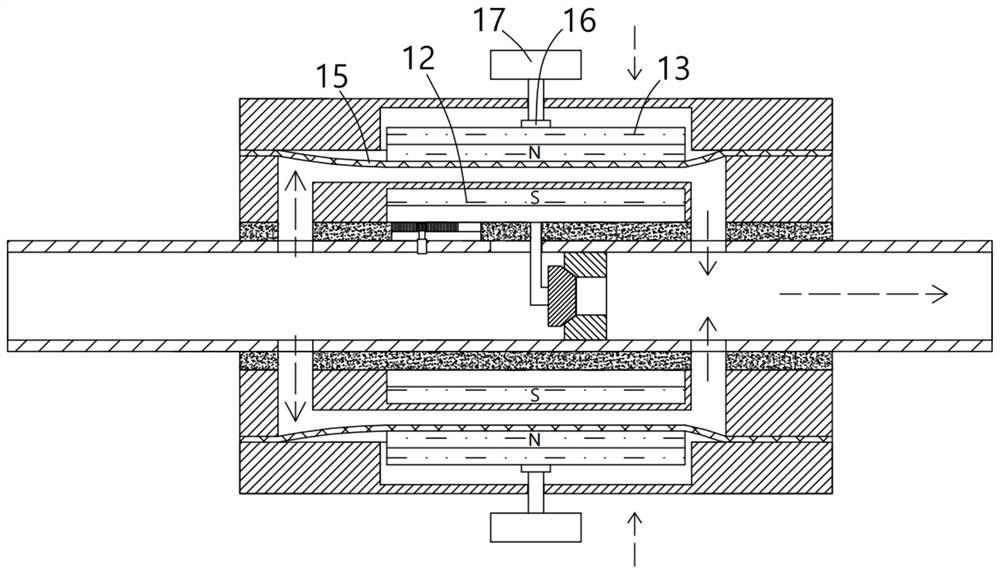

[0040] In this embodiment, the upper and lower movable magnetic blocks 13 are connected with flexible PVC spacers 15 on one side close to the fixed magnetic block 12 . The movement of the magnetic block 13 drives the flexible PVC partition layer 15 to expand and contract, and the flexible PVC partition layer 15 blocks the outflow of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com